Wave blocking device for explosive welding air impact waves

An air shock wave and explosion welding technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem of not effectively eliminating air shock waves, and achieve the effect of reducing the amount of smoke and dust, improving processing efficiency and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

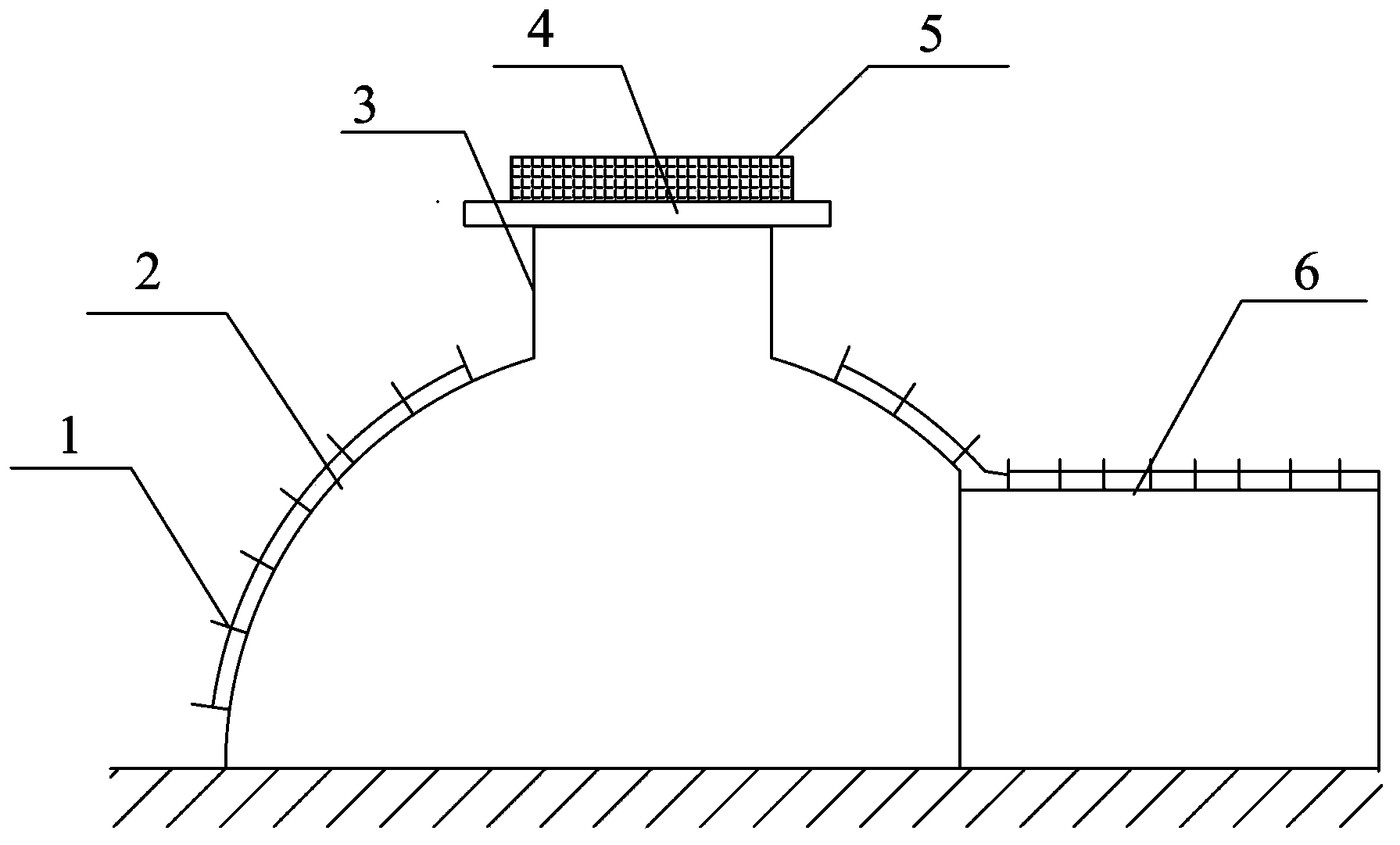

[0013] Such as figure 1 As shown, the wave blocking device for explosive welding air shock wave of the present invention adopts steel structure welding to manufacture a hemispherical container 2, the top of the container 2 is provided with a smoke exhaust port 3, and the front end of the container is provided with an access door through an access channel 6.

[0014] Container 2 is preferably 20mm structure 20# steel welded main body, which is strengthened by tension bars to make the structure have mechanical stability and mechanical strength (marker 1 in the figure is a rib plate). The entrance and exit adopt arch lengthening and cross-shaped arch reinforcement structure. The whole container is fixed and strengthened with backfill soil after construction. During the explosive welding process, after the explosively processed plate enters through the entrance and is installed, the smoke exhaust port 3 is covered with a steel frame 4 and covered with a water bag 5 above the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com