Non-mezzanine bulk cement tanker tank for railroad

A technology for bulk cement and tanks, which is applied in packaging, transportation, packaging, containers, etc., can solve problems such as lowering the running quality of vehicles, cracking, and increasing the weight of tanks, so as to save time and convenience for maintenance and repair, eliminate invalid volume, The effect of simplifying the tank structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

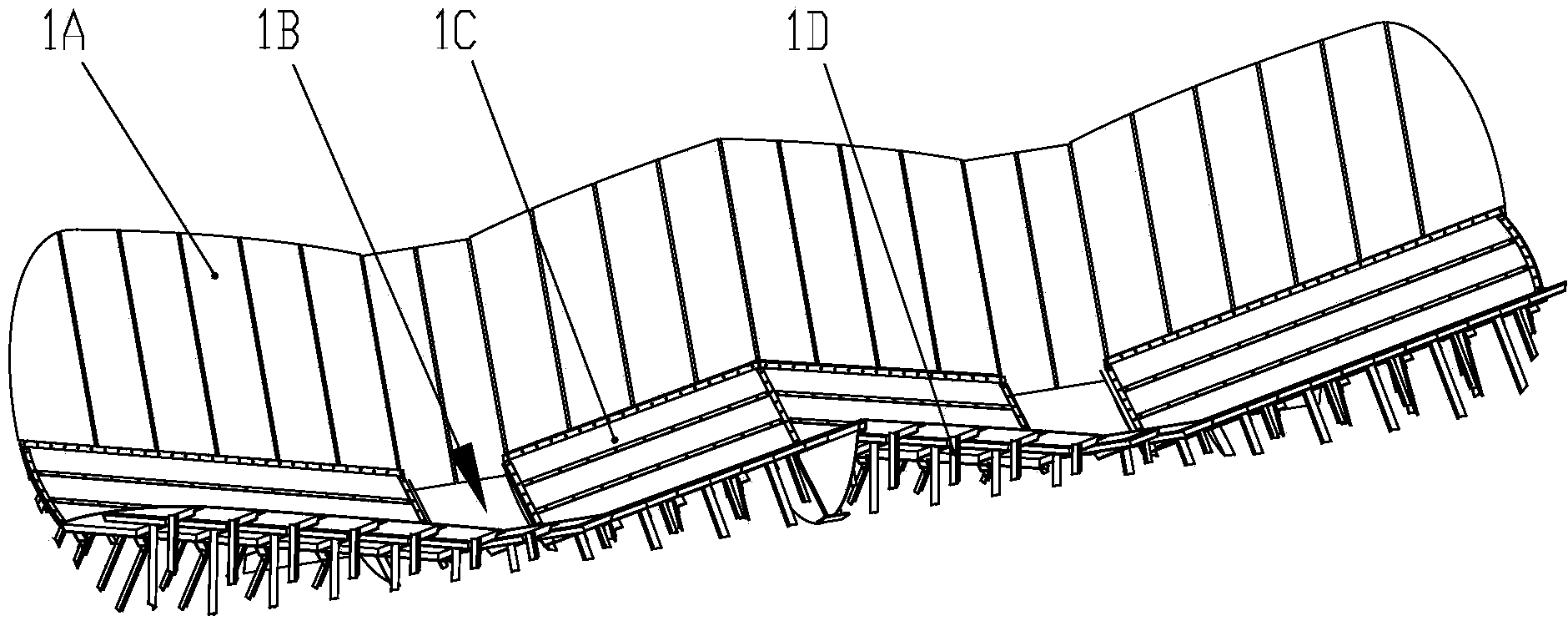

[0021] figure 1 It is a schematic diagram of the internal structure of the existing railway bulk cement tank car, and its structure has been introduced in the above-mentioned background technology, and will not be repeated here.

