Pulp board single knife cutting board paper machine

A paper unscrambling machine and board cutting technology, which is applied in stack changing and conveying, cutting of commercial pulp boards, pulp board single-knife cutting board paper unscrambling machine, paper unscrambling, and stacking fields, which can solve the problems of low production efficiency and labor intensity. Large size, large deviation of squareness, etc., to achieve good cutting and stacking effects, high degree of automation, and small deviation of squareness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Figure 1~Figure 11 An embodiment of the invention is shown.

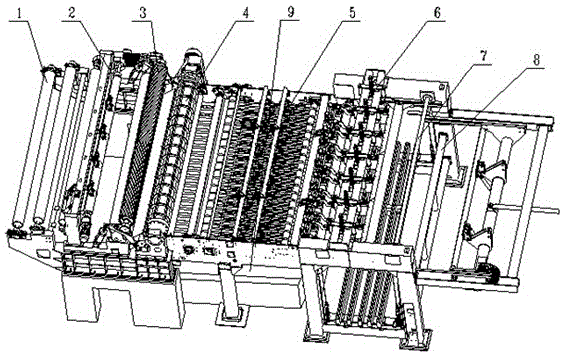

[0028] Such as figure 1Shown:: Pulp board single-knife cutting board paper machine includes 1-paper threading system, 2-longitudinal cutting system, 3-driving device, 4-cross cutting device, 5-conveyor system, 6-paper handling and stacking system , 7- Pallet changing system, 8- Main frame, 9- Broken paper conveyor. In addition, it also includes the necessary hydraulic system, pneumatic system and automatic control system. Except that the 9-broken paper conveyor is set under the 5-conveyor system and close to the pulp tank, the other systems are connected in sequence.

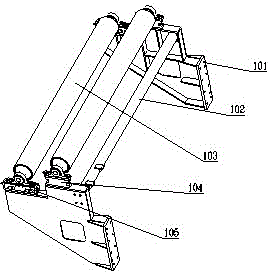

[0029] Such as figure 2 Shown: the threading part includes 101- side frame, 102- tie rod, 103- paper receiving roller, 104- tension detection device, 105- adjustment mechanism. An integral support composed of 101-side frame and 102-cross tie rod is the basis of load bearing. By adjusting the screw rod of the 105-adjustment mechanism, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com