Rotational-flow type dust removing and desulfurization device

A desulfurization device, swirling flow technology, applied in the field of swirling dust removal and desulfurization devices, can solve the problems of unreasonable structure, short equipment life, high maintenance cost, etc., and achieve the effect of no maintenance, low cost and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

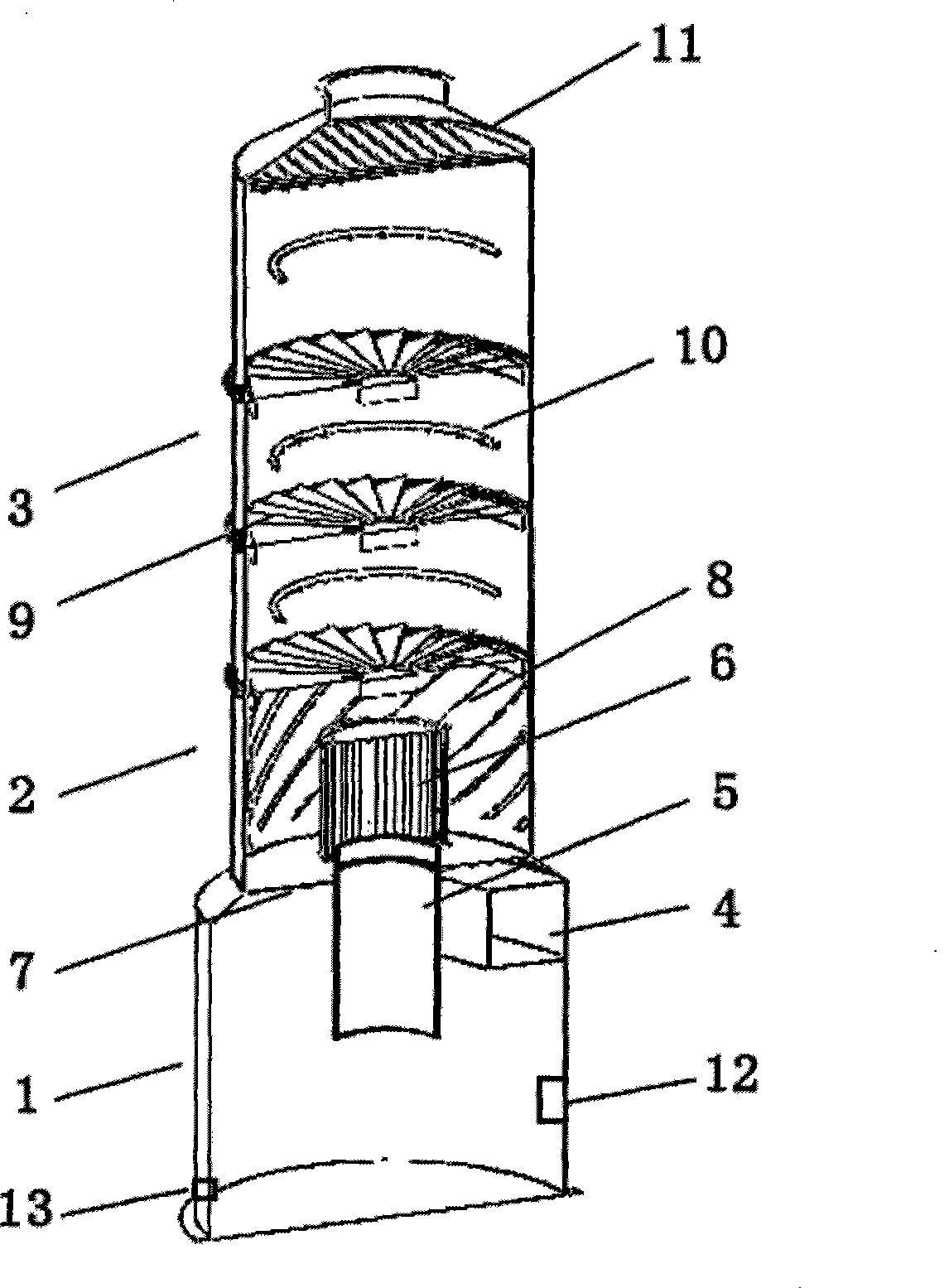

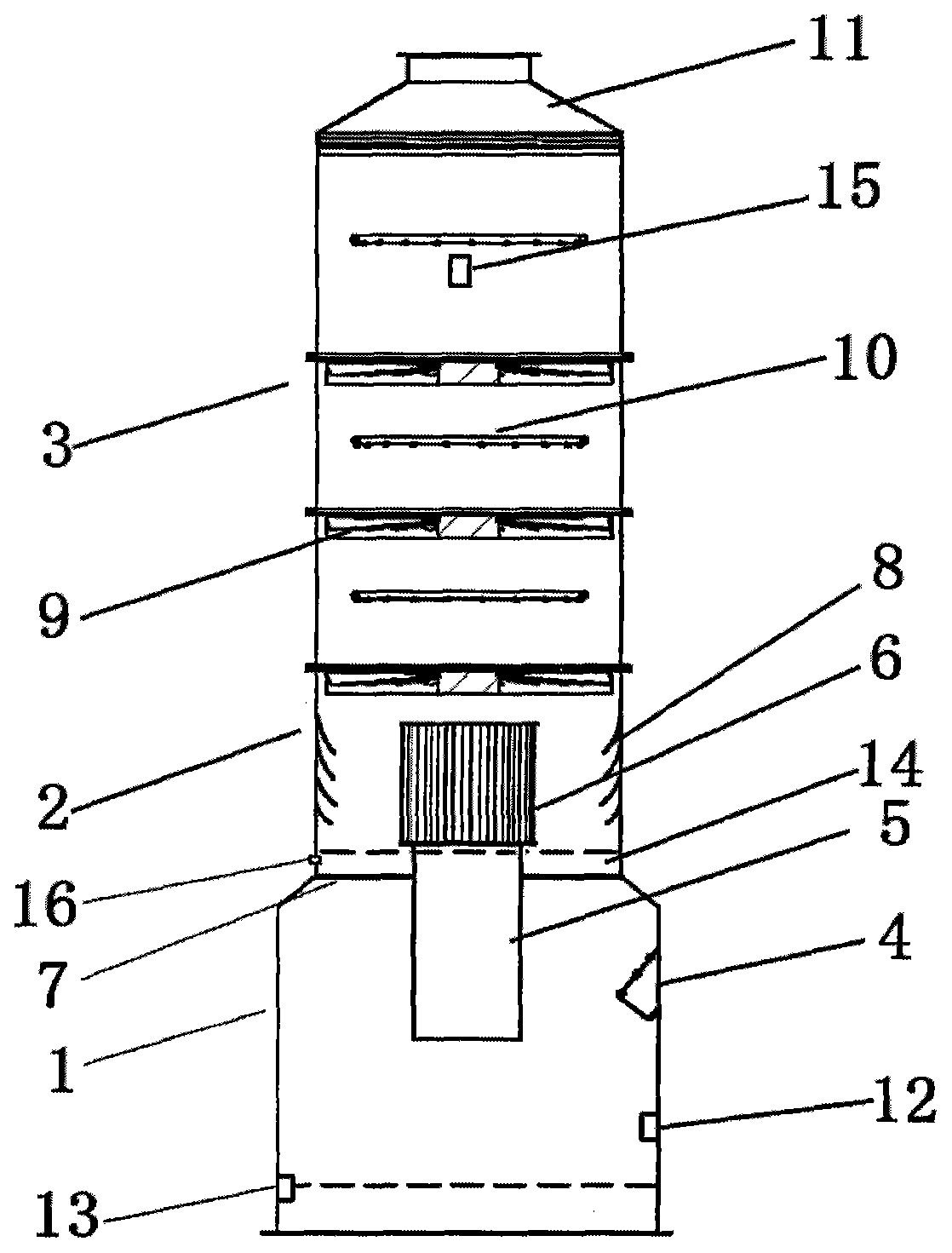

[0016] The cyclone dust removal and desulfurization device of the present invention will be further described in detail below with reference to the drawings and examples.

[0017] Such as figure 1 with figure 2 As shown, a cyclone type dust removal and desulfurization device includes a cylinder body, which is divided into a first chamber 1, a second chamber 2 and a third chamber 3 from bottom to top, and the first chamber 1 and the second chamber 2 A partition plate 7 is arranged between them; an air inlet 4 is arranged on the side wall of the first chamber, and the air inlet 4 and the cylinder wall form a certain angle and are arranged obliquely downward; the walls around the air inlet 4 are provided with water spray pipes; the first chamber 1. An air duct 5 is provided in the central area, and the air duct 5 is fixed on the isolation plate 7, and runs through the first chamber 1 and the second chamber 2; The device 6 is located in the second chamber 2; the inner side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com