Adjustable automatic rotary smoke exhaust valve

A technology of automatic rotation and smoke exhaust valve, applied in the direction of valve details, valve device, functional valve type, etc., can solve the problems of affecting the quality and efficiency of smoke exhaust, difficult reset, no wind speed at the exhaust valve port, etc., to improve quality and efficiency. Efficiency, solving reset difficulties, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

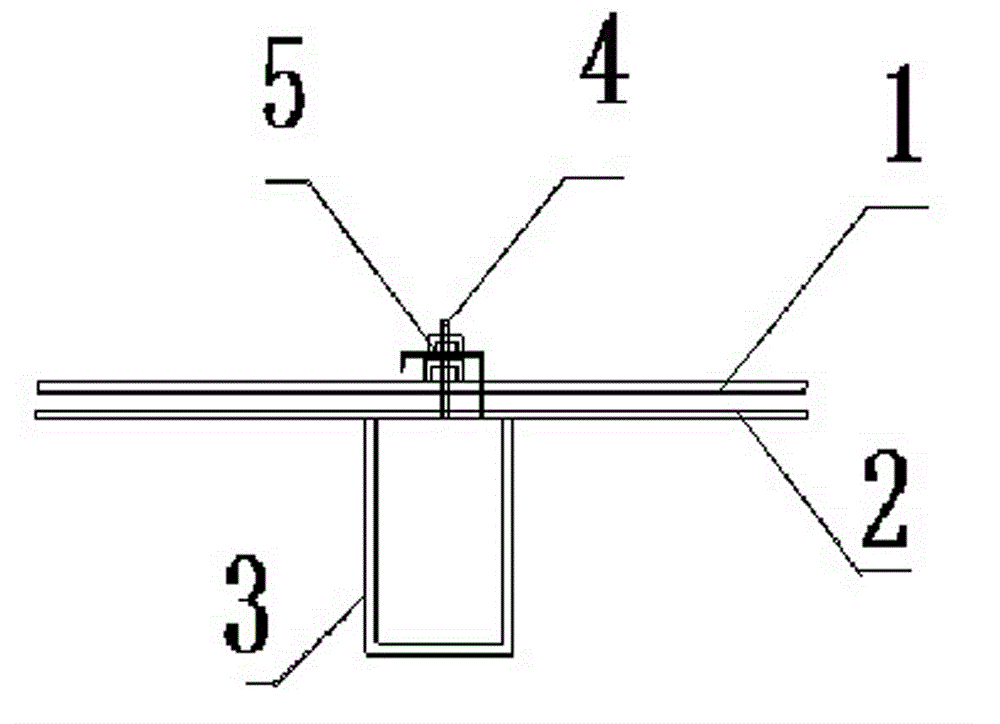

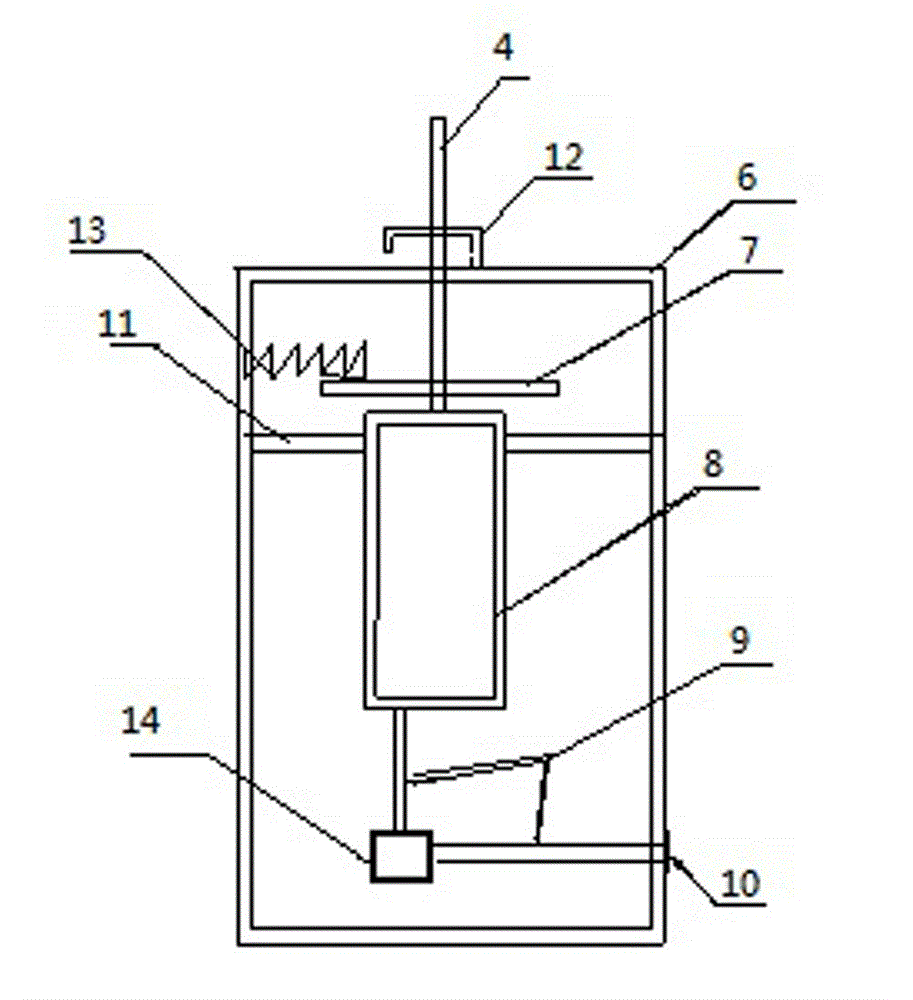

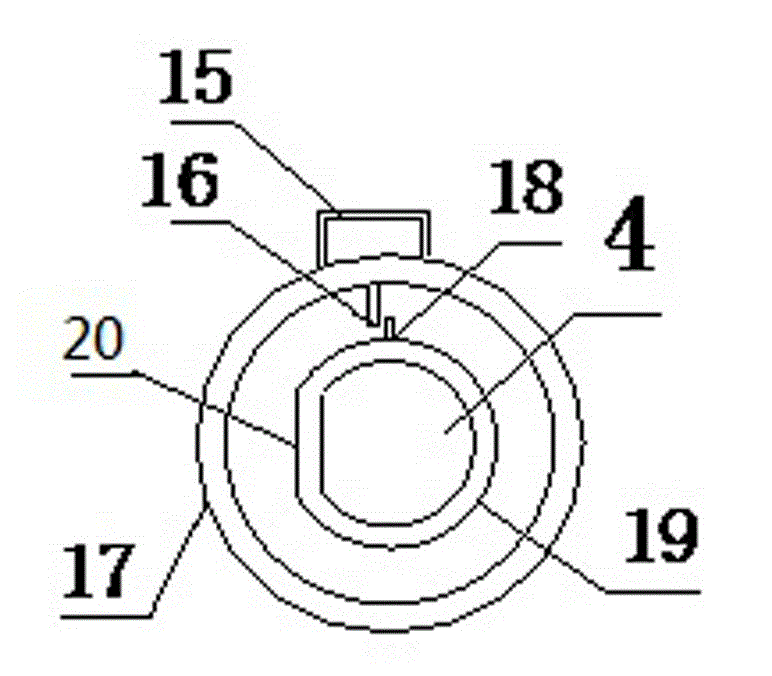

[0012] The opening and closing device 3 includes a rotating shaft 4, a turntable 7, an adjustable limiter 12, a return spring 13, a thermal fuse switch 14, a low-voltage DC motor 8, a fixing frame 11, a junction box 10 and a protective shell 6; the upper end of the protective shell 6 is fixed and fixed The grid 2 is connected, the low-voltage DC motor 8 is installed in the protective shell 6 through the fixing frame 11; the turntable 7 is fixed on the rotating shaft 4, one end of the return spring 13 is fixed on the protective shell 6 and the other end is fixed on the turntable 7. The adjustable stopper 12 includes a fixed piece 17 and a rotating piece 19. The fixed piece 17 is a hollow circular steel plate. The outer and inner sides of the circular steel plate are respectively provided with a locking protrusion 15 and a blocking protrusion 片16. The rotating piece 19 is a hollow ring-shaped steel piece, the size of the steel piece is smaller than the fixed piece 17, the outer si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com