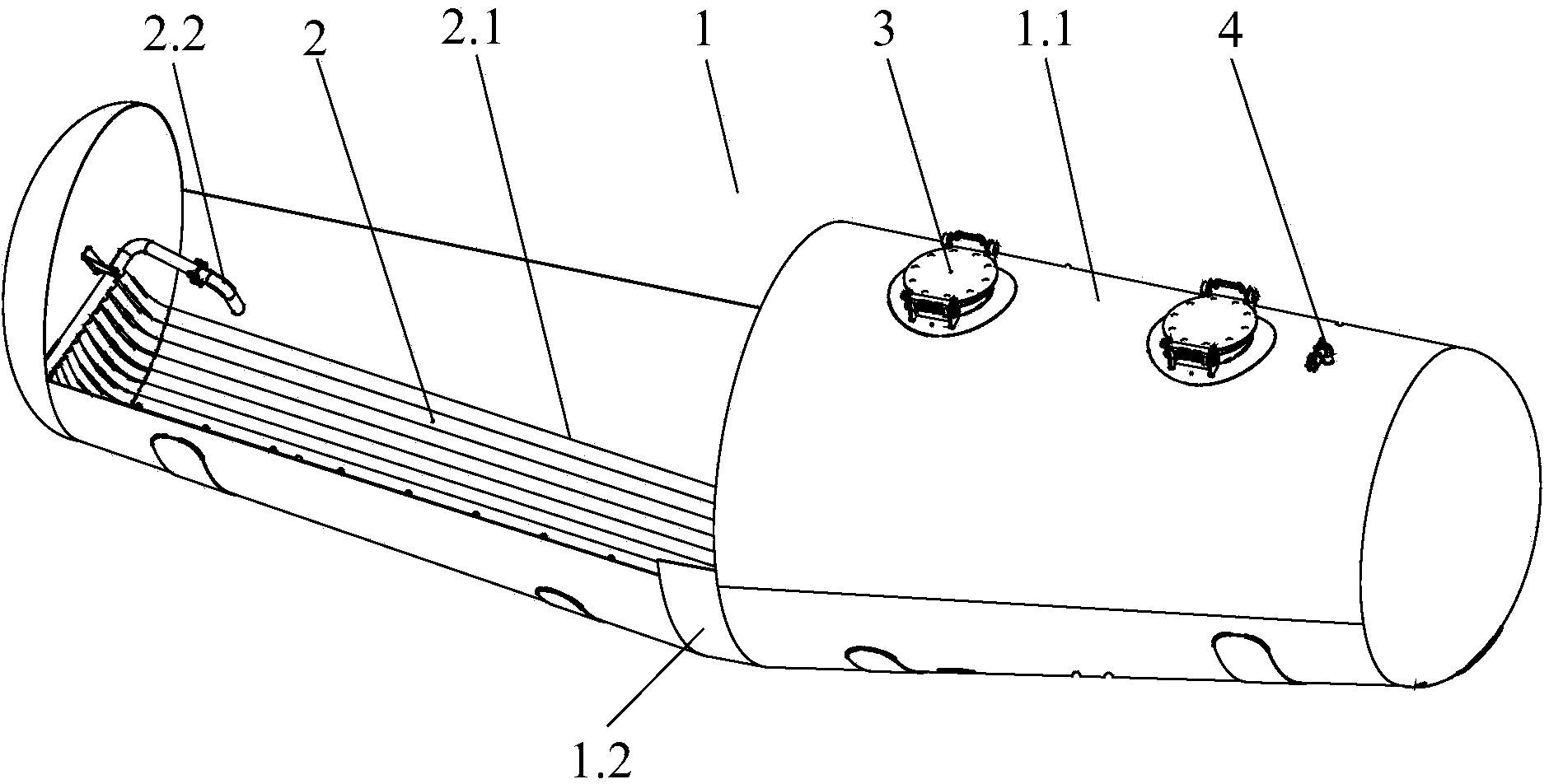

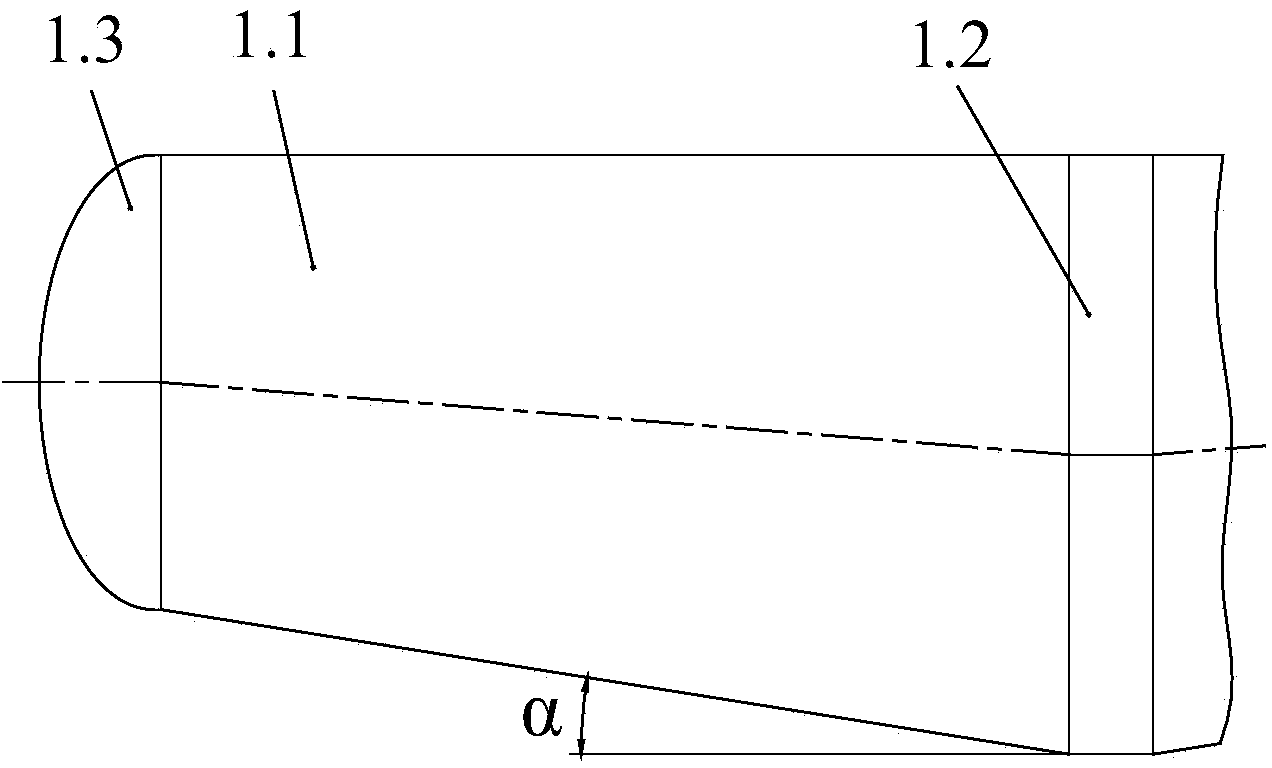

[0022] Figure 2-4 The tank body of the non-interlayer railway bulk cement tank car shown in , includes a horizontal tank body 1, which is a segmented composite structure, which has a middle short cylindrical section 1.2 for arranging the discharge port, and a middle short round The two ends of the cylinder section 1.2 are welded to the large-diameter ends of a pair of right-angle oblique conical cylinders 1.1, respectively, and the small-diameter ends of a pair of right-angle oblique conical cylinders 1.1 are respectively connected to a pair of tank heads 1.3 by welding; The self-weight of the body 1 lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com