Two-post pressurizing furnace

A column type and furnace lining technology, which is applied in the field of heat treatment processing equipment, can solve the problems of limiting the life of the electric furnace, affecting the service life of the heating element, and falling off of the heating element, achieving the effect of good fixing effect, prolonging the life and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

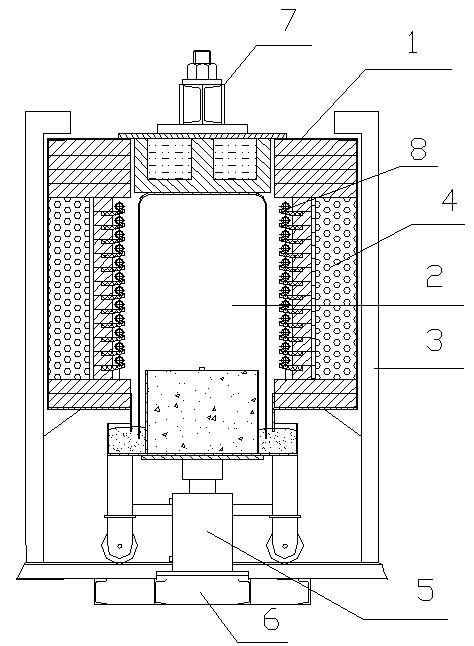

[0014] A two-column pressurized furnace provided in this embodiment includes a furnace body 1, a furnace chamber 2, a furnace lining 4, a guide column 3, a top cylinder 5 and a base 6, wherein the furnace lining 4 includes a brick layer and a refractory fiber layer, the two occupy half of the space, the brick layer is located on the side close to the furnace 2, the high temperature alloy wire is placed on the brick layer 2, the upper center of the furnace body 1 is welded with the lifting lug 7, and the guide column 3 Welded on both ends of the base 6.

[0015] This embodiment provides a two-column pressurized furnace. When working, the product is placed on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com