Heavy oil reservoir natural gas huff-and-puff oil production process system and oil production method

A heavy oil reservoir and process system technology, which is applied to the natural gas huff and puff recovery process system and oil recovery field of heavy oil reservoirs, can solve the problems of complex process and operation process, expensive operation cost, and large energy consumption, and achieve simple process flow, The effect of low cost and low energy consumption in oil extraction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to disclose the purpose, technical means and technical effects of the present invention more completely and clearly, the following is a detailed description, and please refer to the accompanying drawings and component numbers.

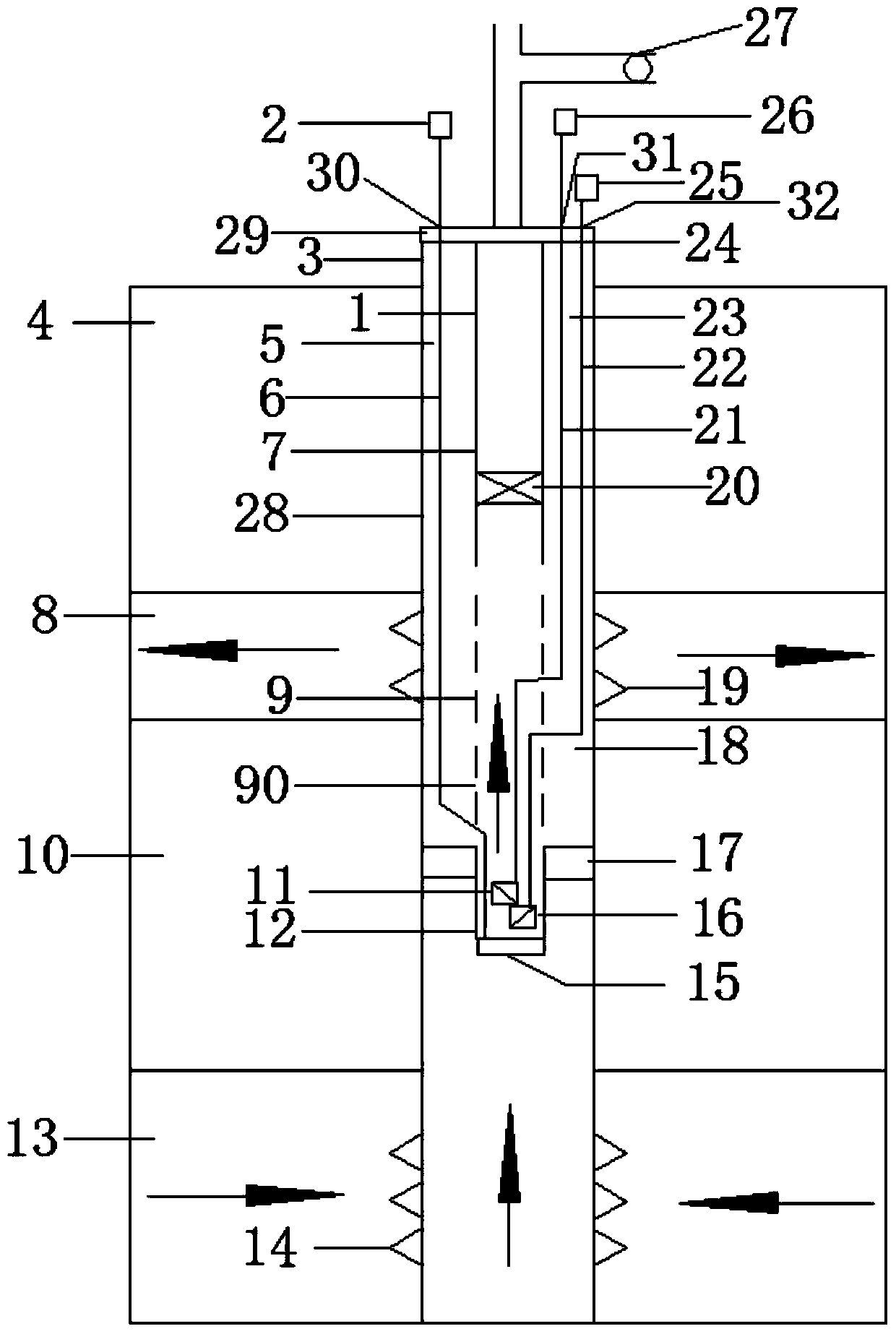

