Garment-fitting lapel making method

A production method and technology of lapels, which are applied to tools for sewing clothes, clothing, uniforms, etc., can solve the problems of not being able to fit the lapels, affect the wearing effect of clothing, and not have a strong three-dimensional effect, and achieve a strong three-dimensional effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

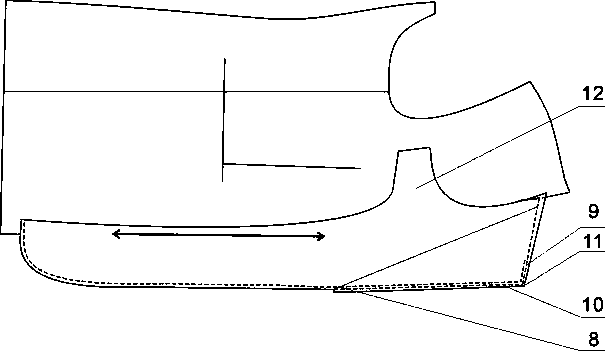

[0028] Embodiment 1 The method of three-button flat lapel clothing to make the lapels docile

[0029] as attached figure 1 As shown, step 1 covers the chest lining:

[0030] 1. Place the front end of the completed combined chest lining 1 at a distance of 1.0cm from the finished front door 2 to the barge line (3), with the front door 2 on top and the combined chest lining 1 on the bottom. The first stretching line is Use an interlock sewing machine to stretch from bottom to top parallel to chest dart 4, and loosen 0.3 on the front door within 2 cm from shoulder seam 5 down 14 cm.

[0031] 2. The second stretching line is stretched in parallel at a distance of 2cm from the barge line (3), and at the same time push the front door forward by 0.5cm.

[0032] 3. The third stretching line is stretched along the armhole at a distance of 4.5cm from the armhole (6). At the same time, pay attention to the straight direction of the yarn at the armhole of the front door.

[0033] 4. Pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com