Special mix-fruit essence for composite chewing gum

A chewing gum and composite technology, applied in the field of essence, can solve the problems of single flavor type and insufficient natural feeling, and achieve the effect of low production cost, increasing natural feeling and increasing naturalness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The present invention is a kind of conventional mixing process of taking by weighing, taking the present invention of preparing 100KG weight as example, respectively by the weight percentage of each raw material, taking by weighing raw material weight is as follows:

[0019] Ethyl butyrate 12kg, ethyl acetate 4kg, isoamyl acetate 11kg, allyl caproate 5kg, natural menthol 5kg, vanillin 7kg, cold pressed sweet orange oil 10kg, triacetin 22.4kg, isopentyl Ethyl acetate 3kg, methyl salicylate 1.5kg, methyl ionone 4kg, gamma undecalactone 1kg, butyl acetate 0.3kg, butyl butyrate 0.5kg, linalool 1.3kg, citral 3kg, Carvone 1.5kg, isopentyl isovalerate 3kg, ethyl nonanoate 3kg, propyl butyrate 1.5kg.

Embodiment 2

[0021] Take the present invention of preparing 100KG weight as example, respectively by the weight percentage of each raw material, take by weighing raw material weight as follows:

[0022] Ethyl butyrate 11kg, ethyl acetate 3kg, isoamyl acetate 10kg, allyl caproate 4.5kg, natural menthol 4.5kg, vanillin 6kg, cold-pressed sweet orange oil 9kg, glyceryl triacetate 32.1kg, Ethyl isovalerate 2.5kg, methyl salicylate 1.2kg, methyl ionone 3.5kg, gamma undecalactone 0.8kg, butyl acetate 0.4kg, butyl butyrate 0.4kg, linalool 1.1kg , citral 2.8kg, carvone 1.2kg, isopentyl isovalerate 2.5kg, ethyl nonanoate 2.5kg, propyl butyrate 1.0kg.

Embodiment 3

[0024] Take the present invention of preparing 100KG weight as example, respectively by the weight percentage of each raw material, take by weighing raw material weight as follows:

[0025] Ethyl butyrate 11.5kg, ethyl acetate 3.5kg, isoamyl acetate 10.5kg, allyl caproate 4kg, natural menthol 5kg, vanillin 6.5kg, cold pressed sweet orange oil 9.5kg, glyceryl triacetate 29.4kg, ethyl isovalerate 2.0kg, methyl salicylate 1kg, methyl ionone 3kg, gamma undecalactone 0.9kg, butyl acetate 0.3kg, butyl butyrate 0.5kg, linalool 1.2 kg, citral 2.9kg, carvone 1.3kg, isopentyl isovalerate 2.8kg, ethyl nonanoate 2.8kg, propyl butyrate 1.4kg.

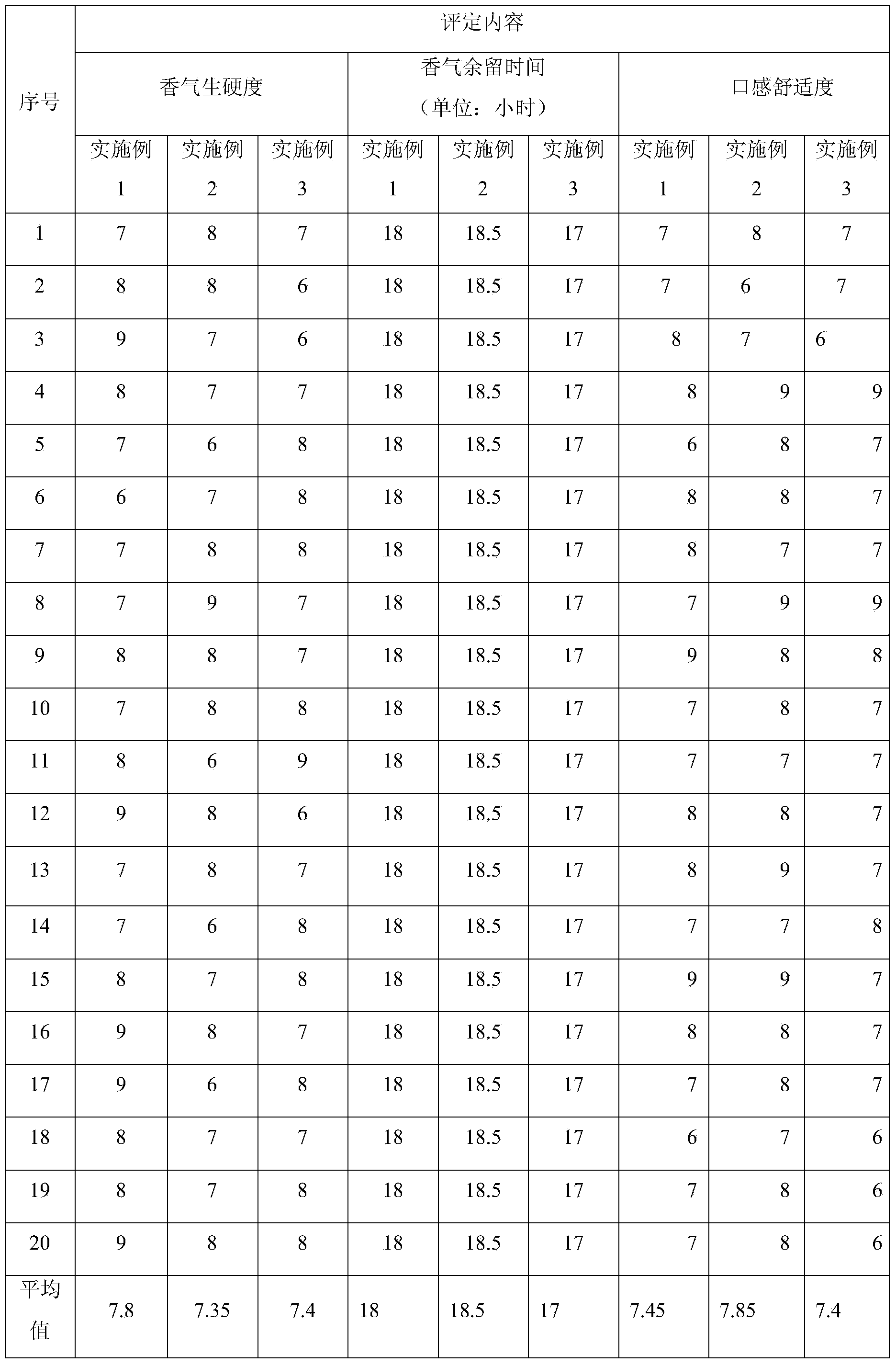

[0026] Regarding the component ratios of the raw materials in the above examples, the present invention invites 20 judges (10 men and 10 women, respectively numbered 1 to 20) with normal sense of smell to evaluate the hardness of the aroma produced by the above three examples. , fragrance remaining time and taste comfort were evaluated, and the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com