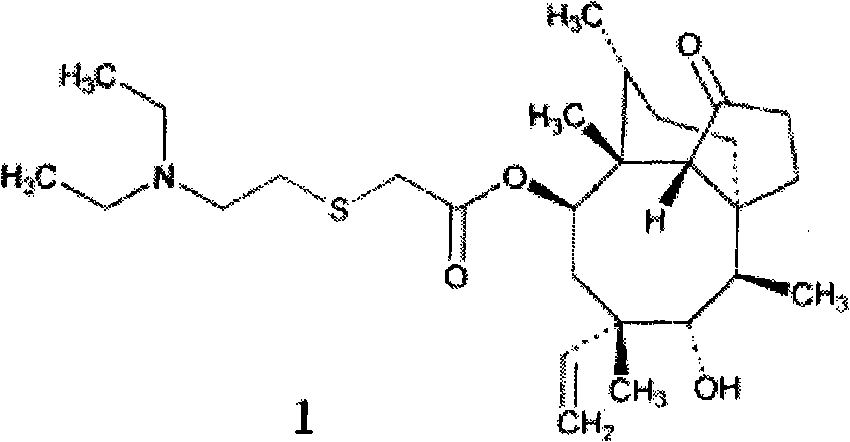

A kind of purification method of tiamulin reaction liquid in industrial production

A tiamulin and purification method technology, applied in chemical instruments and methods, organic chemistry, preparation of organic compounds, etc., can solve the problems of complexity, high cost, complex tiamulin production process, etc., and achieve simplified purification method , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

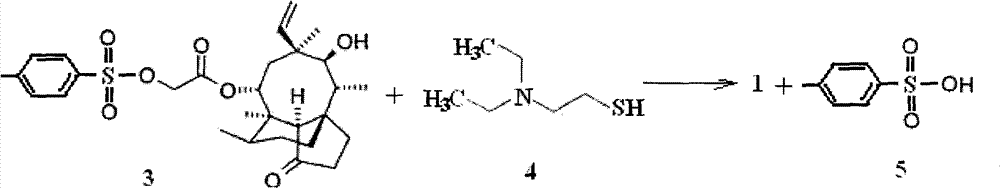

Method used

Image

Examples

Embodiment 1

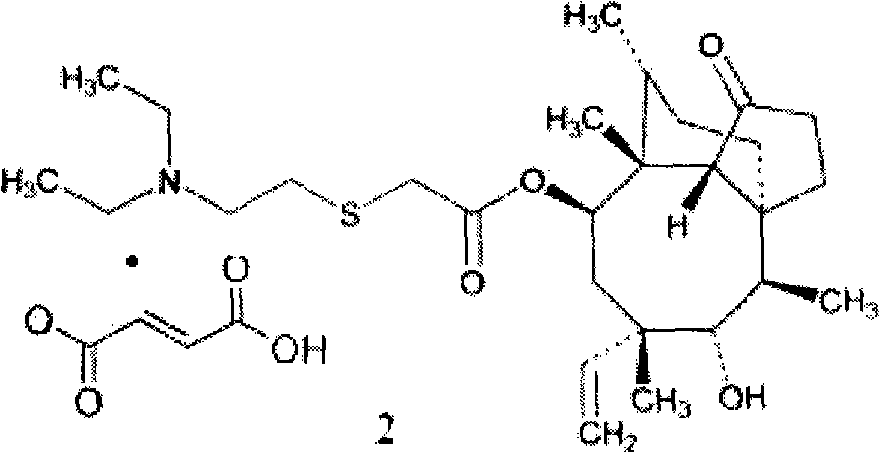

[0018] According to the method for synthesizing tiamulin in U.S. Patent US4278674 and British Patent GB1410505, and the corresponding raw materials, catalyst and solvent proportioning, pleuromutilin p-toluenesulfonate ester of 106 grams (1.0 moles) and equimolar 2- Diethylaminoethanethiol hydrochloride was reacted, and the solid obtained by concentrating was dissolved in 850 ml of ethyl acetate, washed with water (500 ml × 2), and the reaction solution was neutralized to pH6.7 with 10% phosphoric acid. Then it was washed with water (300 ml×2) to obtain a tiamulin-ethyl acetate solution with a chromatographic purity of 98.5%. The solution can be directly used to react with fumaric acid to synthesize tiamulin fumarate.

Embodiment 2

[0020] According to the method for synthesizing tiamulin in U.S. Patent US4278674 and British Patent GB1410505, and the corresponding raw materials, catalyst and solvent proportioning, pleuromutilin p-toluenesulfonate ester of 106 grams (1.0 moles) and equimolar 2- Diethylaminoethanethiol hydrochloride was reacted, and the concentrated obtained solid was dissolved in 800 ml of ethyl acetate, then after washing with water (500 ml × 2), the reaction solution was neutralized to pH7.0 with 10% phosphoric acid , and then washed with water (300 ml×2), to obtain a tiamulin-ethyl acetate solution with a chromatographic purity of 98.0%. The solution can be directly used to react with fumaric acid to synthesize tiamulin fumarate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chromatographic purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com