Magnetic transmission piston-type valveless compressor

A magnetic drive, piston technology, applied in the field of compressors, can solve the problems of reduced efficiency, non-continuous discharge of compressed air, pulsation, etc., to achieve smooth operation, avoid vibration or sudden change in transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

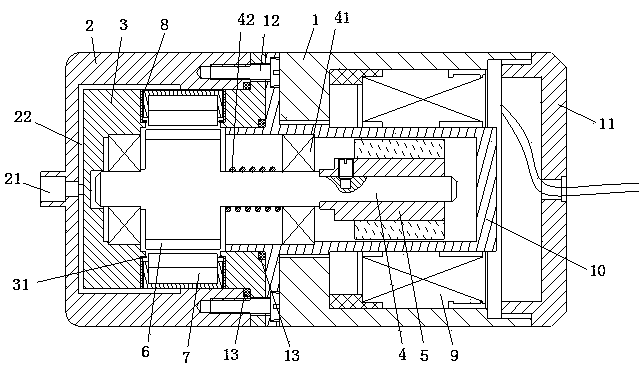

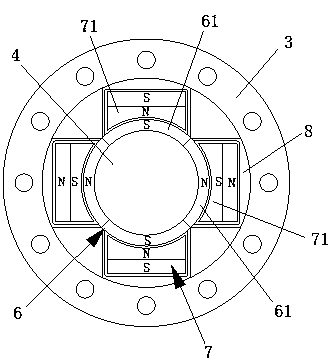

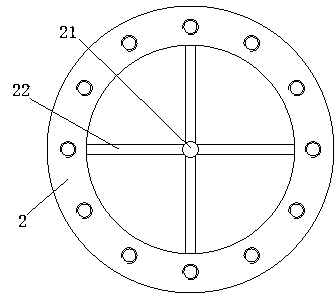

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] Such as Figure 1-Figure 3 A magnetic drive piston type valveless compressor shown includes a motor casing 1, the two ends of the motor casing 1 are respectively connected with a cylinder head 2 and a rear cover 11, the cylinder head 2 is provided with a cylinder liner 3, and the compressor also includes Crankshaft 4, one end of crankshaft 4 is coaxially provided with motor rotor 5 and this end is positioned at motor casing 1, and the other end of crankshaft 4 is coaxially provided with magnetic force rotor 6 and this end is positioned at cylinder liner 3, and also sets in cylinder liner 3 There is a magnetic piston 7 matched with the magnetic rotor 6, and the magnetic rotor 6 forms an adsorption or repulsion state with the magnetic piston 7 under the rotating force of the crankshaft 4, so that the magnetic piston 7 is in a state of continuous reciprocating motion, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com