Automatic assembly equipment for bottle caps with lifting ropes

A technology for automatic assembly and bottle caps, applied in metal processing equipment, devices for coating liquid on the surface, metal processing, etc., can solve the problems of numerous steps, time-consuming and labor-intensive, inability to effectively improve efficiency, etc., and achieve stable and reliable structure, Improve work efficiency and prevent excessive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

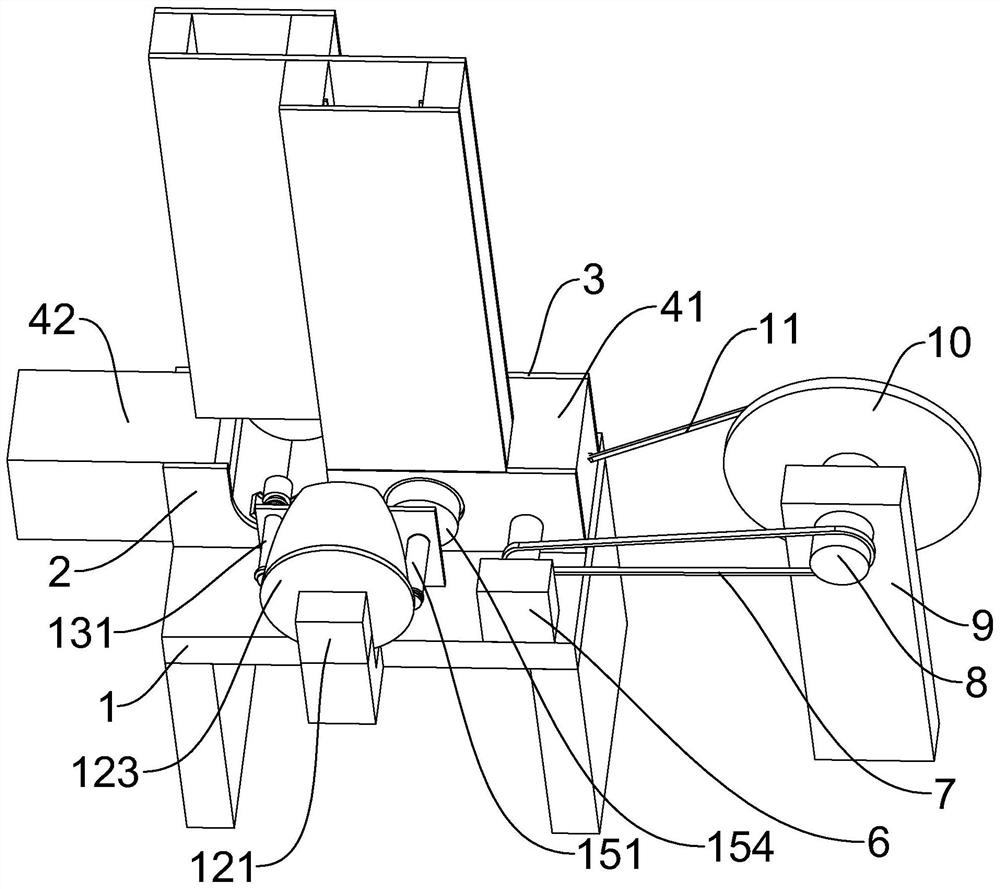

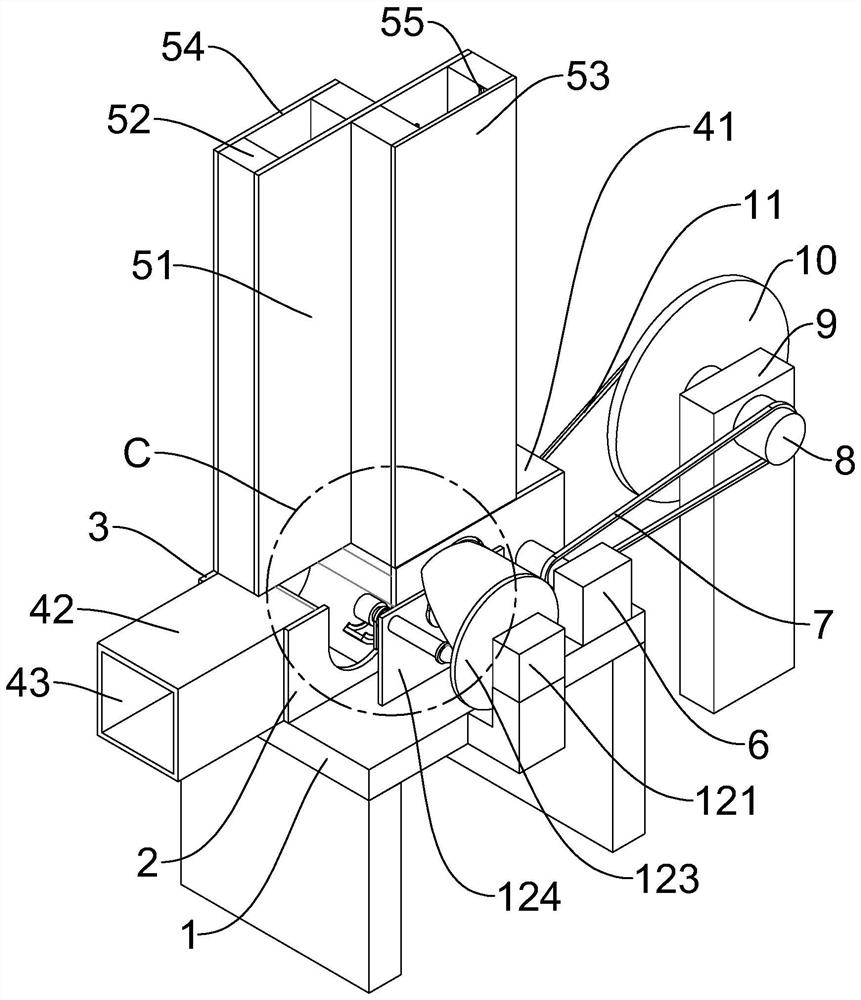

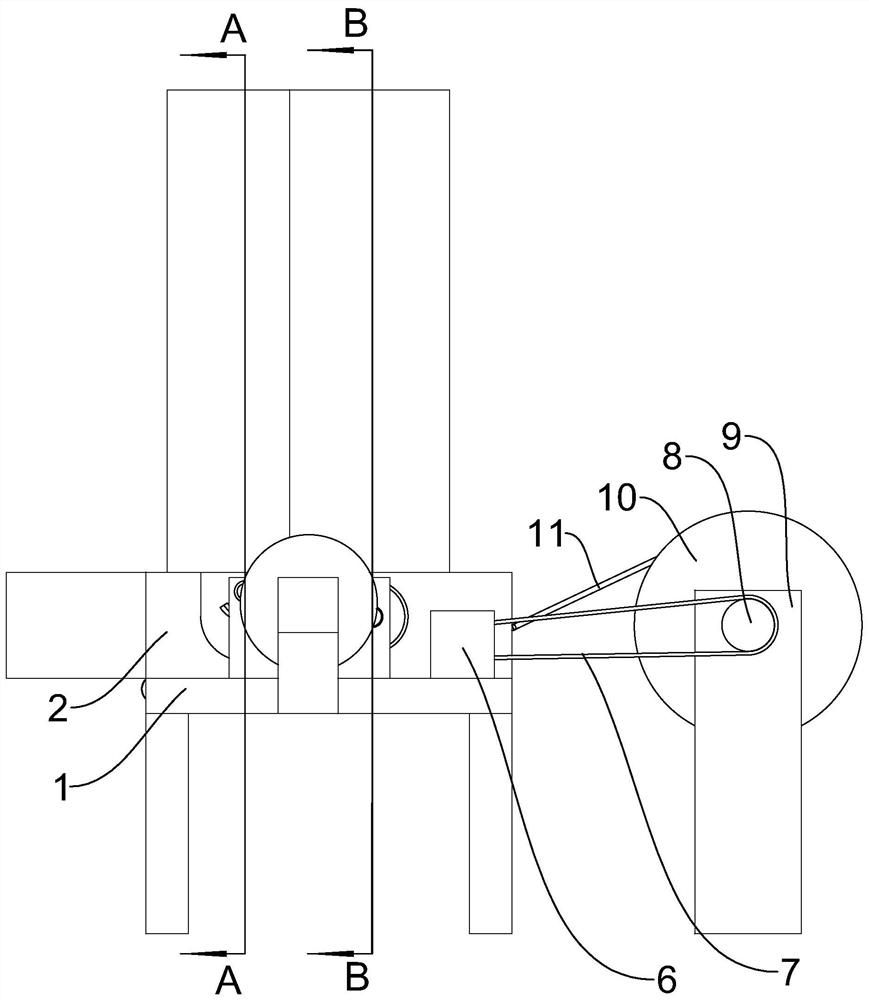

[0038] Such as Figure 1 to Figure 17 As shown, an automatic assembly device for a rope bottle cap includes vertical blocks on the left and right sides, the upper end of the vertical block is provided with a platform 1, and the upper end of the platform 1 is provided with a front baffle 2 and a rear baffle 3 arranged in parallel, The upper end of the front baffle 2 and the rear baffle 3 is provided with a blanking box 5 for blanking the outer cover and the inner cover, and the platform 1, the front baffle 2, the rear baffle 3, and the blanking box 5 are equipped with a conveyor Part 4, the upper end of the conveying part 4 is provided with a U-shaped groove, the upper end of the platform 1 is provided with a first stepping motor 6, the right side of the vertical block on the right is provided with a support block 9, and the upper end of the support block 9 is rotatably provided with The first rotating shaft 8, the first rotating shaft 8, and the output shaft of the first stepp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com