Prediction method of fatigue life of electromagnetic riveted joints

A fatigue life prediction, electromagnetic riveting technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of long time consumption and high cost, and achieve the effect of shortening time consumption and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

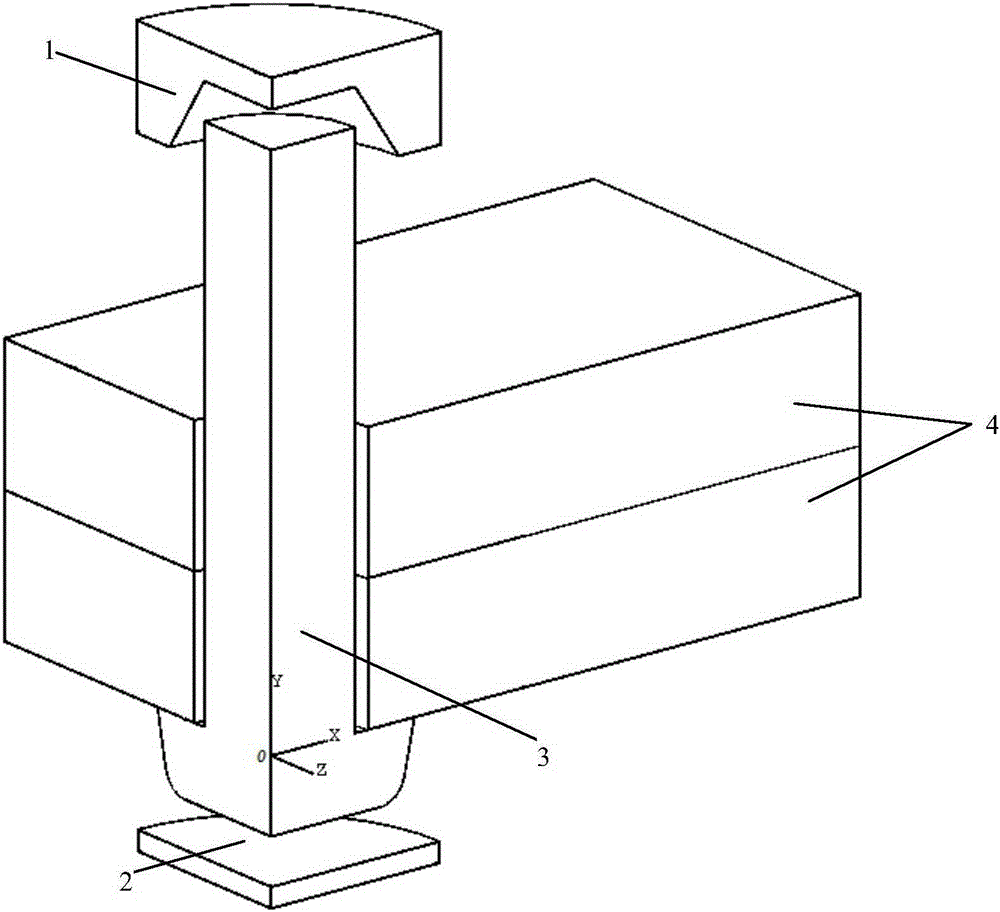

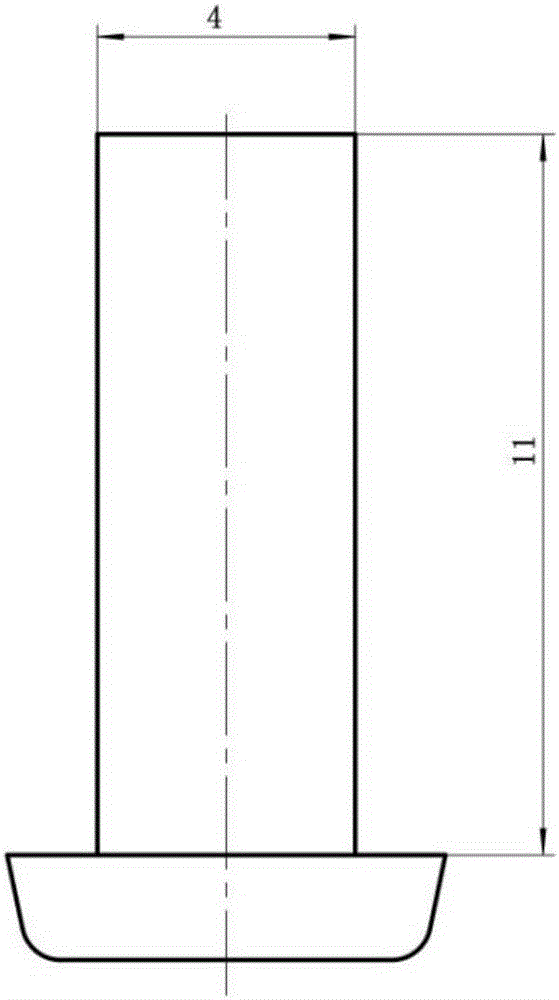

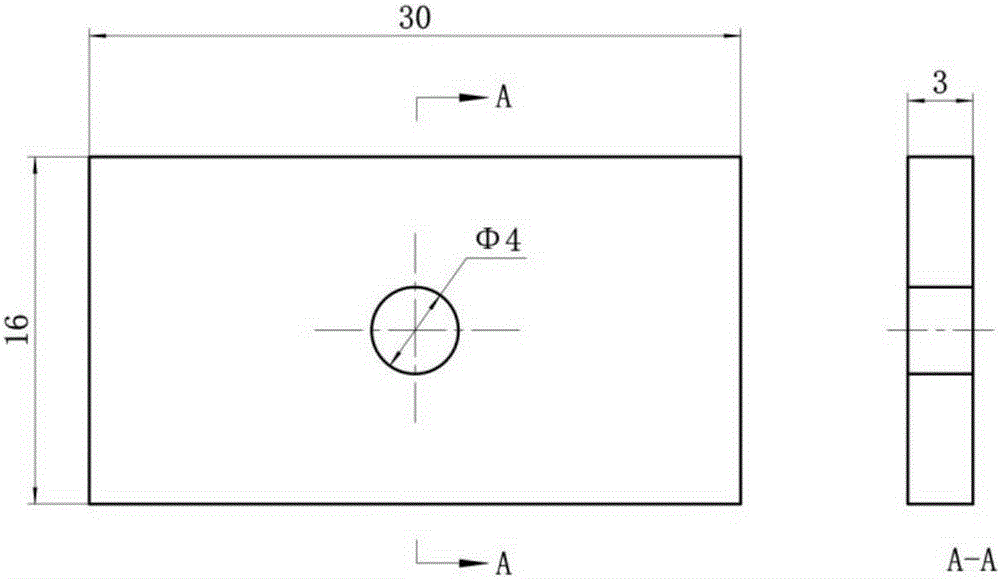

[0019] refer to Figure 1-5 . In order to overcome the problems of high test cost and long time consumption, and replace the current test method used to obtain the fatigue life of electromagnetic riveted structures, the present invention discloses a method for calculating the life of electromagnetic riveted joints by using the stress and strain results obtained by numerical simulation. This method uses the structural stress and strain obtained by numerical simulation as the input of the fatigue life model, so that the fatigue life of the electromagnetic riveted joint can be obtained through pure calculation. Compared with the test method, this method can significantly reduce the cost and time consumption of life acquisition.

[0020] According to one aspect of the present invention, the numerical simulation is performed by finite element simulation, and the finite element model is used to define a specific electromagnetic riveting process of the metal sandwich. The model inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com