Coreless motor stator glue pouring and shaping mechanism

A hollow cup stator and motor stator technology, applied in the field of spacecraft, can solve the problems of glue filling, shaping difficulty, coil springback, uneven distribution of wires, etc., and achieve the effect of compact structure, easy operation and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

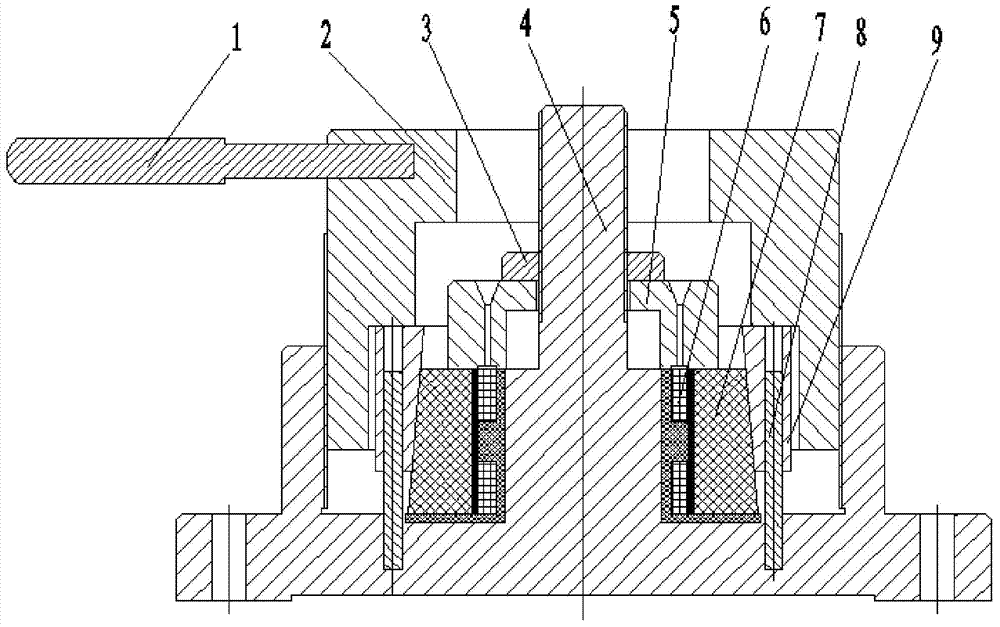

[0030] Such as figure 1 As shown, the hollow cup motor stator glue filling and shaping mechanism includes a handle 1, a lock nut 2, a pressure ring nut 3, a base 4, a pressure ring 5, a hollow cup stator 6, a shaping block 7, two positioning pins 8 and Taper sleeve 9;

