Negative pressure dual-stage leakage-free seal device

A sealing device, leak-free technology, applied in the components of the pumping device for elastic fluids, non-variable-capacity pumps, machines/engines, etc., can solve problems such as medium leakage, achieve good sealing effect, and ensure the sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

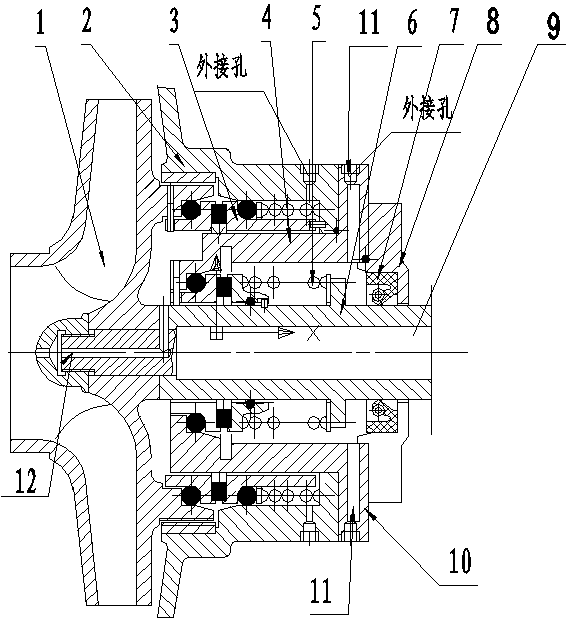

[0009] Such as figure 1 As shown, the present invention connects the impeller 1 at the front end of the main shaft 9, coaxially arranges the shaft sleeve 6 and the pump cover 2 outside the main shaft 1, and sets the isolation cavity cover 8 at the rear end of the pump cover 2, and the rear end of the shaft sleeve 6 passes through the Place it in the middle hole of the isolation cavity cover 8, and set the skeleton oil seal 7 between the isolation cavity cover 8 and the shaft sleeve 6.

[0010] A cylindrical spacer sleeve 4 is set between the shaft sleeve 6 and the pump cover 2, and an annular boss 10 is provided at the rear end of the spacer sleeve 4. The annular boss 10 is arranged between the pump cover 2 and the isolation cavity cover 8, Two radial through holes 11 are provided on the annular boss 10, and sealing rings are provided between the annular boss 10 and the pump cover 2, and between the annular boss 10 and the isolation cavity cover 8 respectively.

[0011] A sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com