A Casting Process for Reducing Hardness Difference of Traction Sheave Rope Groove Surface

A casting process and traction sheave technology, which is applied in the field of casting technology to reduce the hardness difference of the rope groove surface of the traction sheave, can solve the problems of inconsistent solidification process, large temperature distribution difference in the position of the rope groove surface, difference in hardness, etc., and achieve temperature difference. Small, reduce the hardness difference, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

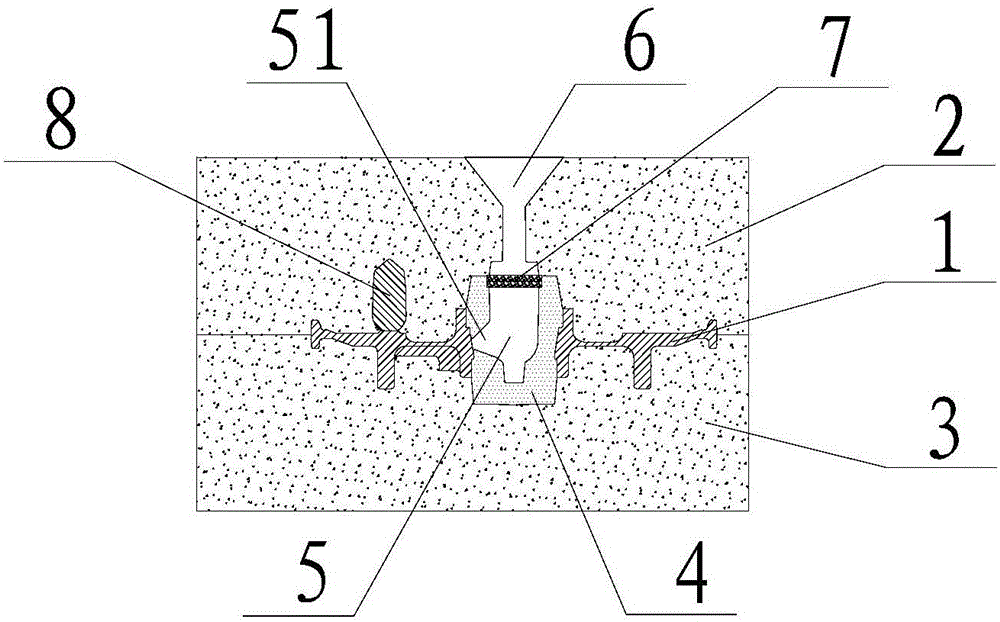

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

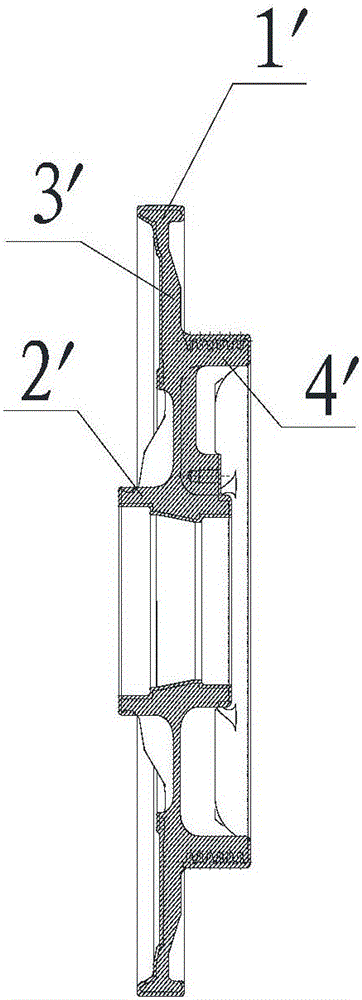

[0022] Using the casting process of the present invention to reduce the hardness difference of the rope groove surface of the traction sheave, such as figure 1 The traction sheave shown comprises the following steps:

[0023] (a) Make the upper sand box: fix the mold with the same size and shape as the traction wheel on the formwork, heat the mold to 30~50°C and spray a release agent on its surface, then place the upper box and fill it with molding sand, 100~120N / cm 2 Mechanical compaction is carried out under pressure, and the mold can be put on the sand box;

[0024] (b) Make the lower sand box: turn the fixed mold 180°, repeat step (a) to get the lower sand box;

[0025] (c) Core making: install the core box matching the traction wheel on the core shooter, open the mold to clean the core box and spray the mold release agent, then clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com