Ventilating insole

A technology of insoles and leather pads, which is applied in the direction of insoles, footwear, clothing, etc., can solve the problems of shortened lifespan, dust clogging or water entering the shoes, and high price, so as to greatly increase the lifespan, eliminate discomfort, and smooth air intake Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

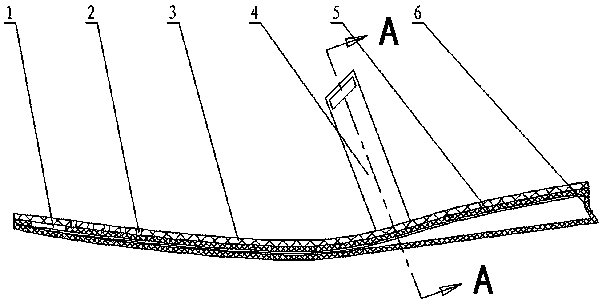

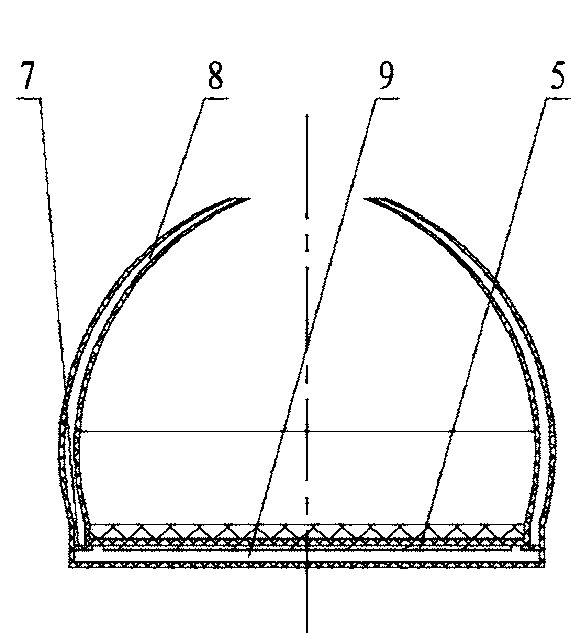

[0018] As shown in the figure, the ventilated insole is placed in the shoe, and the top of the airbag 6 in the ventilated insole is pasted with a leather pad 3, and a spring steel plate 5 is arranged in the airbag 6, and the front portion of the spring steel plate 5 is fixed with the wall of the airbag 6; The front end is provided with an air outlet 1, and many small holes 2 are also distributed in the position behind the air outlet 1 in the air bag 6 at the front end of the leather pad 3; the two sides of the air bag 6 are provided with an air intake band 4, and the air intake band 4 is pasted in the upper of the shoe, and its The air port is located under the tongue of the upper of the shoe, and the air channel 8 of the air intake belt 4 communicates with the inner cavity 9 of the air bag 6 through the one-way baffle valve 7; It opens automatically under the action of negative pressure, otherwise, when the air cavity is compressed, it closes against the inlet under the action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com