Friction driving device of torsional spring resetting type

A friction-driven, resetting technology, applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve problems such as complex structure, many parts, difficult structure, low cost, etc., to achieve enhanced reliability, structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

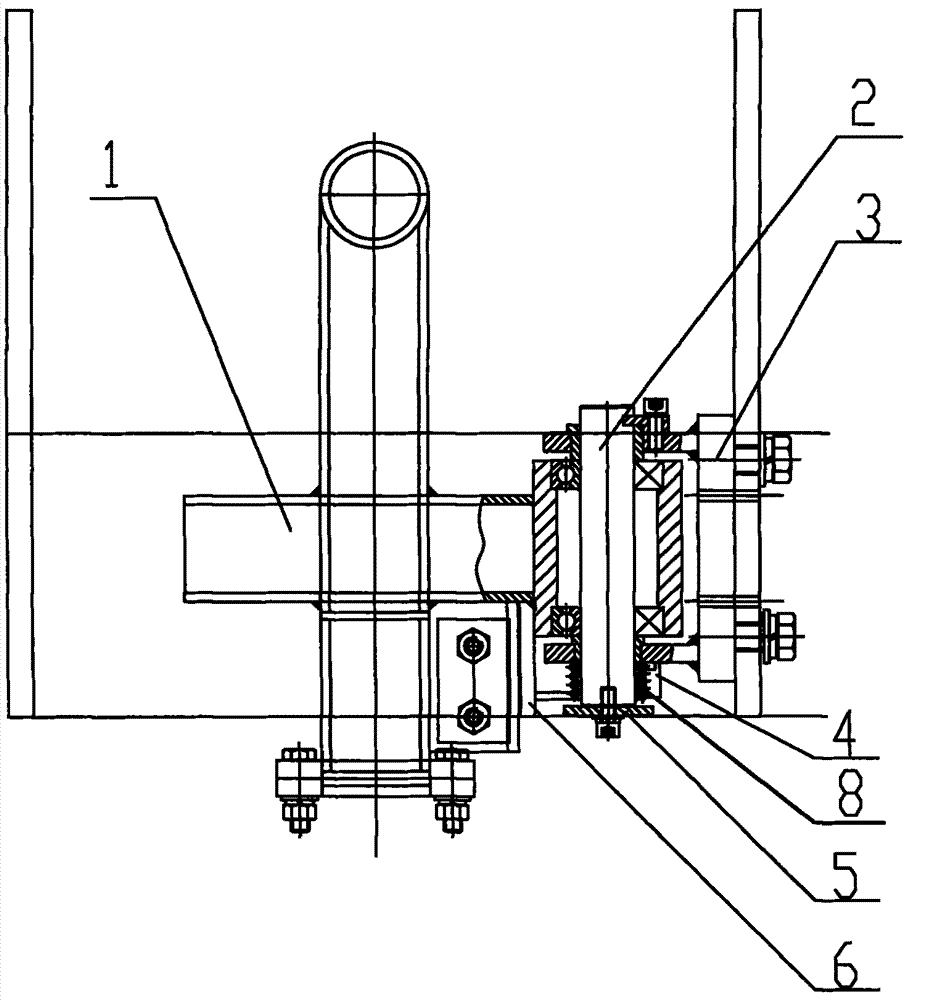

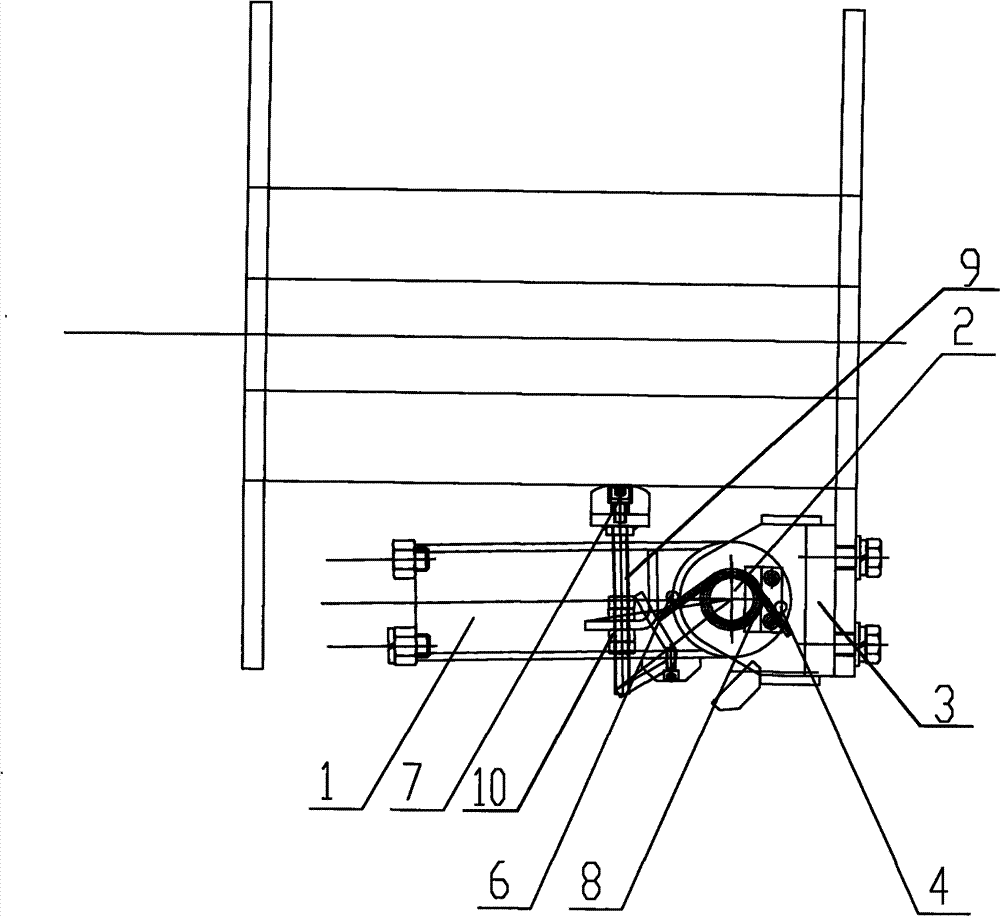

[0010] As shown in the figure, the present invention mainly consists of a movable bracket 1, a connecting mandrel 2, a fixed bracket 3, a first torsion spring limiting plate 4, a torsion spring baffle plate 5, a second torsion spring limiting plate 6, and a limiting block 7, components such as torsion spring 8, adjusting screw rod 9 and adjusting nut 10 are formed.

[0011] The torsion spring reset type friction drive device includes a movable support 1 and a fixed support 3, the movable support 1 is hinged on the fixed support 3 through the connecting mandrel 2, and the second torsion spring limiting plate 6 is fixedly connected to the movable support 1, A first torsion spring limiting plate 4 is fixedly connected to the fixed bracket 3, a torsion spring 8 is sleeved on the connecting mandrel 2, and one end of the torsion spring 8 leans against the first torsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com