Microbial powder, infant yoghourt and preparation method thereof

A technology of microbial bacteria and infants, which is applied in the field of infant yogurt and its preparation and microbial powder, can solve the problem that yogurt is not suitable for infants and young children, and achieve the effects of stable product properties, delicate state, and reasonable fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

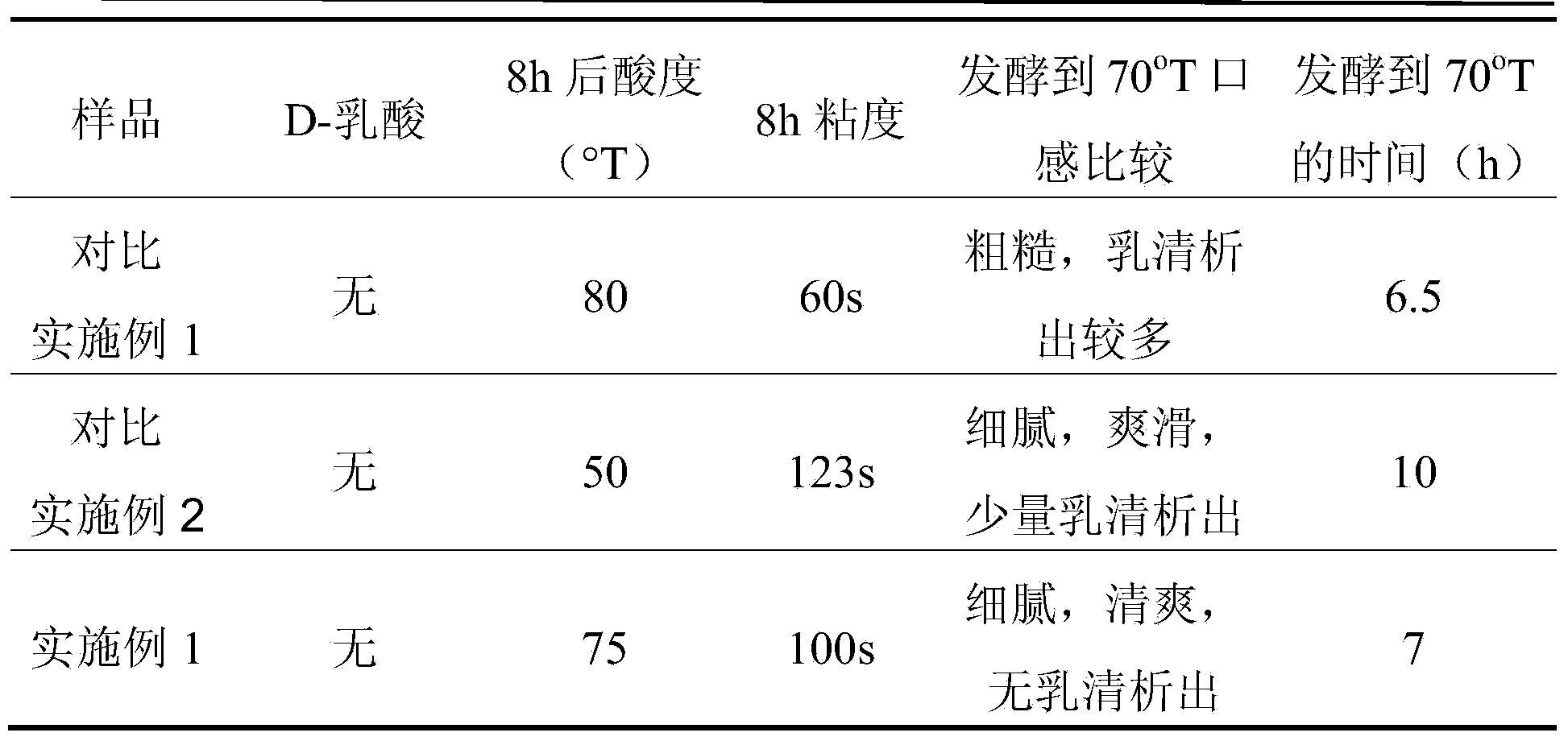

Embodiment 1

[0043]Preheat 250g of fresh skim milk to 45°C, add 63g of desalted whey powder with a whey protein content of 12%, add 70g of white sugar, stir for 20min, add 62g of cream (fat content 37%), mixed vegetable oil 8.8g, structured oil (OPO) 3.6g, stirred for 20min, homogenized for the first time, added water to 1000g, preheated to 55°C, and homogenized for the second time, homogenized pressure was 17MPa, sterilized at 90°C Cool to 42°C for 5 minutes, add microbial powder (Streptococcus thermophilus STI-13 and Streptococcus thermophilus Body-3 at a ratio of 1:1 according to the number of colony forming units (cfu)) 1×10 6 cfu / mL, fermented for 8 hours, cooled to 23°C, and filled.

Embodiment 2

[0045] Preheat 300g of fresh skim milk to 55°C, add 30g of whey protein powder with a whey protein content of 34%, 65g of white sugar, stir for 30min, add 55g of cream (fat content of 37%), 10g of mixed vegetable oil, and structured oil (OPO) 6g, stir for 28min, perform the first homogenization, add water to 1000g, preheat to 65°C, perform the second homogenization, the homogenization pressure is 20MPa, sterilize at 90°C for 5min, cool to 42°C , add microbial powder (Streptococcus thermophilus (Streptococcus thermophilus) STI-13 and (Streptococcus thermophilus) Body-3, the ratio of colony forming units (cfu) is 1:4) 2×10 6 cfu / mL, ferment for about 7 hours, cool to 23°C, and fill.

Embodiment 3

[0047] Preheat 280g of fresh skim milk to 50°C, add 25g of whey protein powder with a whey protein content of 34%, 60g of white sugar, stir for 26min, add 48g of cream (fat content of 37%), 12g of mixed vegetable oil, and structured oil (OPO) 8g, stir for 25min, perform the first homogenization, add water to 1000g, preheat to 65°C, perform the second homogenization, the homogenization pressure is 20MPa, sterilize at 90°C for 5min, cool to 38°C , add microbial powder (Streptococcus thermophilus (Streptococcus thermophilus) STI-13 and (Streptococcus thermophilus) Body-3, the ratio of colony forming units (cfu) is 1:2) 1.5×10 6 cfu / mL, ferment for about 12 hours, cool to 23°C, and fill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com