Ridging and film mulching seeding machine

A seeder and film-covering technology, applied in the field of agricultural machinery, can solve the problems of the joint operation unit being blank, increasing the number of times the tractor presses the ground, increasing investment costs, etc., and achieve the effect of simple and compact structure of the unit, power saving and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

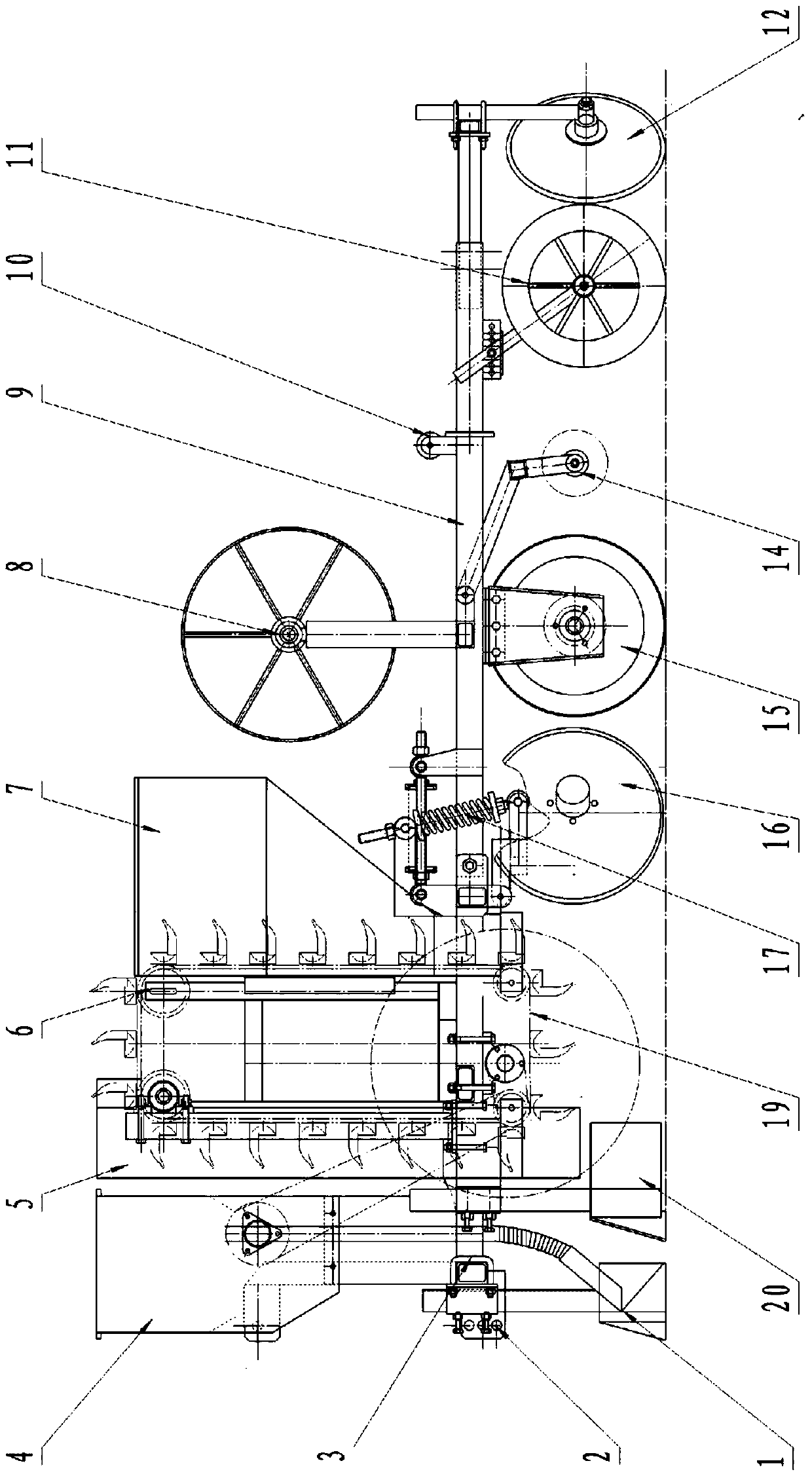

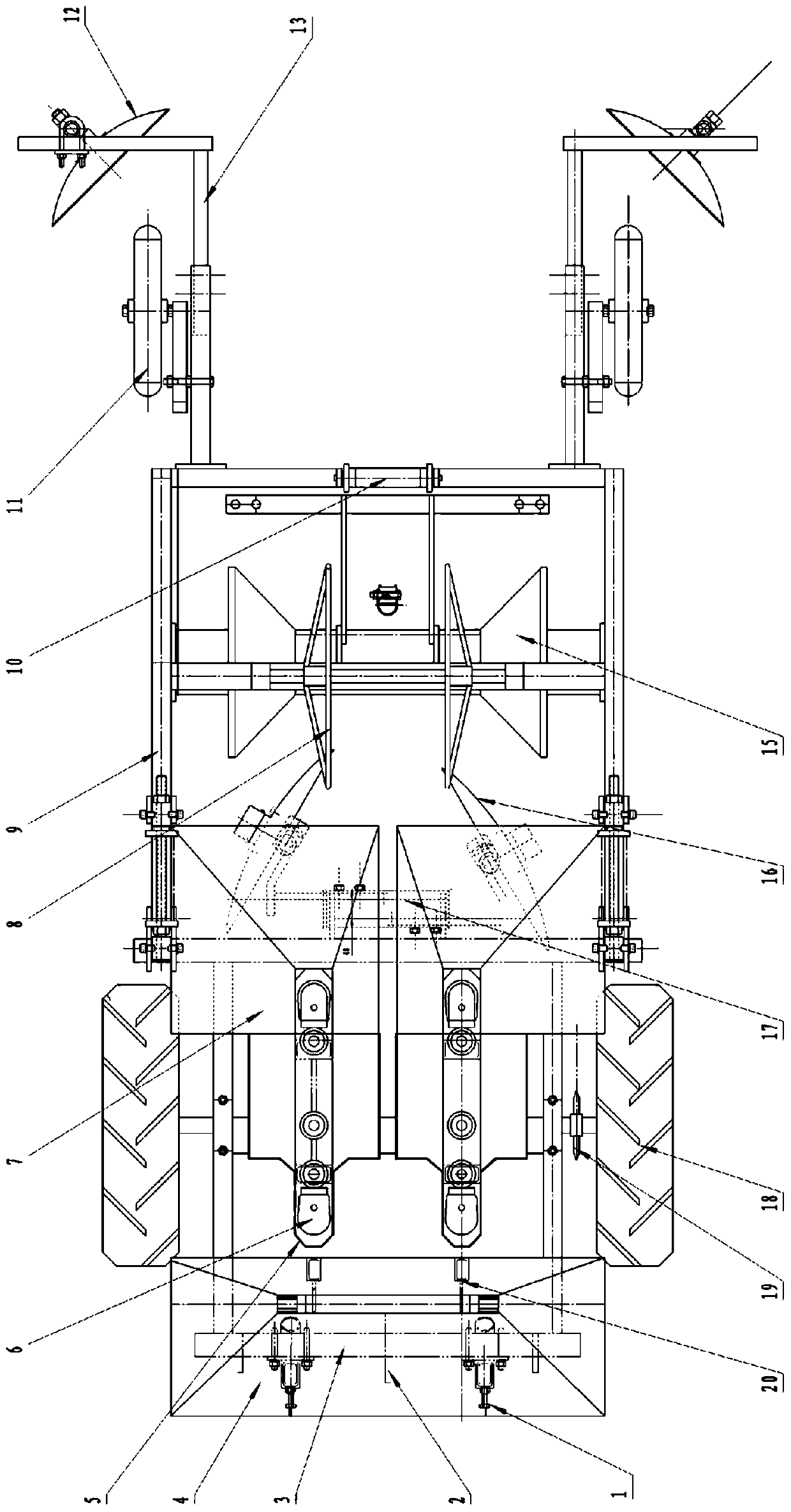

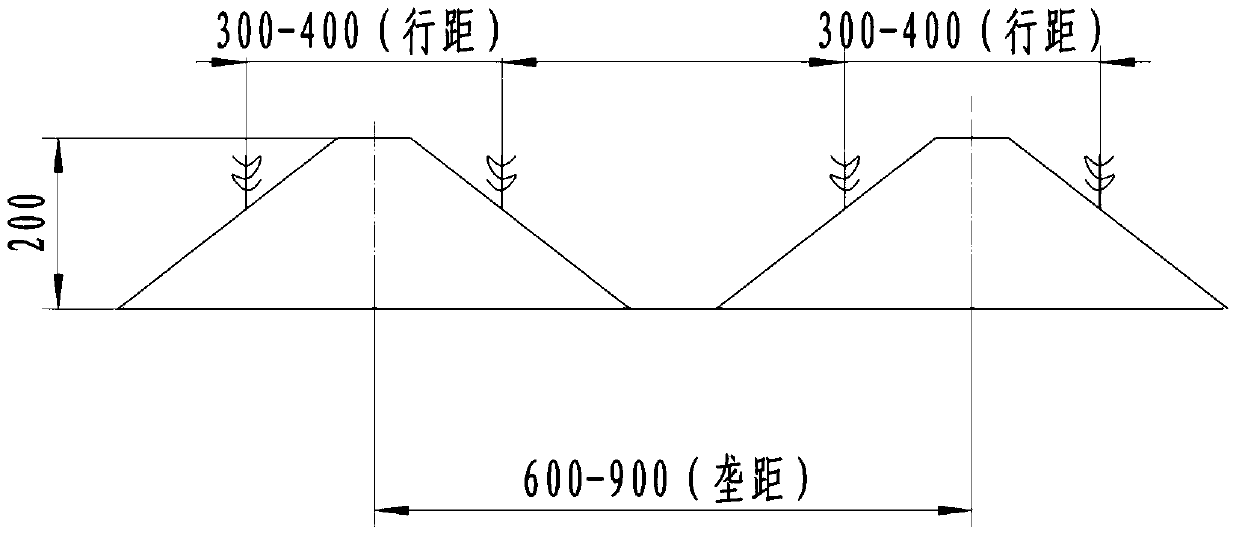

[0034] Such as figure 1 , figure 2 As shown, the ridge mulching planter consists of a fertilizing ditching shovel 1, a suspension frame 2, a front frame 3, a fertilizer box 4, a seeding pipe 5, a seed potato seeding mechanism 6, a seed potato box 7, and a drip irrigation pipe support 8. Rear frame 9, drip irrigation pipe guide pulley 10, film pressing wheel mechanism 11, disk covering mechanism 12, L-shaped telescopic frame 13, film roll support 14, ridge shaper 15, disk ridge mechanism 16, Ridging mechanism depth adjustment device 17, ground wheel 18, transmission mechanism 19, seed potato opener 20 are formed.

[0035] Wherein the front frame 3, the rear frame 9, and the L-type telescopic frame 13 are respectively placed in the front, middle end and rear of the ridge film-covering and seeding combined operation unit.

[0036] Fertilization ditching shovel 1, suspension frame 2, seed fertilizer box 4, seed tube 5, seed potato seeding mechanism 6, seed potato box 7, disc ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com