Reactor core with high fast neutron fluence

A fast neutron and fluence rate technology, applied in the direction of moderator/core structure, reactor, nuclear power generation, etc., can solve the problems of limiting core power density and neutron fluence rate level, and achieve enhanced irradiation Capability and application range, high practical value, effect of high irradiation capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

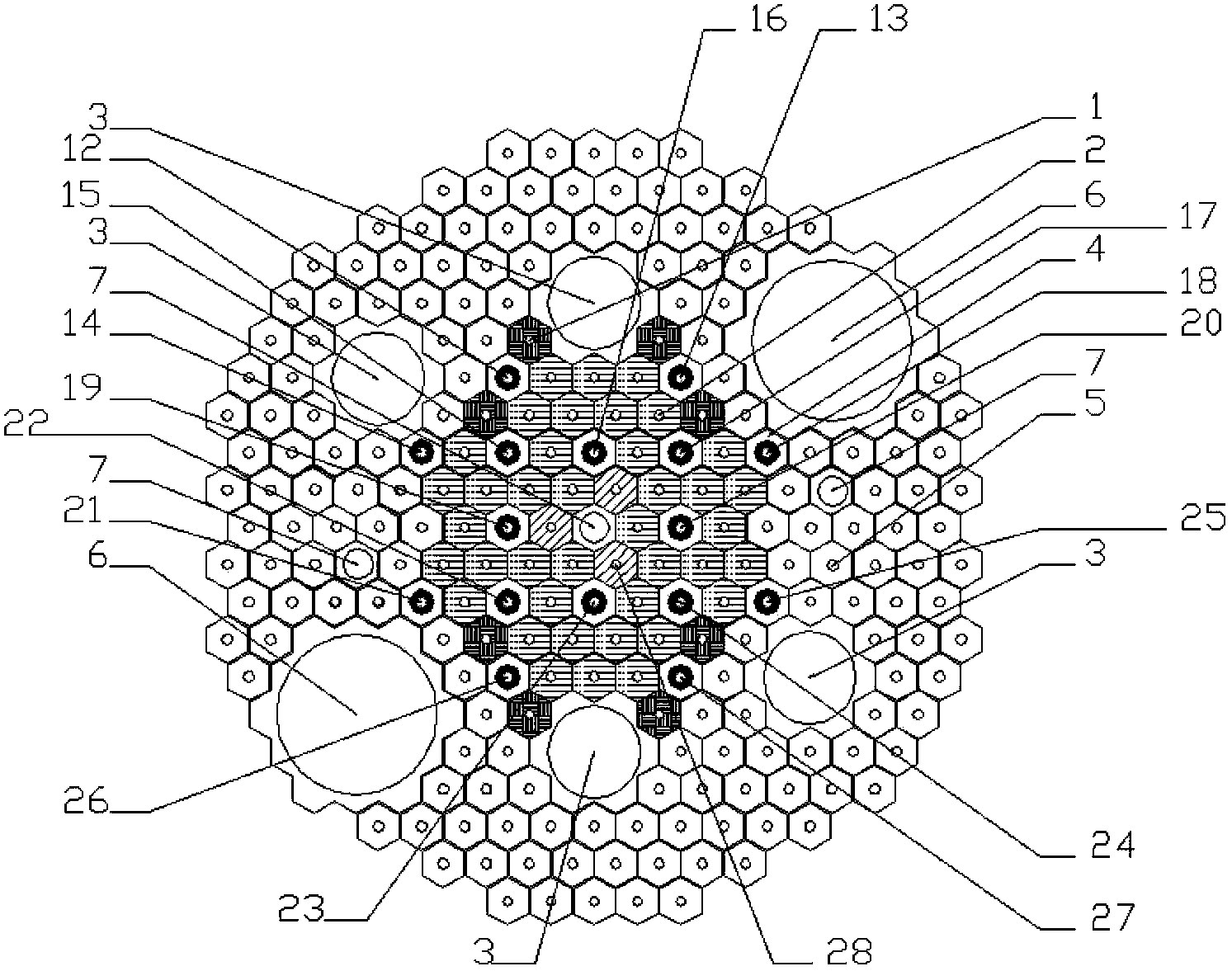

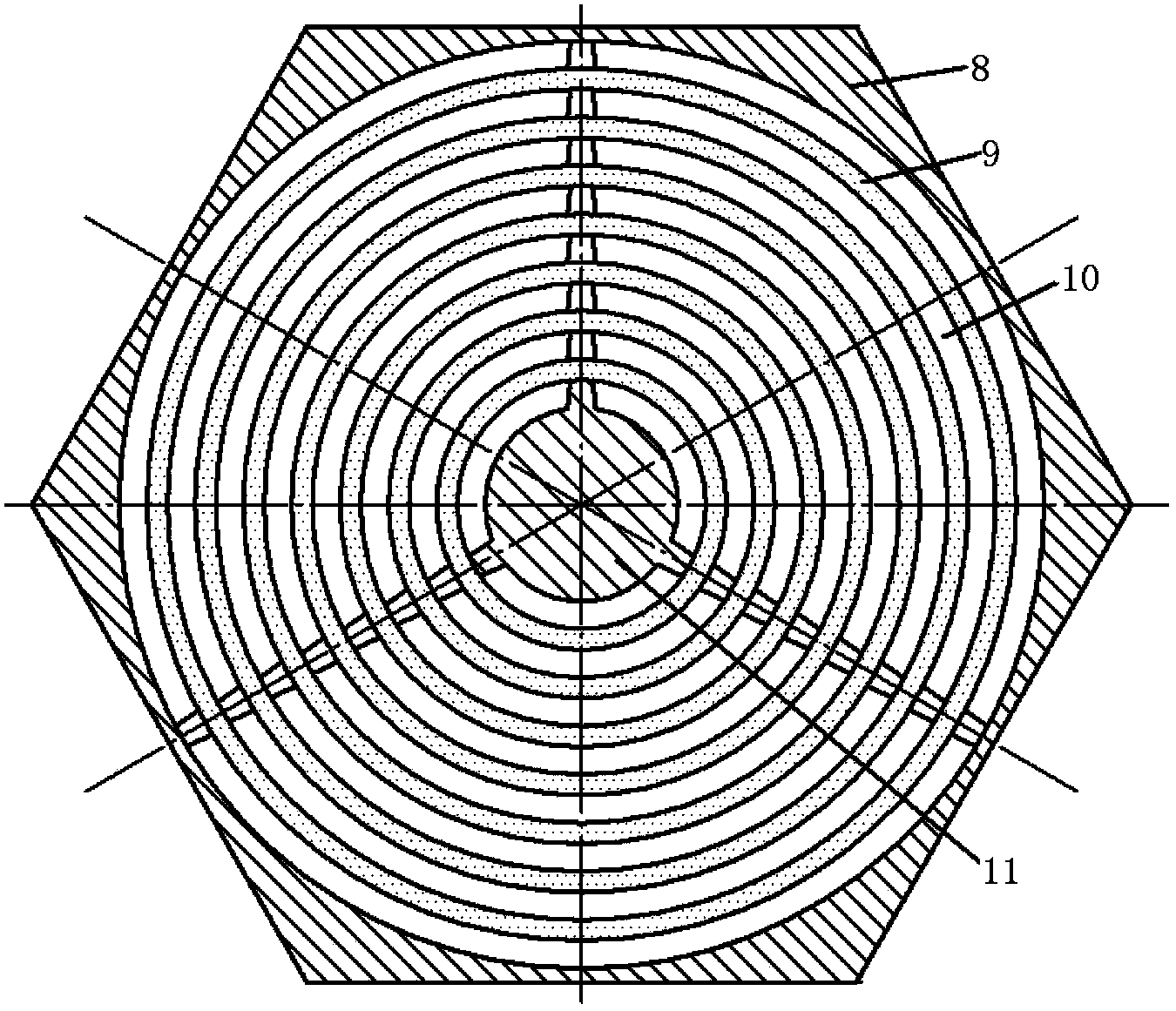

[0033] Such as figure 1 As shown, the high-fast neutron fluence rate core of the present invention includes a cobalt target 1, a seven-layer fuel assembly 2, a medium irradiation tunnel 3, a control rod assembly 4, a beryllium assembly 5, a large irradiation tunnel 6 and a small irradiation tunnel. According to the hole 7; the seven-layer fuel assembly 2 is a hexagonal casing type fuel assembly, and 42 seven-layer fuel assemblies 2 are arranged in a compact ring, and there are 6 seven-layer fuel assemblies 2 on the innermost ring. A fast neutron trap is formed in the center, and a small irradiation hole 7 is arranged in the fast neutron trap, and a higher fast neutron fluence rate can be obtained in the small irradiation hole 7; it is next to the seven-layer fuel assembly 2 There are several hexagonal beryllium components 5 arranged outside the annular area, and the beryllium components 5 are used as moderators and reflectors to form an inverted neutron trap; several large irr...

Embodiment 2

[0035] Such as figure 2 As shown, the high-fast neutron fluence rate core of the present invention includes a cobalt target 1, a seven-layer fuel assembly 2, a medium irradiation tunnel 3, a control rod assembly 4, a beryllium assembly 5, a large irradiation tunnel 6, a small irradiation tunnel According to the hole 7 and the four-layer fuel assembly 28; the seven-layer fuel assembly 2 and the four-layer fuel assembly 28 are all hexagonal casing fuel assemblies, and 39 seven-layer fuel assemblies 2 and three four-layer fuel assemblies 28 are annular and compact Arrangement, three seven-layer fuel assemblies 2 and three four-layer fuel assemblies 28 are arranged at intervals on the innermost ring, and a fast neutron trap is formed in the center of the ring area, and a small neutron trap is arranged in the fast neutron trap Irradiation tunnel 7, a higher fast neutron fluence rate can be obtained in the small irradiation tunnel 7; several hexagonal beryllium assemblies 5 are arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com