Spindle Assembly Structure on Elephant Trunk Reel

A technology of assembly structure and wire take-up machine, which is applied in the field of spindle assembly structure, can solve problems such as prone to failure, increased complexity, and unfavorable work efficiency, and achieve the effects of reducing failure rate, facilitating processing, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings.

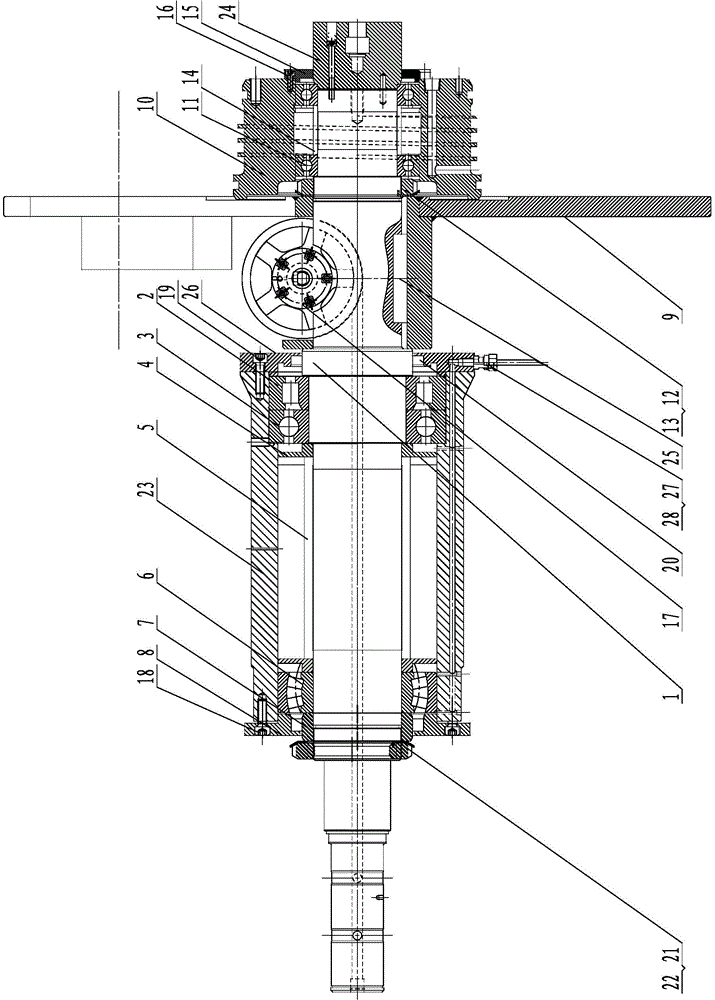

[0015] Such as figure 1 As shown: the main shaft assembly structure on the elephant trunk type wire take-up machine includes main shaft 1, roller bearing 2, first deep groove ball bearing 3, oil retaining ring 4, bearing spacer 5, self-aligning bearing 6, steel ring 7 , rear bearing cover 8, rotary plate 9, drum liner 10, second deep groove ball bearing 11, first stop washer 12, first round nut 13, bearing retaining ring 14, drum bearing cover 15, first Screw 16, main shaft guide wheel 17, second screw 18, third screw 19, skeleton oil seal 20, second round nut 21, second stop washer 22, main shaft sleeve 23, rotary joint 24, flat key 25, front bearing Cover 26, ferrule joint 27, copper pipe 28, etc.

[0016] Such as figure 1 Shown, the present invention comprises main shaft 1, and the center of main shaft 1 is provided with the middle hole that allows steel wire to pass thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com