Full-automatic rubber injection gun

A glue injection gun, fully automatic technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve problems such as affecting work efficiency, affecting the service life of the automatic glue gun, pushing the rod upturning and even causing deformation, etc. , to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

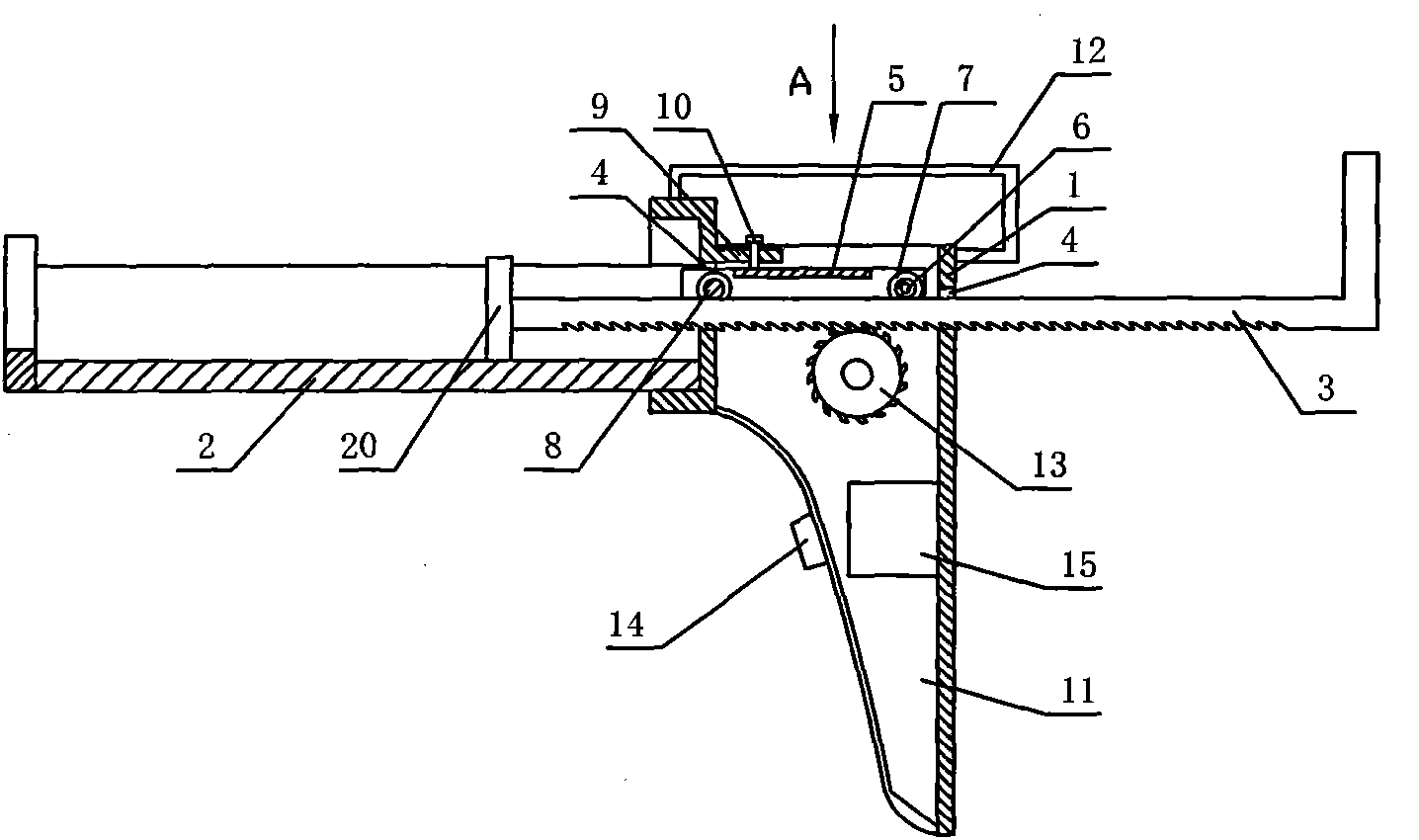

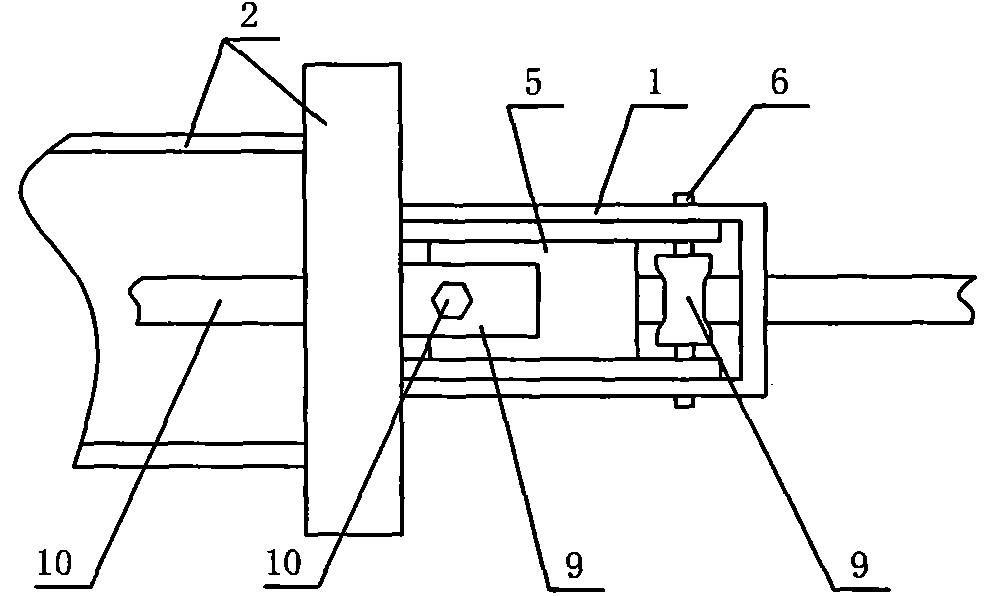

[0013] Such as figure 1 The fully automatic glue injection gun shown includes a support frame 1 and a hose bracket 2 connected to the front end of the support frame 1. The rear part of the hose bracket 2 and the support frame 1 is correspondingly provided with a through hole 4, and the through hole 4 is worn There is a cylindrical push rod 3, the front part of the push rod 3 is fixed with a push plate 20 sliding along the hose bracket 2, the fixed handle 11 at the lower part of the rear end of the support frame 1, and the surface of the push rod 3 is provided with a front facing A row of planar tooth lines arranged in the rear, the fixed handle 11 is rotatably connected with a driving gear 13 driven by the forward and reverse motor 15 and meshed with the planar tooth lines on the push rod, and the fixed handle 11 is equipped with a device to control the rotation of the forward and reverse motor. The electric button 14. After the glue injection is completed, the push rod 3 nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com