Preparation method of CeO2/AgBr composite microsphere visible-light-driven photocatalysts

A technology of composite microspheres and visible light, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of microsphere preparation and photocatalytic performance that have not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Take 70 mL of diethylene glycol in a round bottom flask, add 0.01 mol of cerium acetate, slowly raise the temperature to 90°C, keep it warm for 8 hours, then add 0.00025 mol of silver nitrate, and continue the reaction for 0.5 hours. It is then washed, filtered, and vacuum dried. Then the dried powder was added to 3mL saturated bromine water, reacted for 1h, and finally filtered, washed, and dried to obtain CeO 2 / AgBr composite microsphere material. The X-ray powder diffraction experiment was carried out on the obtained sample, and its morphology and structure were observed under a transmission electron microscope.

[0018] According to the CeO that the process parameter of embodiment 1 makes 2 / AgBr composite microspheres visible photocatalyst XRD patterns such as figure 1 shown. There is obvious CeO in the map 2 , The characteristic diffraction peak of AgBr.

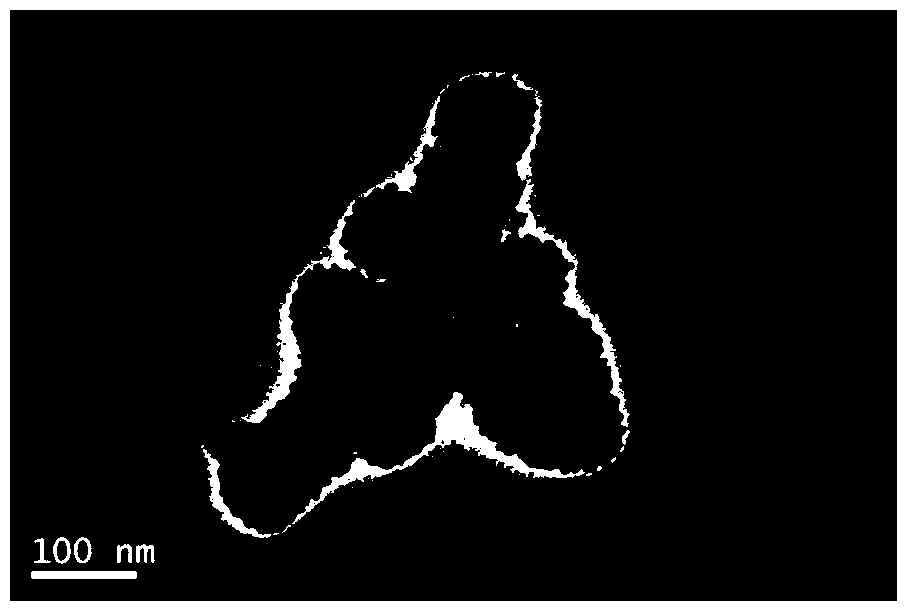

[0019] CeO 2 / AgBr composite microsphere visible photocatalyst sample TEM such as figure...

Embodiment 2

[0020] Example 2: Take 50mL of ethylene glycol in a round bottom flask, add 0.01mol of cerium acetate, slowly raise the temperature to 100°C, keep it warm for 5h, then add 0.0001mol of silver nitrate, and continue the reaction for 0.5h. It is then washed, filtered, and vacuum dried. Add the dried powder to 1 mL of saturated bromine water, react for 1 h, filter, wash, and dry to obtain CeO 2 / AgBr composite microsphere material. Subsequent detection was as in Example 1.

Embodiment 3

[0021] Example 3: Take 90 mL of ethylene glycol in a round-bottomed flask, add 0.01 mol of cerium acetate, slowly raise the temperature to 100° C., keep it warm for 8 hours, then add 0.0003 mol of silver nitrate, and continue the reaction for 1 hour. It is then washed, filtered, and vacuum dried. Then the dried powder was added to 5mL saturated bromine water, reacted for 1h, and finally filtered, washed, and dried to obtain CeO 2 / AgBr composite microsphere material. Subsequent detection was as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com