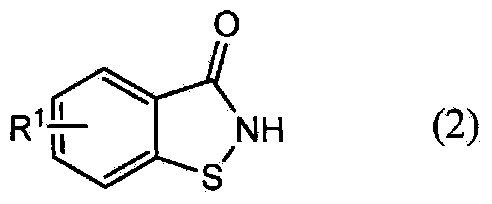

Method for producing 1,2-enzisothiazol-3-one compound

A technology of benzisothiazole and ketone compounds, applied in the direction of organic chemical methods, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of increasing waste water and undesired needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] (i) Synthesis of methyl mercaptan

[0135] A 20% aqueous solution (280 g) of sodium hydrosulfide (1.00 mol), chlorobenzene (200 g), and a 50% by weight aqueous solution (3.2 g) of tetra-n-butylammonium bromide were placed under a nitrogen atmosphere equipped with a stirrer, In a 500mL four-necked flask with a thermometer, a condenser and a gas blow tube. The mixture was stirred at 30°C.

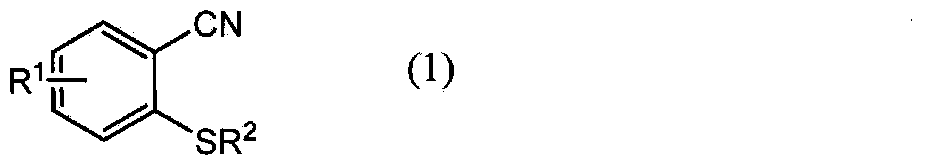

[0136] 2-(Methylthio)benzonitrile (298.0 g, 2.0 moles), monochlorobenzene (460.0 g) and 35% by weight hydrochloric acid (67.0 g, hydrochloric acid: 0.6 moles, water: 2.4 moles) were placed in a stirrer equipped with , a thermometer and a condenser in a 3L four-necked flask. Sulfonyl chloride (270.0 g, 2.0 mol) was added thereto while stirring at 5°C to 15°C. The mixture was further heated to 65-70°C and allowed to react for 1 hour. Gas generated during the reaction was passed through 15% aqueous sodium hydroxide to remove hydrogen chloride. The obtained methyl chloride gas (50.5...

Embodiment 2

[0145] (i) Synthesis of ethanethiol

[0146] Under a nitrogen atmosphere, a 20% aqueous solution (280 g) of sodium hydrosulfide (1.00 mol), chlorobenzene (100 g) and a 50% by weight aqueous solution (3.2 g) of tetra-n-butylammonium bromide were placed in a device equipped with a stirrer, a thermometer, , condenser and blow tube in a 500mL four-necked flask. The mixture was stirred at 30°C.

[0147] 2-(Ethylthio)benzonitrile (326.0 g, 2.0 moles), monochlorobenzene (460.0 g) and 35% by weight hydrochloric acid (67.0 g, hydrochloric acid: 0.6 moles, water: 2.4 moles) were placed in a stirrer equipped with , a thermometer and a condenser in a 3L four-necked flask. While stirring, chlorine gas (156.0 g, 2.2 mol) was blown thereinto at 45°C˜50°C over 2 hours, and the resulting mixture was further heated to 65°C˜70°C and then allowed to react for 1 hour. Gas generated during the reaction was passed through 15% aqueous sodium hydroxide to remove hydrogen chloride. The resulting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com