Masonry structure of hot blast pipe compensator for hot blast stove

A technology of hot blast pipes and masonry structures, which is applied in the field of hot blast stoves and hot blast stoves in the metallurgical industry. It can solve the problems of increasing enterprise costs, affecting the normal production of blast furnaces, and troublesome production designers with hot blast pipe compensators, so as to avoid overheating, redness, The effect of improving the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

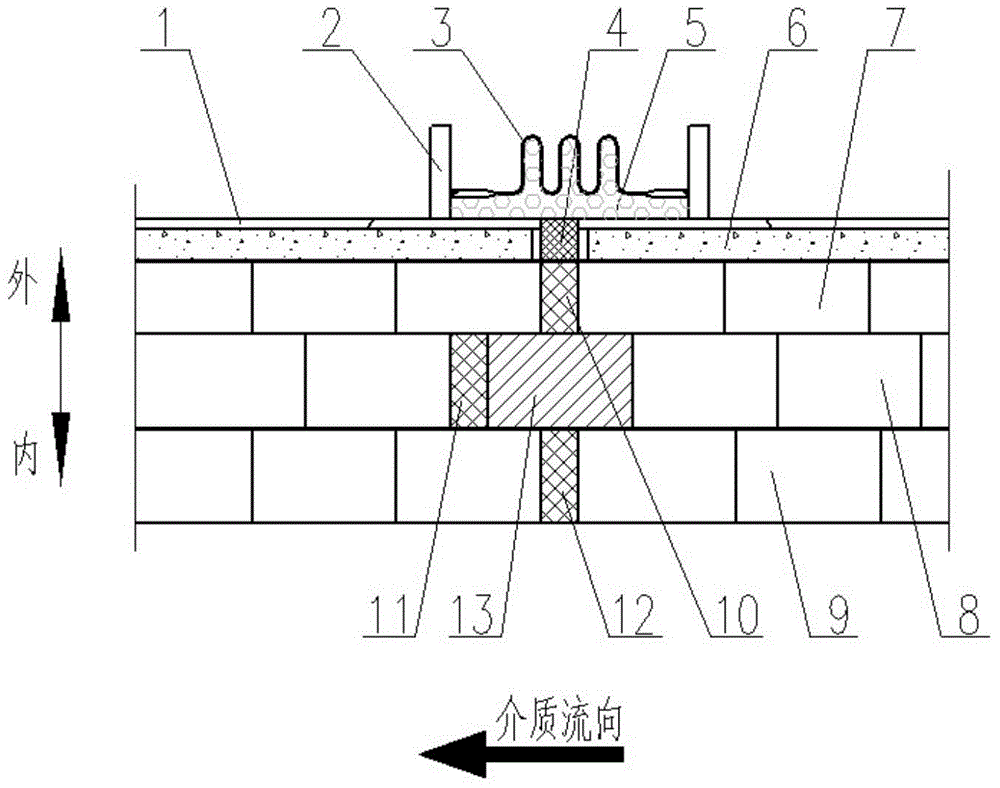

[0025] Figure 2 ~ Figure 4 It is a specific implementation of the present invention.

[0026] Depend on figure 2 It can be seen that the masonry structure of the new hot air pipeline compensator area of the present invention includes: pipeline steel shell 1, ring plate 2, bellows 3, expansion joint 4, heat insulation layer 5, refractory spray paint 6, first layer of heat insulation brick 7 , the second layer of insulating bricks 8, firebricks 9, the expansion joints 10 of the first layer of insulating bricks, the expansion joints 11 of the second layer of insulating bricks, the expansion joints 12 of refractory bricks, and the special-shaped refractory bricks 14.

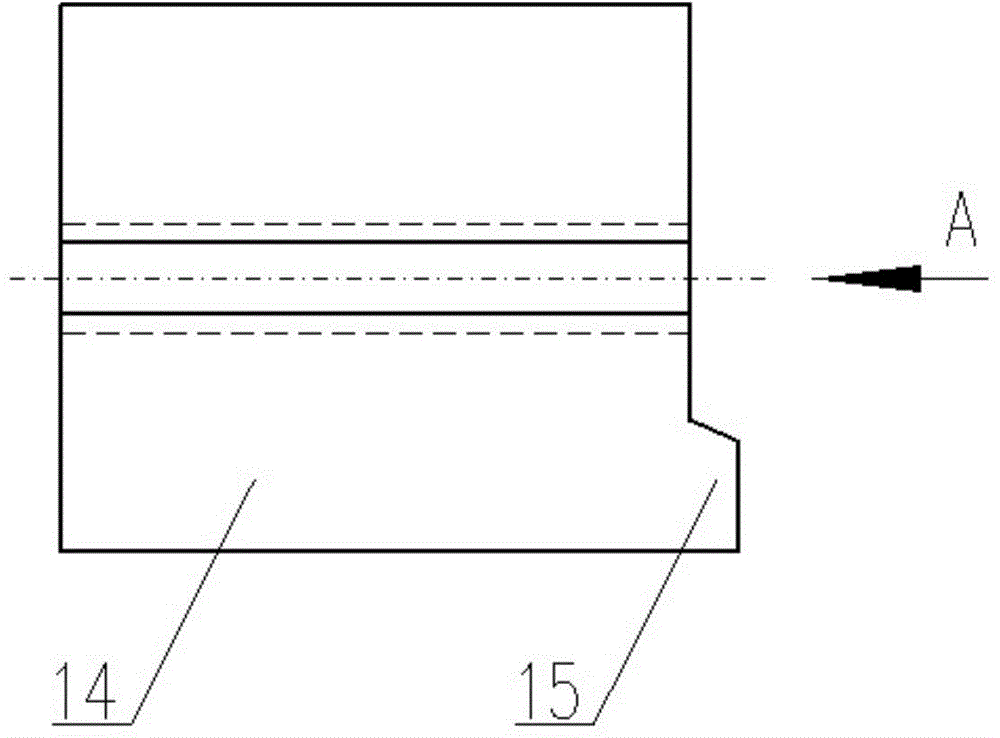

[0027] Depend on image 3 , Figure 4 It can be seen that the special-shaped refractory brick 14 has a first boss 15, the boss form is semicircular or square or trapezoidal, the second boss 16, the boss form is semicircular or square or trapezoidal, groove 17, groove The form is semicircular or square or tra...

Embodiment 2

[0033] In this implementation, the masonry structure in the hot air duct compensator area is figure 2 similar. This embodiment can be adopted when the temperature of the gas medium in the hot air duct is relatively low and only one layer of heat insulating bricks can be built.

[0034] At this time, the masonry structure of the new hot air pipeline compensator area of the present invention includes: pipeline steel shell 1, ring plate 2, bellows 3, expansion joint 4, heat insulation layer 5, refractory spray paint 6, first layer of heat insulation brick 7 , Refractory bricks 9, expansion joints 10 of the first layer of insulating bricks, expansion joints 12 of refractory bricks, and special-shaped refractory bricks 14.

[0035] The special-shaped refractory brick 14 has a first boss 15, the boss form is semicircular or square or trapezoidal, the second boss 16, the boss form is semicircular or square or trapezoidal, groove 17, the groove form is Semicircular or square or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com