High-speed full-automatic capsule vision detector

A fully automatic, detection machine technology, applied in sorting and other directions, can solve the problems of missed detection, wrong detection, low work efficiency, complex structure, etc., to prevent central position retention, solve low detection efficiency, and simplify arrangement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

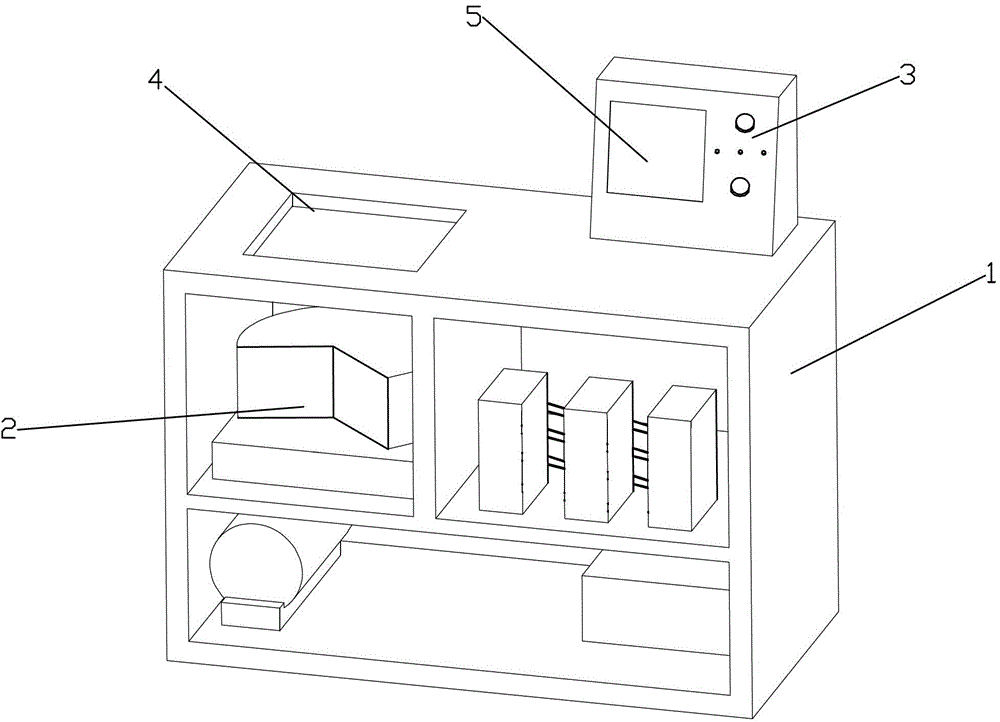

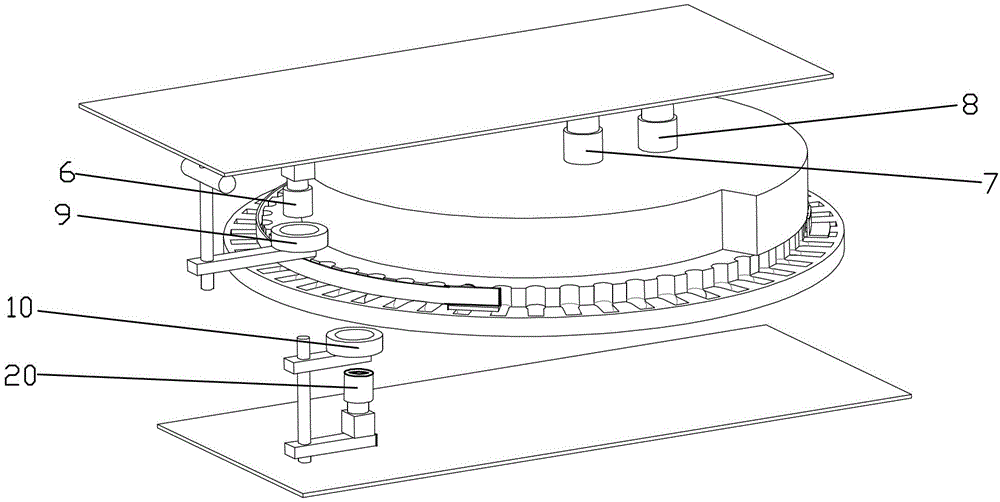

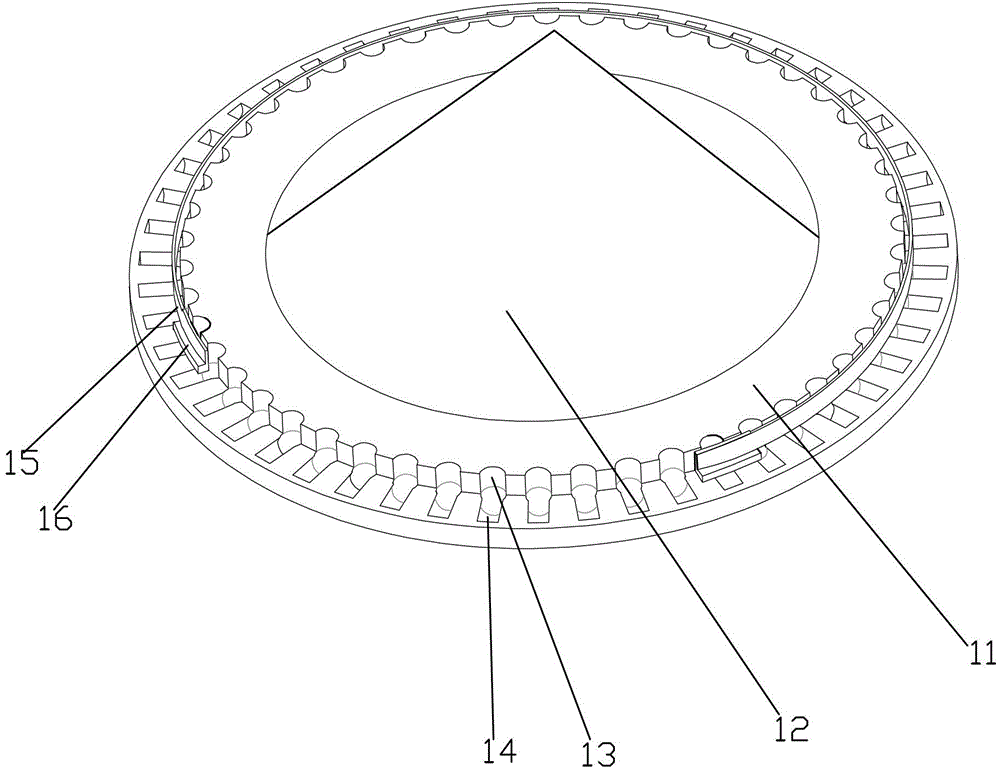

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the high-speed automatic capsule visual inspection machine of the present invention includes a frame 1, an arrangement device 2, a detection device, a control system 3, a rejecting device and a feed bin 4, and the arrangement device 2 is installed on the left side of the frame 1, and the arrangement The device 2 includes an arrangement turntable 11 and a cone 12, the cone 12 is installed at the center of the arrangement turntable 11, the feed bin 4 is located above the cone 12, and the detection device includes a capsule shell body detection device and a capsule end detection device, the capsule shell body The detection device is installed above the arrangement turntable 11, and the capsule end detection device is located below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com