Anchor rod engineering stress simulation experimental device

A technology for simulating experimental devices and bolts, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., which can solve problems such as complex interaction relationships, failure to reflect the stress state of the bolt, and difficulty in simulating the stress of the bolt , to achieve the effect of low test cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

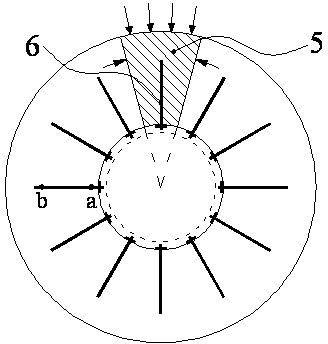

[0027] combined with figure 1 , the principle of using local test pieces in the present invention is that the stress, deformation and damage of the tunnel surrounding rock can be approximately regarded as an axisymmetric problem, therefore, a part of it can be taken, that is, the trapezoidal test piece 5 and the anchor rod described in the present invention Test piece 6 can reflect the properties of the surrounding rock as a whole. Compared with the full-section experimental device, the present invention can carry out large-scale experimental research.

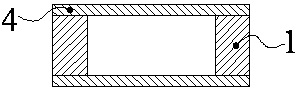

[0028] combined with figure 2 and 3 , a force simulation experiment device for bolt engineering, comprising a U-shaped groove 1, a triangular prism pad 2, a loading pad 3, a side baffle 4, a trapezoidal test piece 5 and a bolt test piece 6.

[0029] The U-shaped groove 1 is an integral structure, including a bottom plate and two side walls, and the lower surface of the bottom plate is in contact with the loading device of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com