Water-mist dust settling method implemented during blast excavation for large-scale underground project

A technology of underground engineering and water mist, which is applied in blasting, separation methods, chemical instruments and methods, etc., can solve problems such as difficulty in dissipating blasting dust, frequent blasting operations, and many excavation work faces, so as to ensure health and safety, implement Convenience, reduce the effect of blasting dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiments.

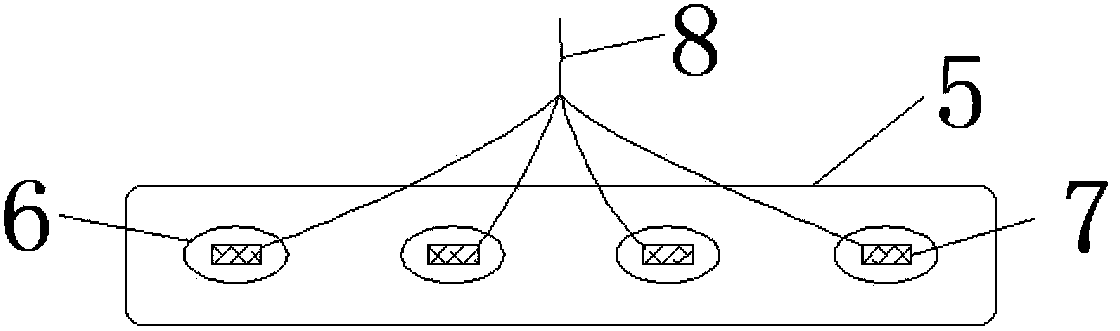

[0021] Figure 4 This is an initiation network diagram of an embodiment of the present dust reduction method.

