Energy-saving dual-purpose furnace end using alcohol-based fuel

A technology of alcohol-based fuel and burner, which is applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of flame propagation speed, reaction speed, combustion temperature and combustion intensity, etc. high efficiency, high combustion efficiency, and sufficient gas combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

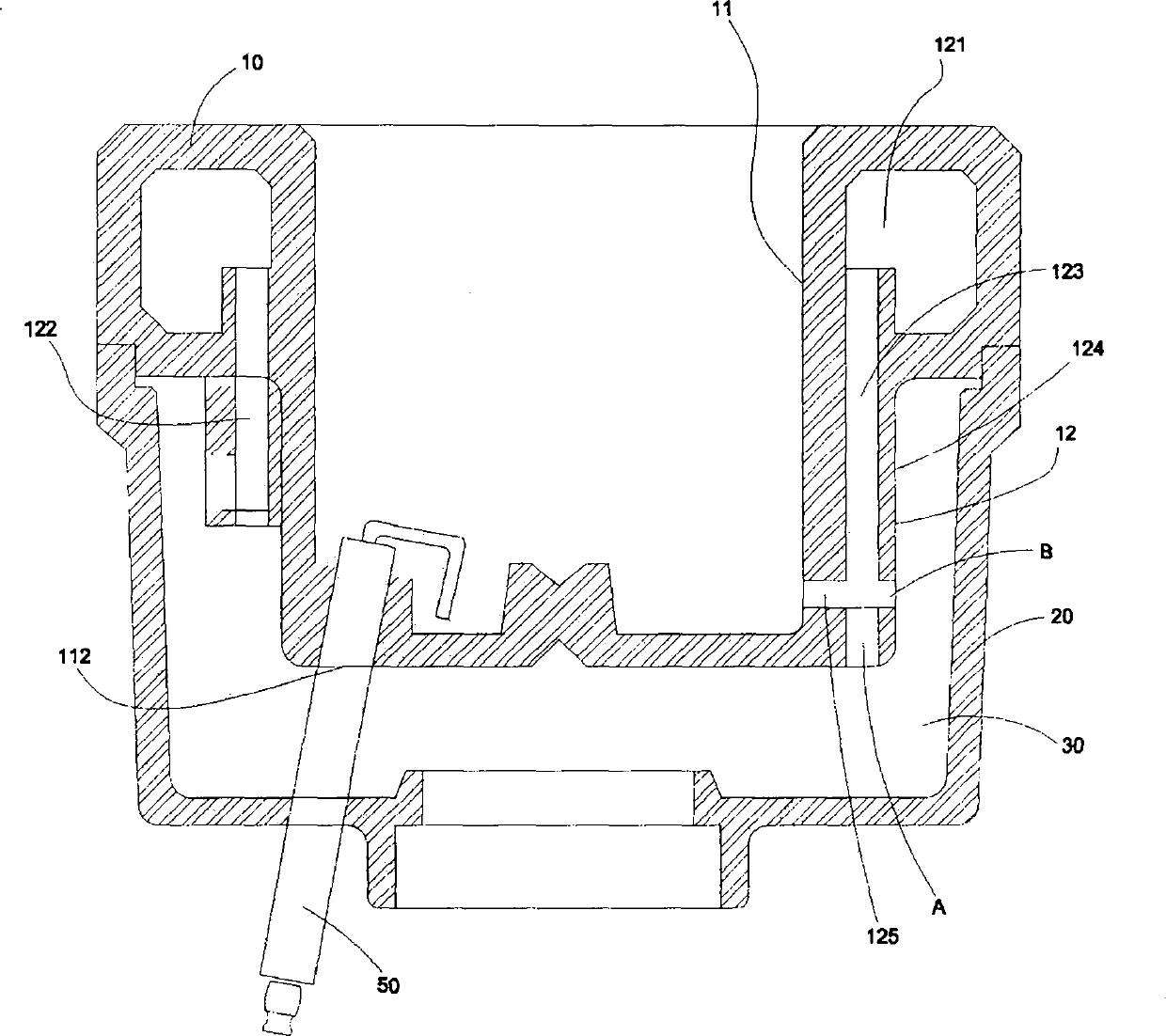

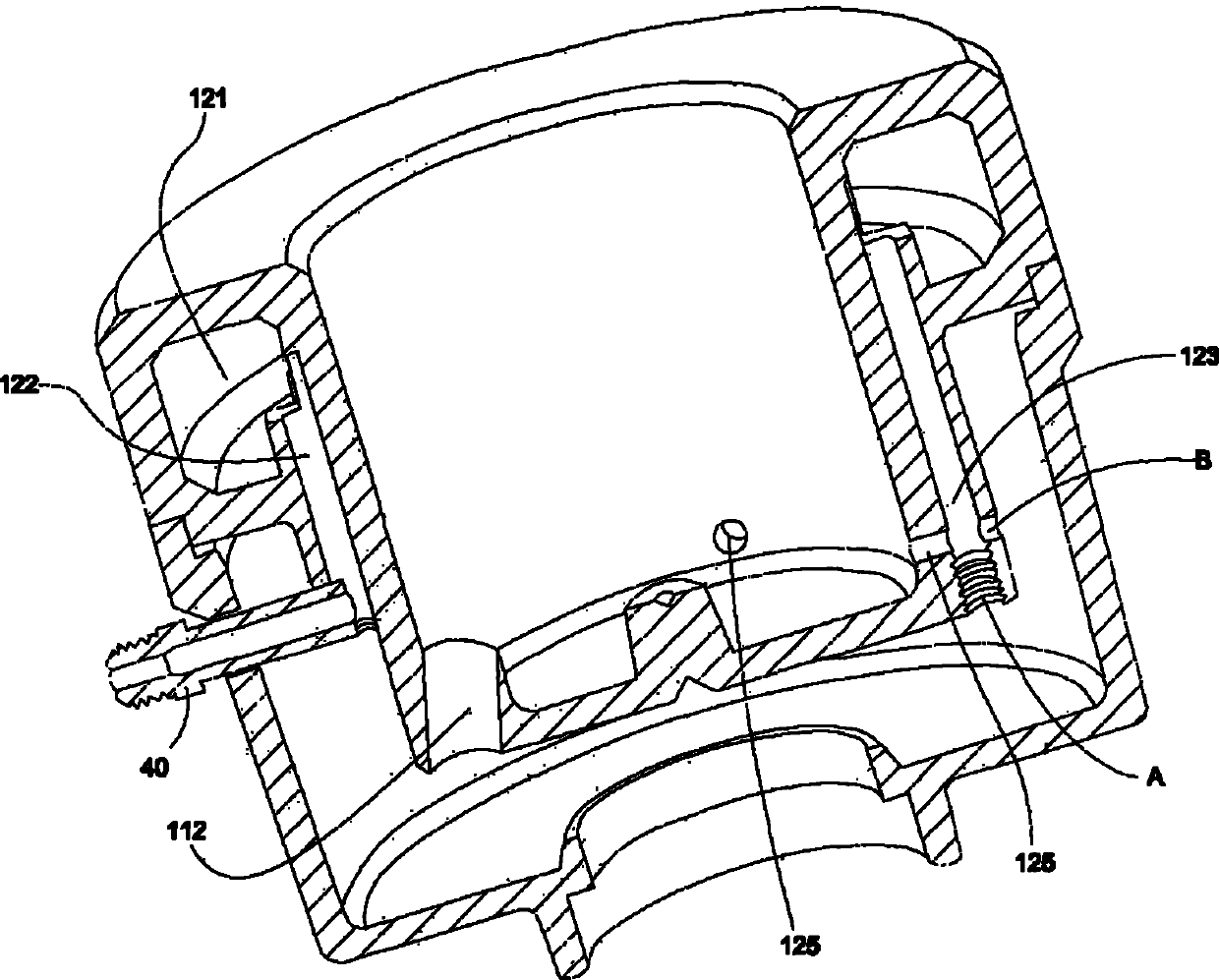

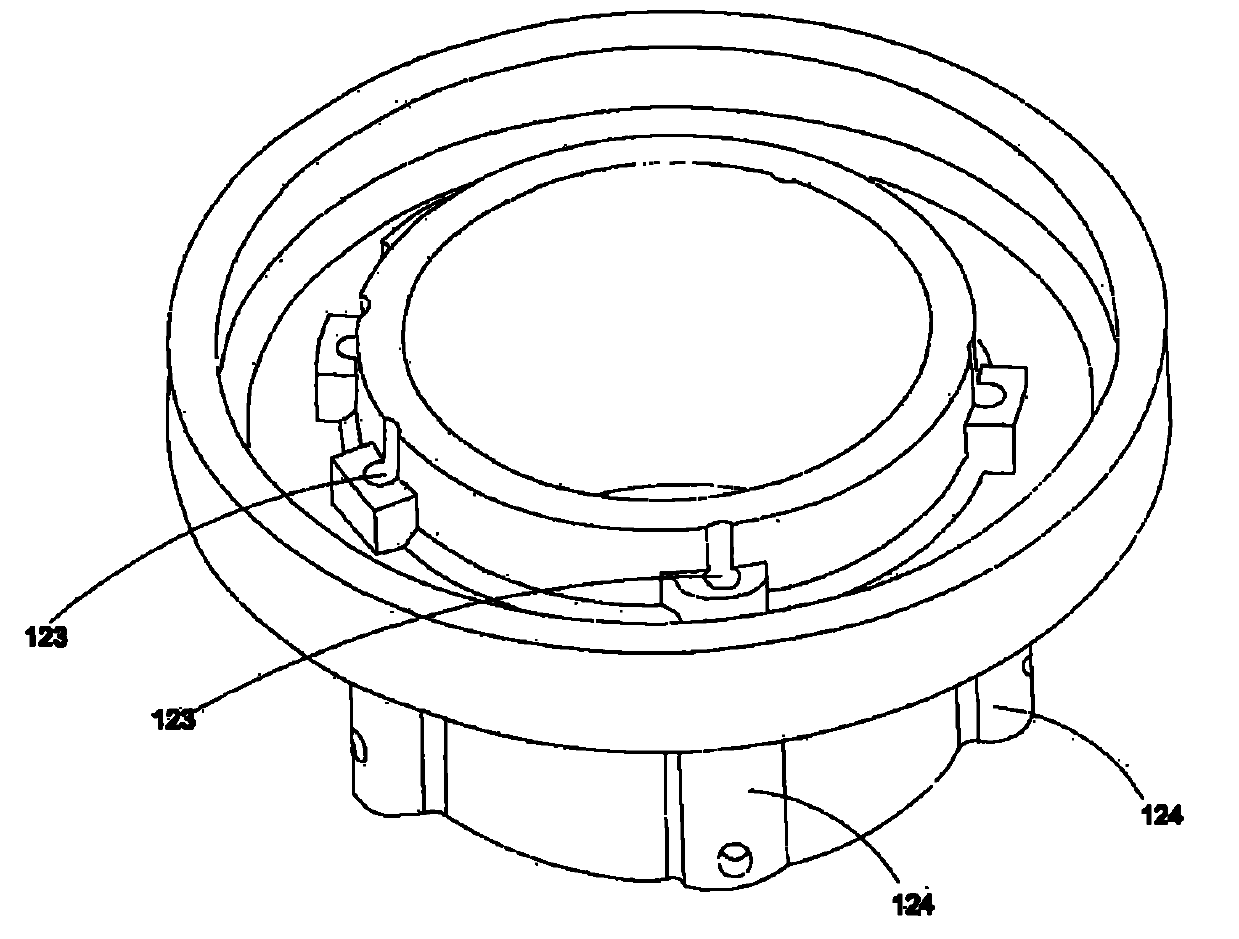

[0014] Such as Figure 1 to Figure 3 Shown is a preferred specific implementation example of the present invention, an energy-saving dual-purpose burner using alcohol-based fuel, including a burner 10 and a furnace bottom 20, wherein the burner 10 has an inner surface 11 and an outer surface 12. A combustion cavity 111 is formed around the inner surface 11. A closed preheating cavity 121 for fuel preheating is provided on the outer surface 12. After the fuel is burned in the combustion cavity 111, the heat passes through the combustion When the cavity wall and burner surface of the cavity 111 burn, heat energy is transferred to the preheating cavity 121 to heat the fuel entering the preheating cavity 121. The bottom 12 is the fuel burning area and is used to place the burner (Fig. not shown in the middle), the preheating chamber 121 is provided with an intake passage 122 for fuel to enter the preheating chamber 121, and the preheating chamber 121 is also provided with a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com