Fully automatic lead filling machine

An operating machine, fully automatic technology, applied in gas flame welding equipment, coating, metal material coating process and other directions, can solve the problems of uneven work quality, affecting the production progress of the factory, long lead enamel work cycle, etc. Improve work efficiency, ensure physical health, and accurately control the quality of lead enamel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific embodiments.

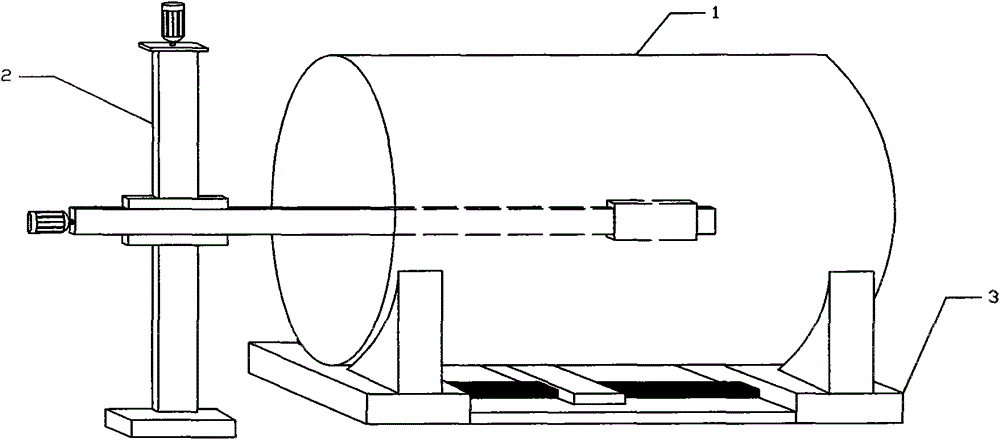

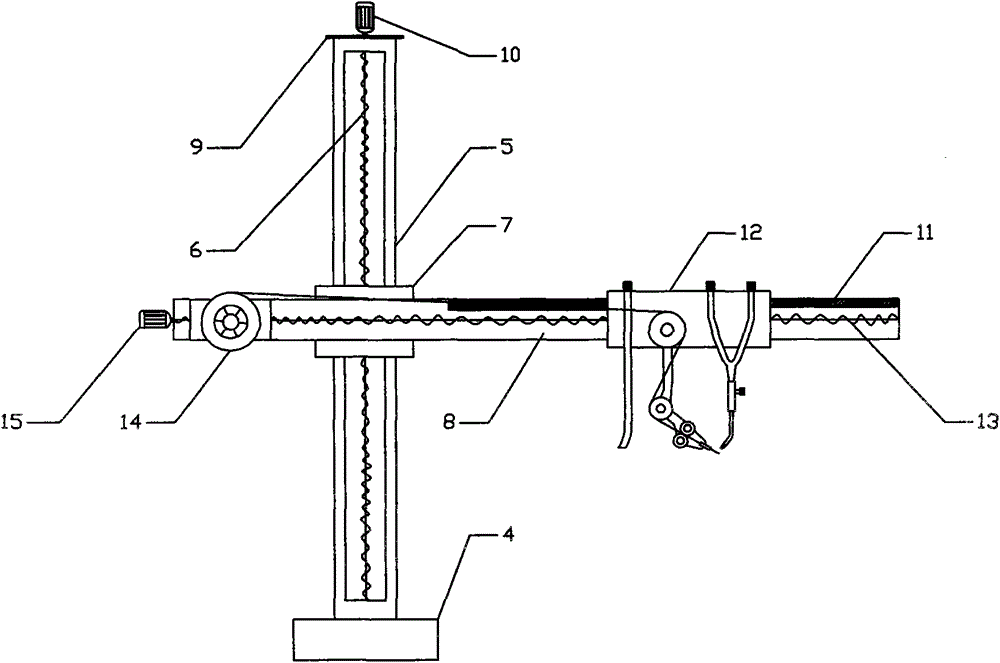

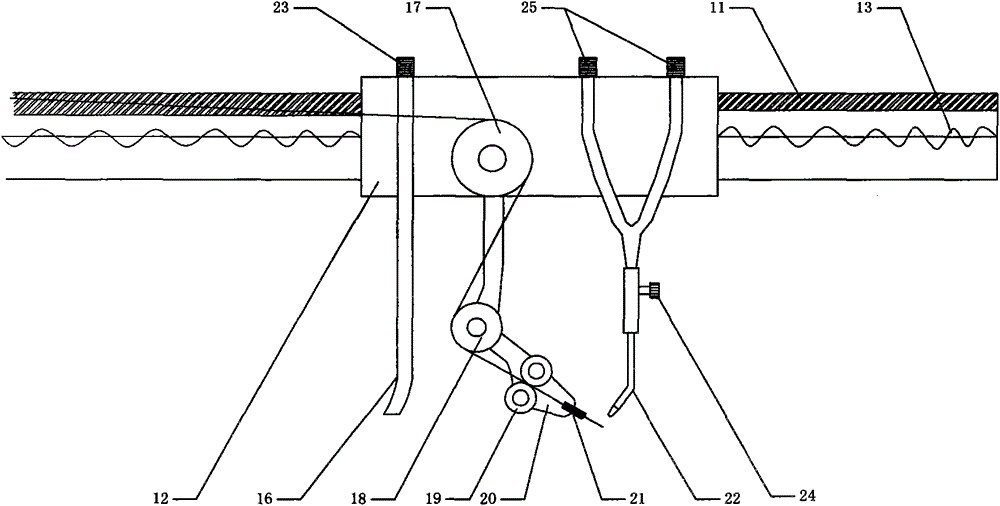

[0030] like figure 1 , 2 , 3, 4 A fully automatic lead filling machine, including lead filling host 2 and auxiliary mechanism 3. A column 5 is installed on the base 4 of the lead-lined host machine 2, and there is a screw rod 6 inside the column 5; the bracket 7 relies on the nut and the screw rod 6 to form a screw nut drive; The top plate 9 and the stepper motor 10 are fixedly placed on the top plate 9. The stepper motor 10 is connected to the screw rod 6 inside the column 5 through a coupling, and the rise and fall of the cross arm 8 is completed by controlling the bracket 7 to adapt to different diameters. The lead-filling requirements of the cylindrical container 1. The stepper motor 15 installed at one end of the cross arm 8 accurately controls the ball screw 13, so that the slide plate 12 can move back and forth accurately on the first guide rail 11 at the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com