Air source heat pump water circulation heat exchange drying system

An air source heat pump and water circulation technology, applied in drying, drying machines, heating devices, etc., can solve the problems of large size and energy consumption, and achieve the effects of reducing humidity, uniform heating form, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment is an air source heat pump water circulation heat exchange drying system, its composition and connection relationship are as attached figure 1 shown.

[0021] The air source heat pump water circulation heat exchange system given in this embodiment includes a hot water circulation loop and a hot water heat exchange circulation loop, and also includes a cooling water circulation loop and a cold water condensation circulation loop, as shown in the attached figure 1 As shown, the hot water circulation loop includes a compressor 10, an evaporator 11, a throttle valve 12, a condenser 13, a hot water storage tank 14, and connecting pipes, and the hot water heat exchange circulation loop includes a hot water storage tank 14, Heating heat exchanger 15, hot water pipeline 16, circulating water pump 17; figure 1 As shown, the cooling water circulation loop includes a compressor 20, an evaporator 21, a throttle valve 22, a condenser 23, a cold water storage tank 24...

Embodiment 2

[0023] This embodiment is a practical air source heat pump water circulation heat exchange drying system, its composition and connection relationship are as attached figure 2 shown.

[0024] In this embodiment, the compressor, evaporator, throttle valve, and condenser in the heating water circulation loop are integrated into a hot water heat pump unit 101, and the compressor, evaporator, throttle valve, and condenser in the cooling water circulation loop are also integrated The device is integrated into a chilled water heat pump unit 103.

[0025] In this embodiment, the condenser of the cooling water heat pump unit 103 and the evaporator of the heating water heat pump unit 101 are sealed and confined in the same space by connecting the air guide device 102 in the form of a box body, so that the cooling water heat pump unit generates heat during operation. The heat energy is used again by the hot water heating heat pump unit in the hot water heating process, which improves t...

Embodiment 3

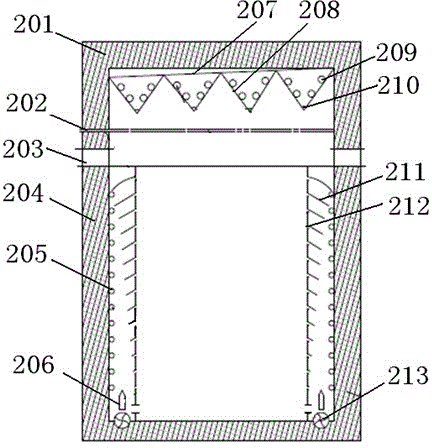

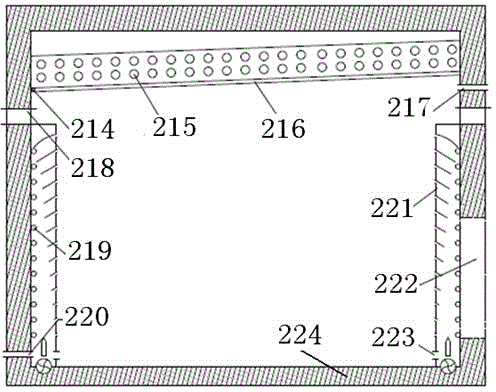

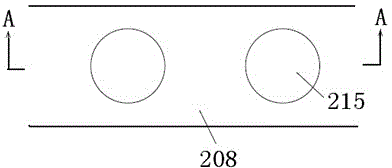

[0031] This embodiment gives a structural design example of a practical drying room, the transverse section of the structure is as attached image 3 , the longitudinal section of its structure is as attached Figure 4 shown.

[0032] In this embodiment, the drying room is composed of heat-insulating side wall 204, heat-insulating roof 201, and ground base insulation layer 224. A wall heat-resisting layer 203 is arranged between the heat-insulating side wall 204 and the heat-insulating roof 201, and the heat exchanger is heated. The capillary 205 is arranged along the facade of the thermal insulation side wall 204, and an upright turbulence plate 221 is set on the side of the capillary 205 towards the center of the drying room. Groove or through hole 212, and wind deflector 211 is arranged at the upper edge of each through groove or through hole 212, and the length of wind deflector 211 increases along with the rise of its level, at the bottom of drying room 1. A fan 213 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com