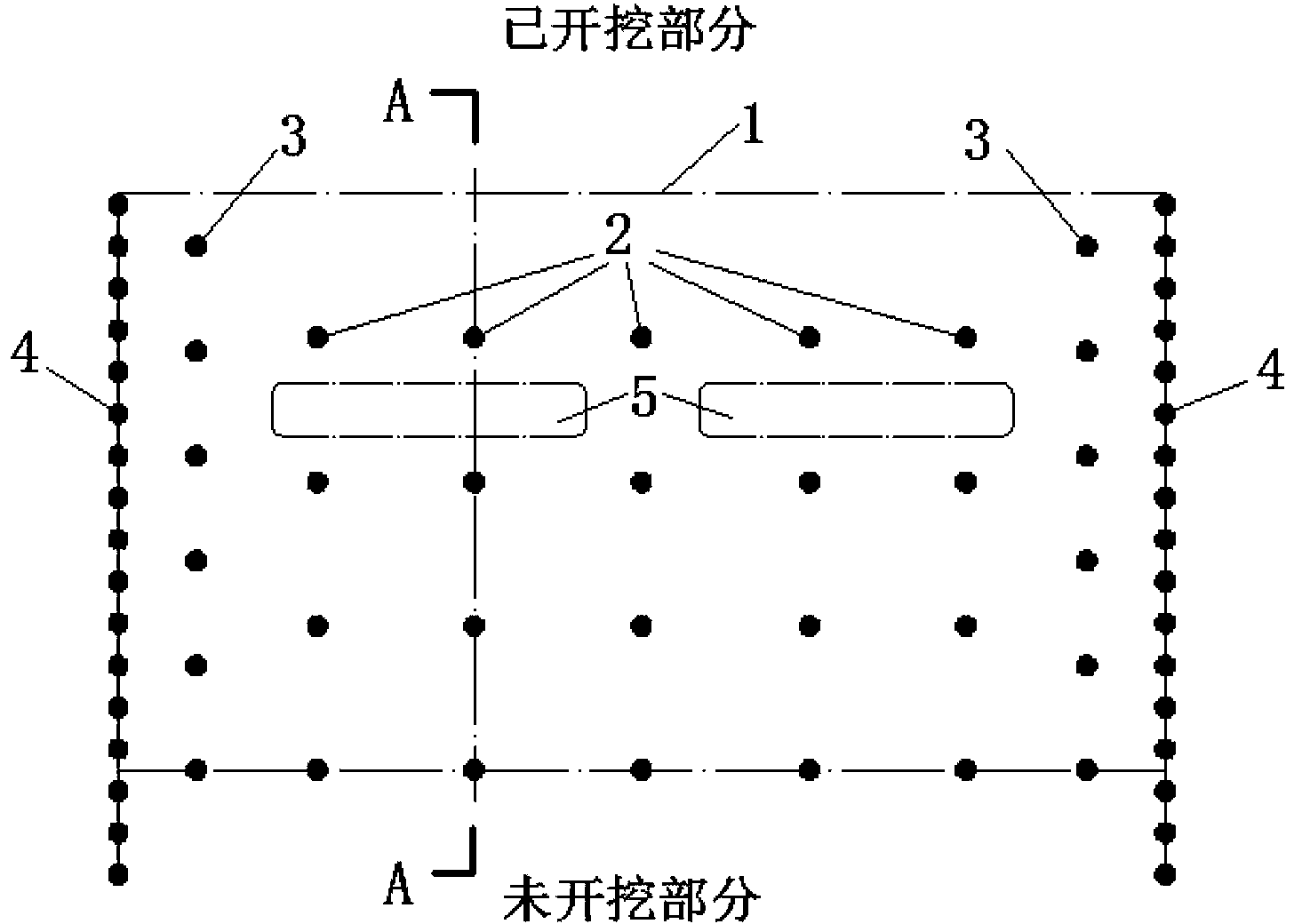

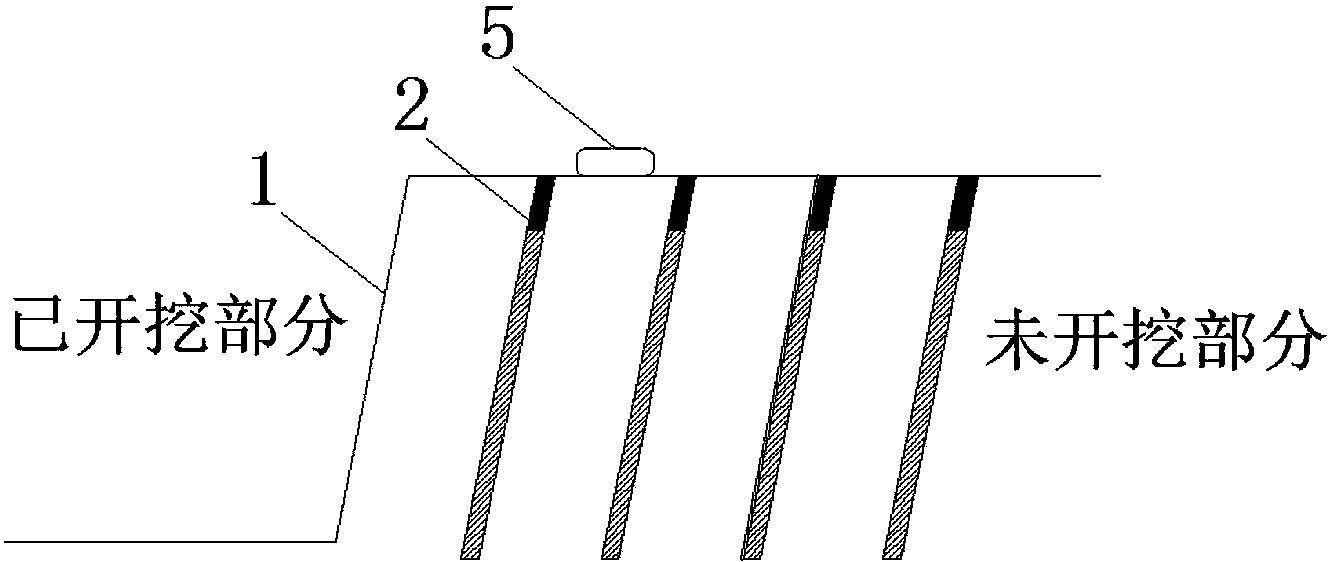

[0022] The underground cavern is fully excavated by deep-hole bench blasting. The cavern is 20m wide, 8m footage in a single excavation, 9.5m height of steps, four rows of main blastholes, 5 main blastholes in each row, excavation The contour surface is a pre-split blast hole. A buffer hole is set between the pre-split blast hole and the main blast hole. figure 1 , figure 2 Shown. According to the present invention, the following steps are carried out in sequence: In the drawings, 1-work surface (empty surface); 2-main blast hole; 3-buffer hole; 4-pre-split hole; 5-water bag; 6-emulsion explosive charge pack; 7-MS1 section of non-electric detonator; 8-section of detonator in the water bag; 9-namely power generation detonator; 10-MS15 section of non-electric detonator; 11- MS3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com