heating circulation pump

A heating cycle, pump housing technology, applied in the direction of pumps, pump devices, non-variable-capacity pumps, etc., to achieve the effect of beautiful design, conducive to packaging and storage, and reducing the diversity of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

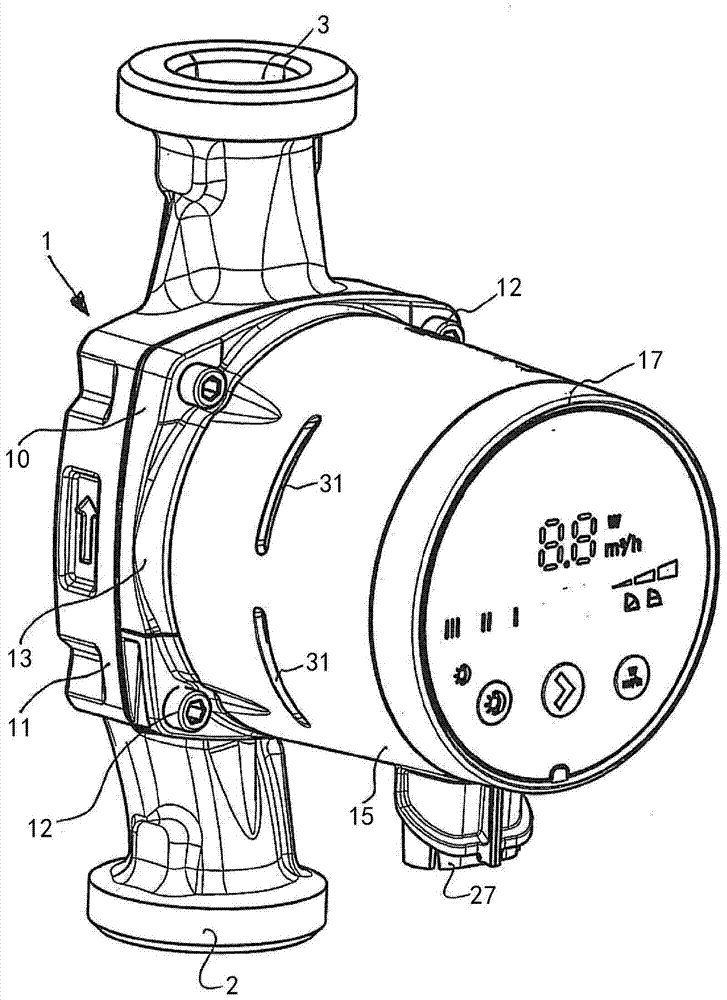

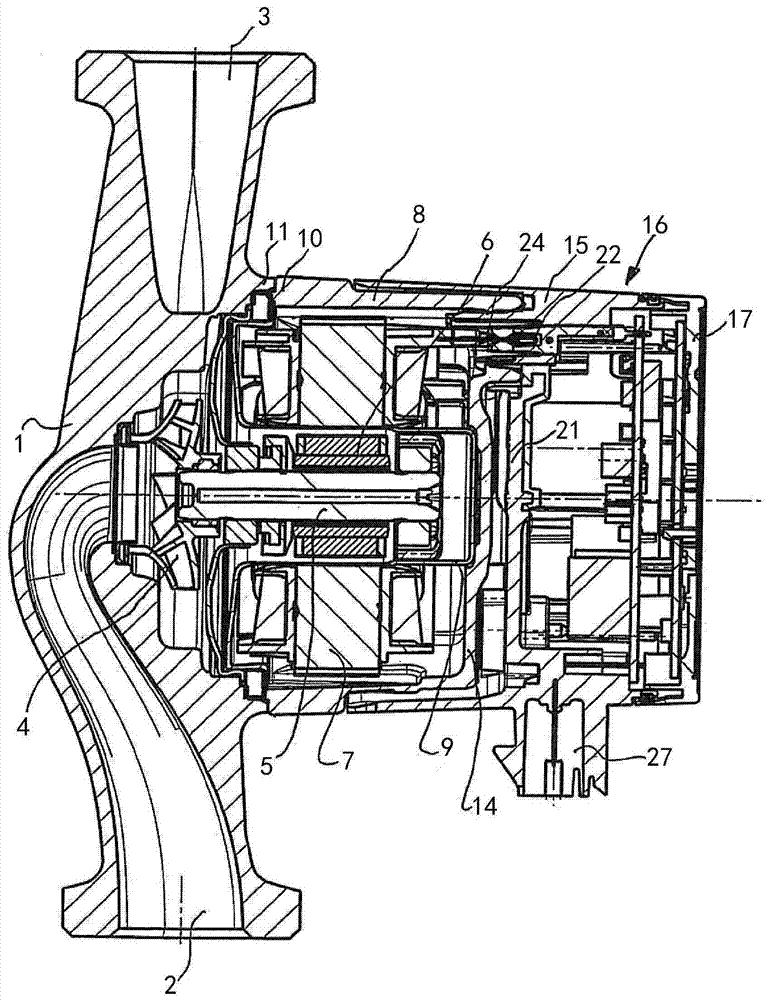

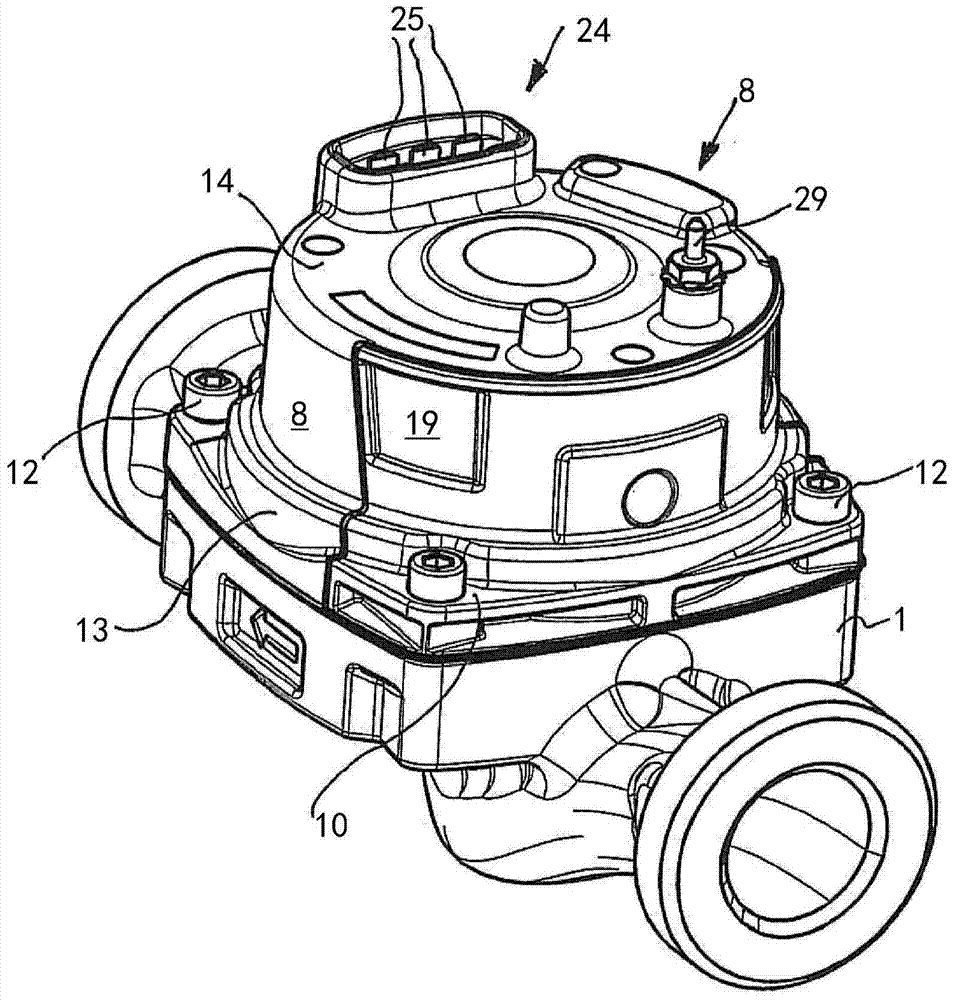

[0027]The heating circulation pump shown in the figure has a pump housing 1 comprising a suction sleeve 2 and a pressure sleeve 3 . A pump impeller 4 is rotatably arranged in the pump housing 1 in order to convey the conveying liquid at high pressure from the suction sleeve 2 into the pressure sleeve 3 in a known manner by rotating the pump impeller 4 . The pump impeller 4 is arranged on the shaft 5 , which simultaneously carries the rotor 6 of the electric motor, and the stator 7 of the electric motor is arranged in the stator housing 8 . The motor is a wet-running motor and has a liquid-filled slot 9 between the rotor 6 and the stator 7 .

[0028] The pump housing 1 is designed to be open relative to the stator housing 8 . At its pump-side end, the stator housing 8 has a flange 10 which is connected to a flange 11 of the pump housing 1 and has a rounded square contour. Due to the circular design of the other part of the stator housing 8 , there will be a part in which the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com