Quantitative liquid injection device for dosing of chemical engineering liquid raw materials

A technology for chemical liquids and injectors, which is applied in the directions of distribution devices, packaging, transportation and packaging to achieve the effect of easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

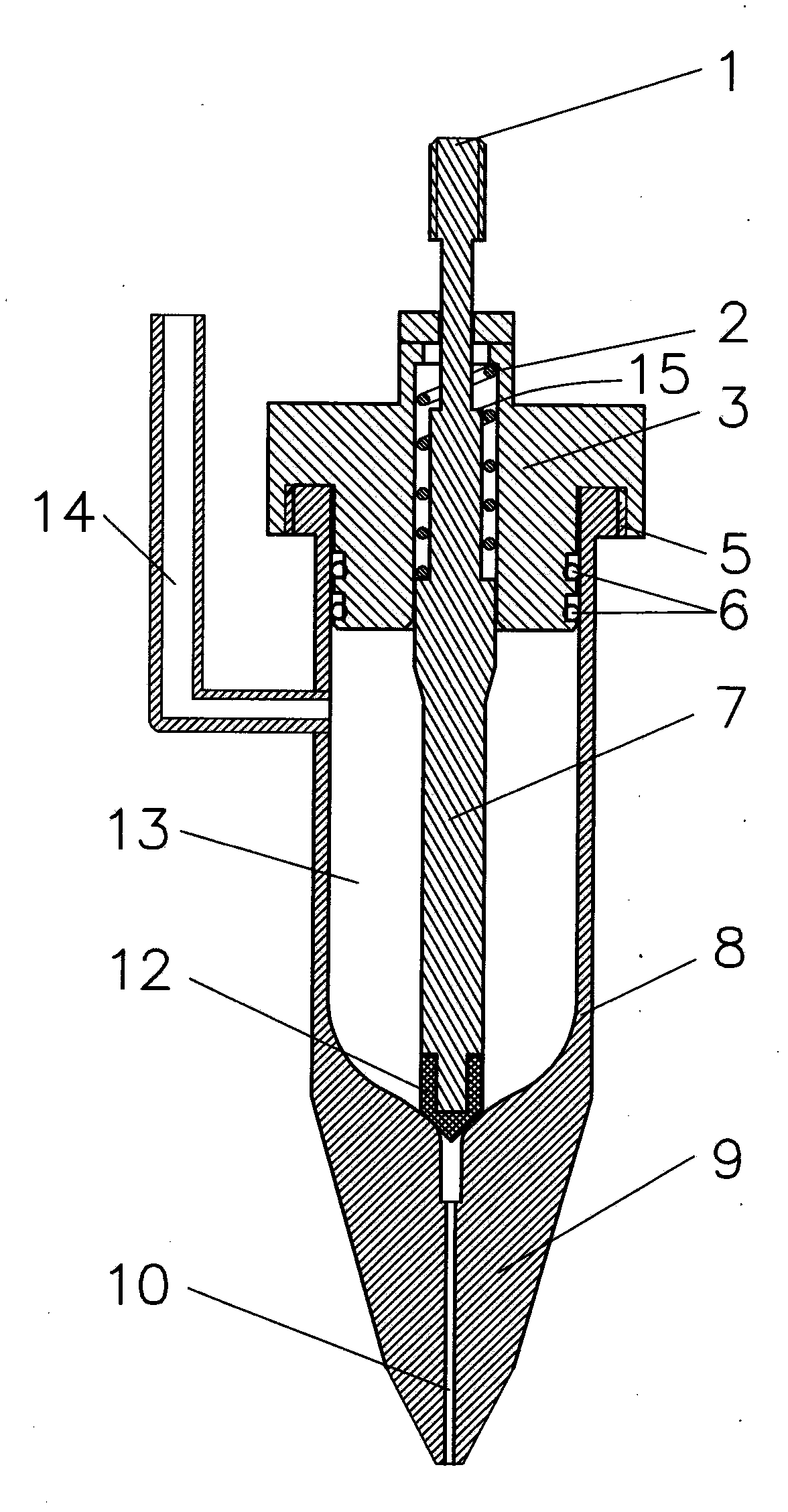

[0009] refer to figure 1 It can be seen that the present invention is composed of a liquid injection cylinder 8, a connecting block 3, a liquid injection head 9, and a piston rod 7. The lower end of the liquid injection cylinder is provided with a liquid injection head 9, and the inside of the liquid injection cylinder is provided with an inner cavity 13, and the injection The liquid head is integrated with the liquid injection cylinder, the inner side of the lower end of the liquid injection cylinder is provided with a liquid injection hole 10, the lower end of the piston rod is provided with a rubber plug 12, and the rubber plug is connected with the upper end of the liquid injection hole, and the up and down movements of the piston rod can be linked The rubber plug is tightly connected or separated from the upper end of the injection hole 10, the upper end of the piston rod is provided with a connecting handle 1, and the connecting block 3 is provided with a connecting block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com