Integrated type system for cooling, dewatering and demisting flue gas through ammonia desulphurization

An ammonia-based desulfurization and integrated technology, applied in the field of integrated systems, can solve problems such as blockage and collapse of demisters, and liquid droplets carried by outlet flue gas, so as to prolong the maintenance cycle, reduce process water loss, and reduce secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0008] see Attachment.

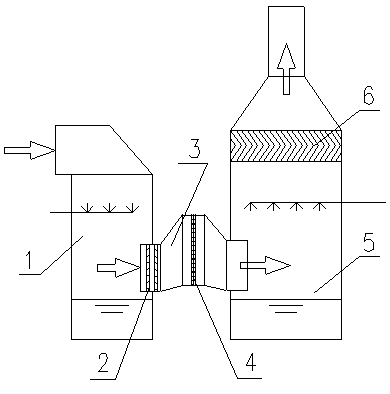

[0009] The integrated system for ammonia desulfurization flue gas cooling, water and mist removal consists of a concentration tower 1, an absorption tower 5, a connecting flue 3, a primary water removal device 2, a secondary mist removal device 4 and an outlet demister 6. The two ends of the connecting flue 3 are respectively connected to the concentration tower 1 and the absorption tower 5, and the first-level water removal and air distribution device 2 and the second-level demisting device 4 are arranged in the connecting flue, and the first-level water removal and air distribution device 2 is located between the concentration tower 1 and the absorption tower 5. Connecting the flue, at the joint of 3, the secondary defogging device 4 is located in the middle of the connecting flue 3, and the outlet demister 6 is set in the absorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com