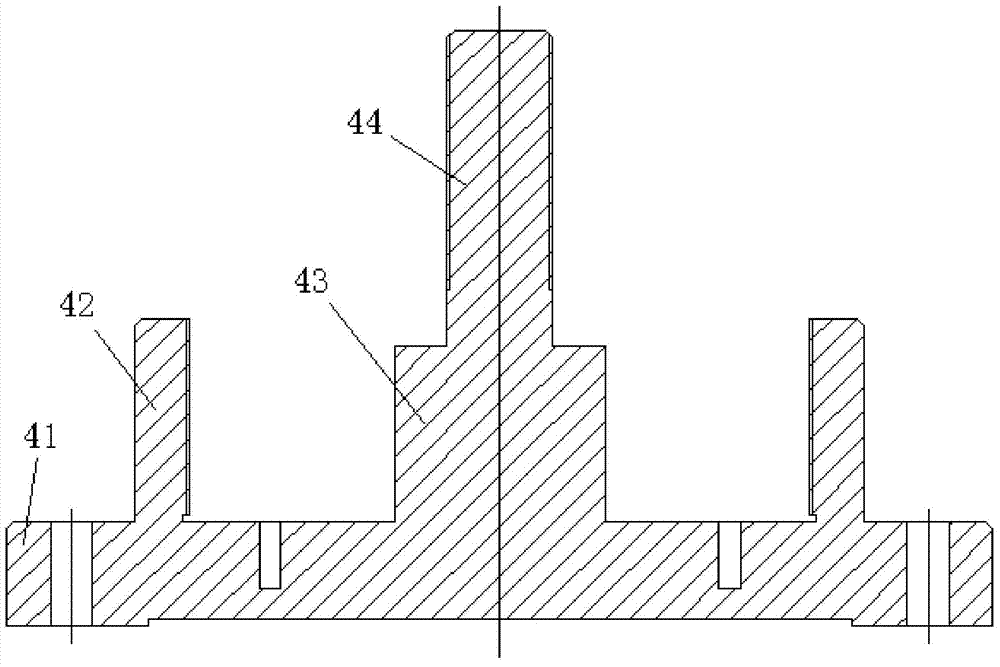

[0031] Such as figure 2 Shown, the bottom of described base 4 is cylinder 41, and there is an annular boss 42 on the cylinder, and the inner wall of annular boss 42 has internal thread; There is a stud 44 above the platform 43;

[0032] The pressure ring 5 is set on the stud 44 part of the base 4, and adopts clearance fit;

[0033] The hollow cup stator 6 is sleeved on the cylindrical boss 43 of the base 4, the outer diameter of the cylindrical boss 43 of the base 4 is the same as the inner diameter of the hollow cup stator 6, and the cylindrical boss 43 of the base 4 is used for hollow The cup stator 6 is used for positioning when pouring glue and shaping;

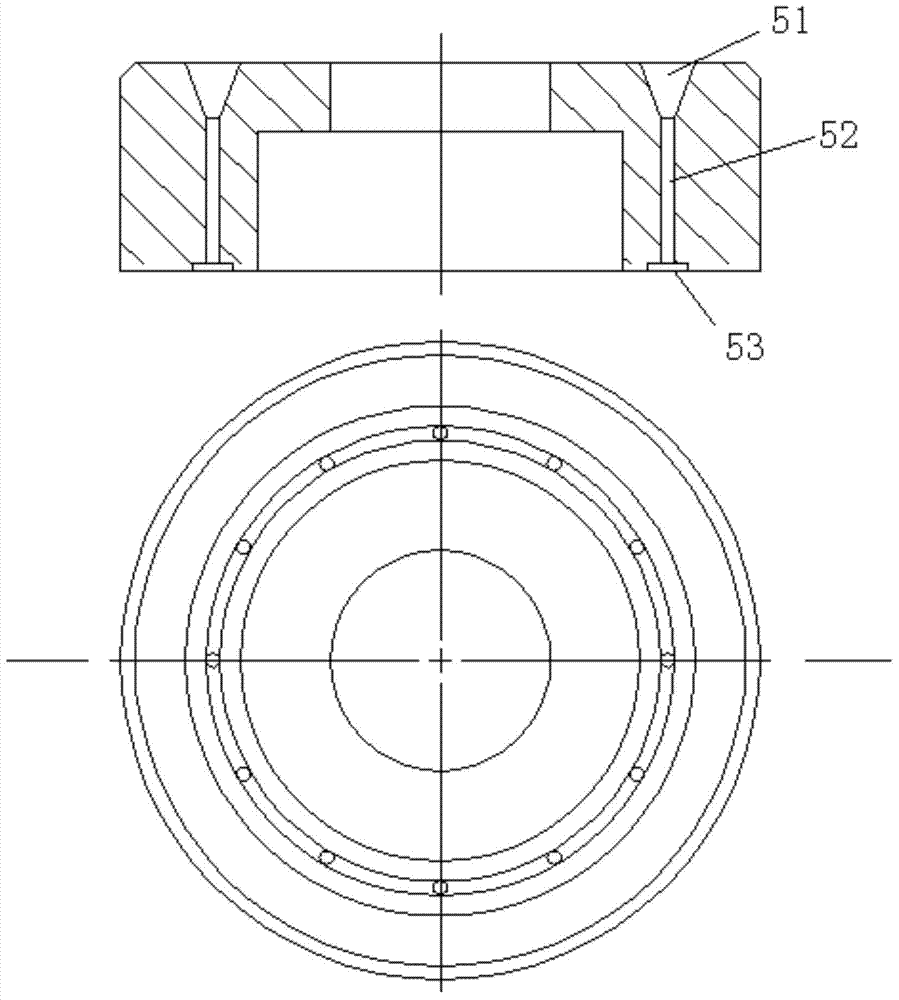

[0034] The pressure ring nut 3 is sleeved on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com