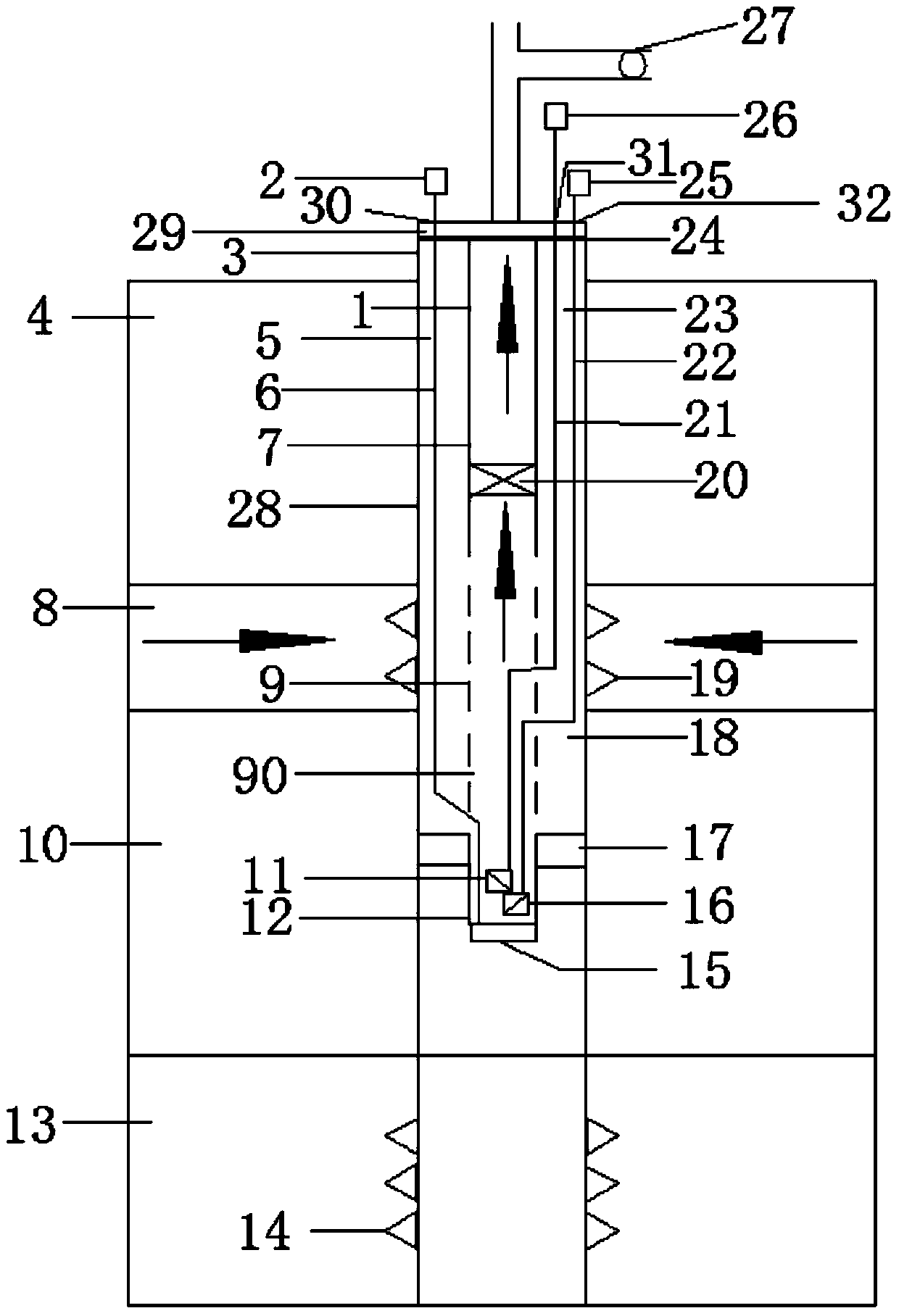

[0029] see figure 1 , first introduce the oil recovery process system of the present invention.

[0030] A natural gas huff and puff production process system for heavy oil reservoirs. A set of production string 1 is lowered into the wellbore 5. The production string 1 is sequentially connected with a first oil pipe 7, an oil well pump 20, and an eye pipe from top to bottom. 9. The packer 17 and the second tubing 12; the wellbore 5 has perforation sections at the positions corresponding to the oil layer 8 and the natural gas layer 13, and each perforation section has a plurality of blastholes 19 (or 14); The length of 9 is determined by the material strength of the eye pipe 9, the productivity of the natural gas layer 13, and the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com