A fully automatic raw material tape splitting machine

A technology of raw material tape and coiler, which is applied in the direction of coiling strips, thin material processing, transportation and packaging, etc. It can solve problems such as irregularities, low production efficiency, and uneven coiling of raw material tapes, and achieve a wide range of applications. Market promotion prospects, high degree of full automation, novel and unique design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

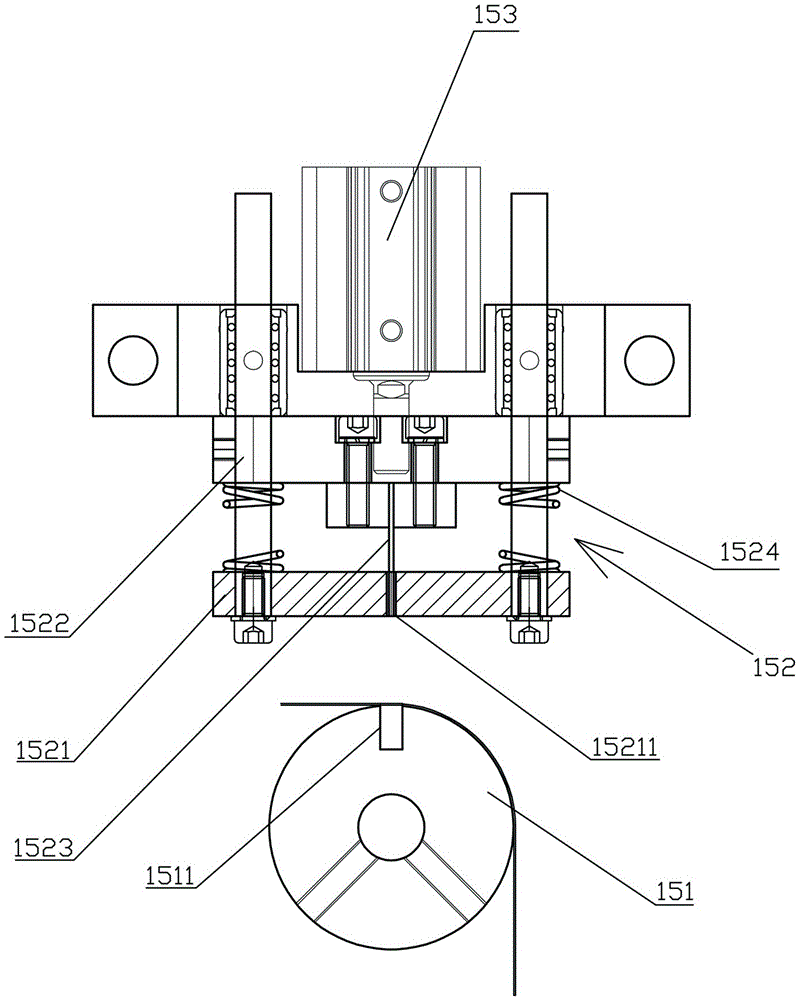

[0030] like figure 1 , figure 2 and image 3 As shown, a fully automatic raw material tape rewinding machine includes a frame body 1, a power drive mechanism and a control system 3; the frame body 1 is provided with a rotatable indexing turntable 11, the indexing turntable 11 There is a central rotating shaft 111 that drives the indexing turntable 11 to rotate and three rotating shafts 112 that are evenly distributed around the circumference and can rotate independently; : The winding core device 12 for automatically winding the core on the rotating shaft 112 of the indexing turntable 11, the feeding device 13 for transferring the raw material tape to the winding core on the indexing turntable 11 and winding, The bonding device 14 for bonding the tape to the core, the cutting device 15 for cutting the raw tape, the tail press 16 for flatte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com