Ammonia absorption device and method for preparing ultra-clean high-purity ammonium hydroxide

An ammonia absorption and ammonia absorber technology, which is applied in the field of high-purity ammonia water absorption devices, can solve the problems of inability to obtain ultra-clean high-purity ammonia water, etc., and achieves the effects of good application value, compact equipment structure and high output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

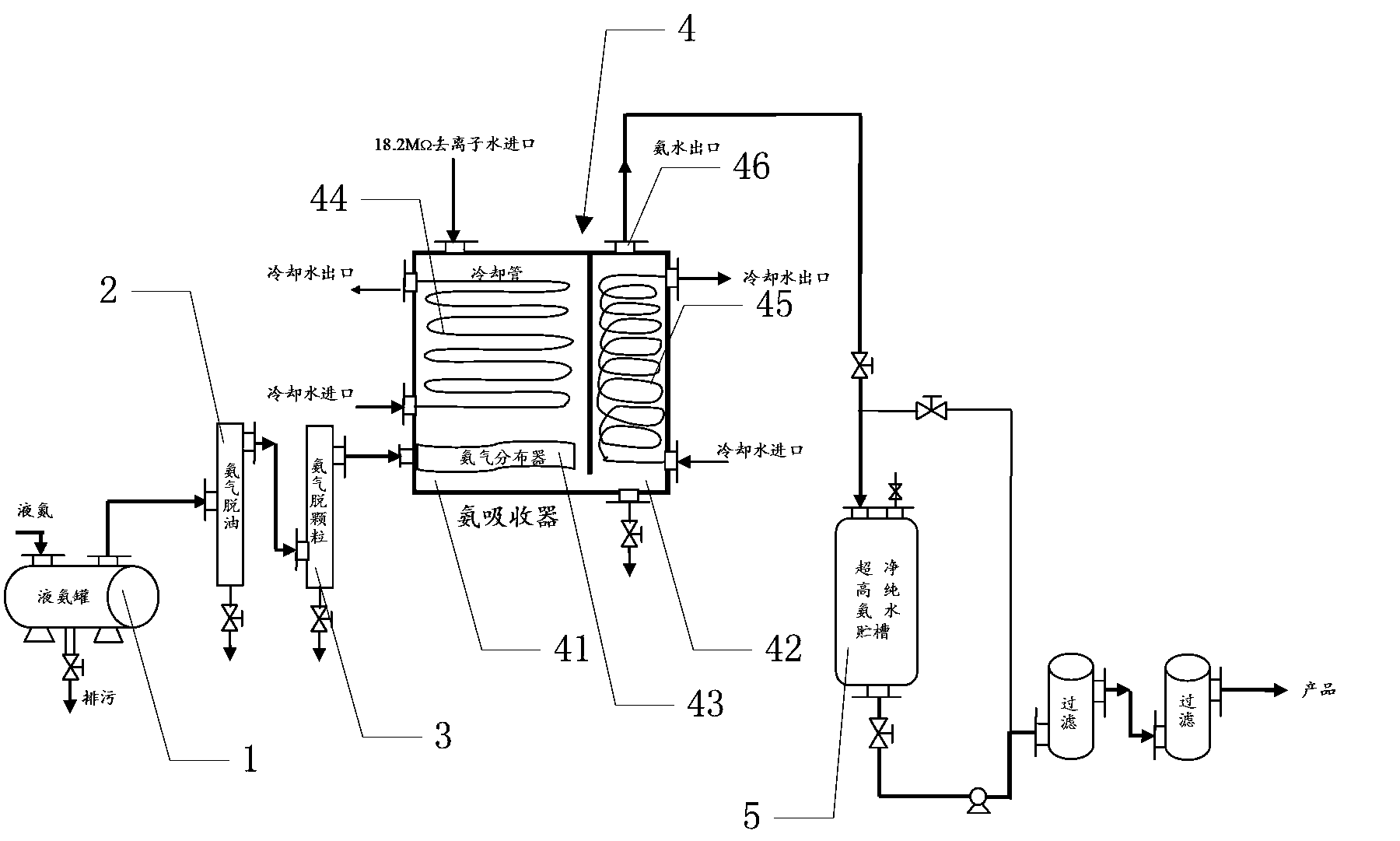

[0021] The ammonia absorption device constructed with high-purity materials includes a liquid ammonia tank 1, an ammonia gas deoiling device 2, an ammonia gas degranulation device 3, an ammonia absorber 4, and an ultra-clean and high-purity ammonia water storage tank 5 connected in sequence, wherein the liquid ammonia The outlet on the top of the ammonia tank 1 is connected to the inlet in the middle of the ammonia deoiling device 2, the outlet on the top of the ammonia deoiling device 2 is connected to the inlet in the middle of the ammonia degranulation device 3, and the outlet on the top of the ammonia degranulation device 3 Connected with the inlet of the ammonia gas distributor 43, the interior of the ammonia absorber 4 is divided into a first chamber 41 and a second chamber 42, the bottom of the first chamber 41 communicates with the bottom of the second chamber 42, the first The chamber 41 is provided with an ammonia distributor 43 and a first cooling pipe 44, the second...

Embodiment 2

[0027] The preparation method of ultra-clean and high-purity ammonia water includes the following specific steps: vaporizing liquid ammonia above first-class product; using an ammonia gas deoiling device 2 to carry out deoiling treatment on the vaporized ammonia gas to remove the oil in the ammonia gas ; Use the ammonia degranulation device 3 to remove the particles in the ammonia; the high-purity ammonia that has removed the particles is passed into the ammonia absorber, absorbed by deionized water, through the first cooling pipe 44 and the second cooling pipe 45 Cool to obtain ultra-clean and high-purity ammonia water.

[0028] The temperature of the ammonia water in the ammonia absorber 4 is 0-20° C., the pressure of the ammonia water in the ammonia absorber 4 is 0-0.1 MPa, and the ammonia water absorption time in the ammonia absorber 4 is 0.1-0.2 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com