Coal mine rock stratum mobile control mining-filling-preserving coupled coordination mining method

A mining method and coal mine technology, which is applied in ground mining, earth square drilling, underground mining, etc., can solve problems such as easy water accumulation, difficult relocation measures, and large amount of coal pressure, so as to reduce surface movement deformation and improve surrounding rock condition, the effect of improving the stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

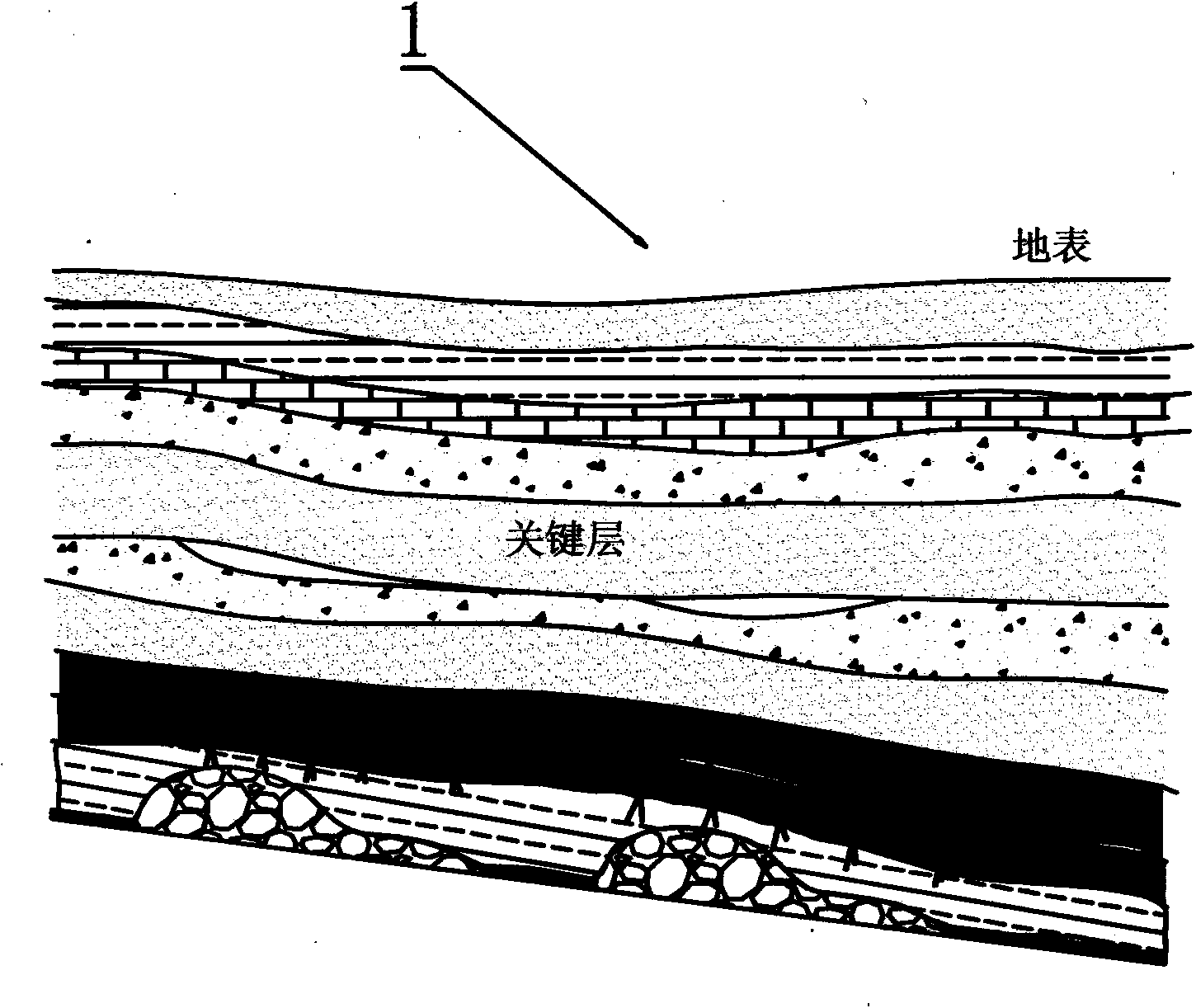

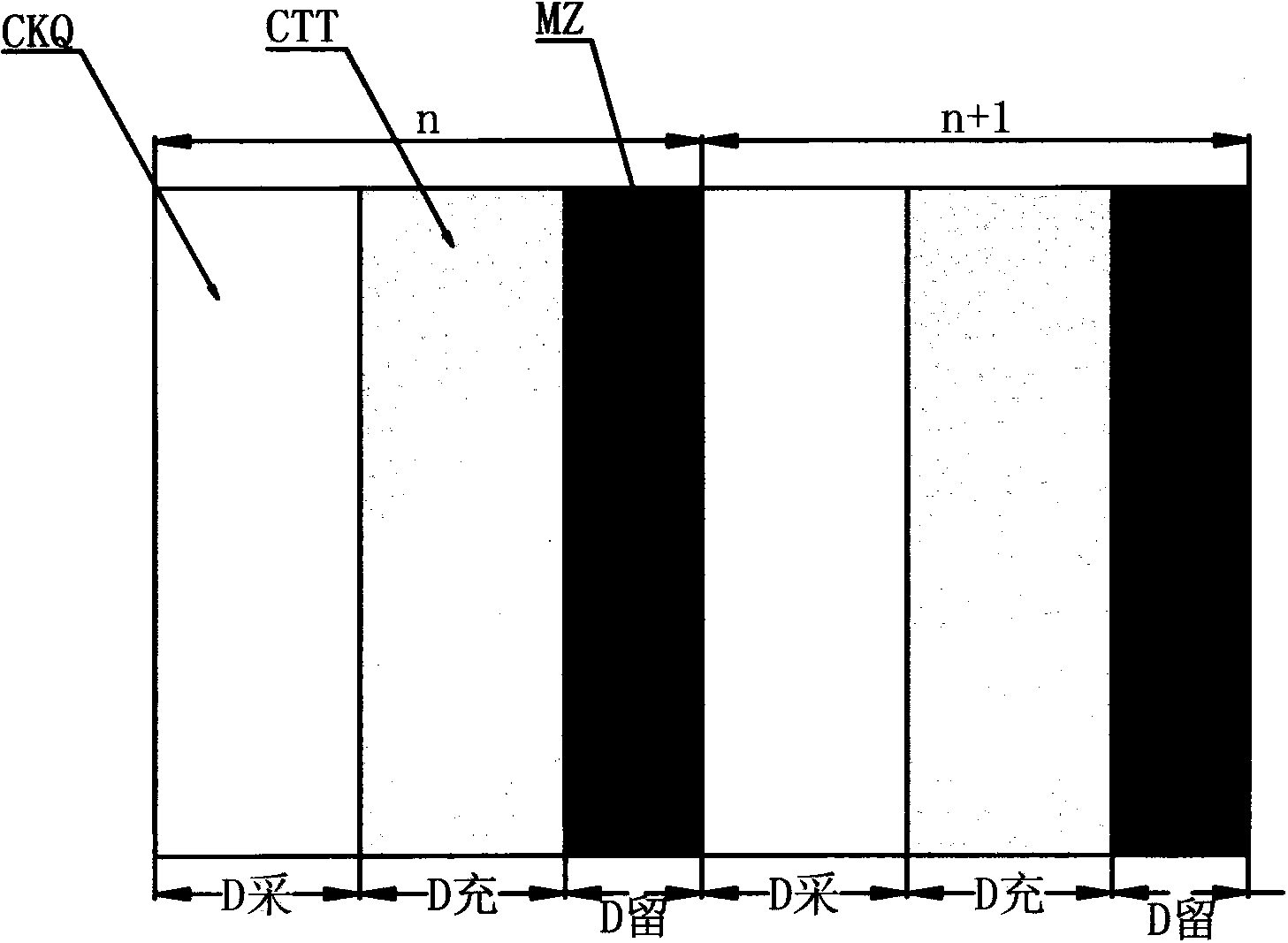

[0038] Such as Figure 1a and Figure 1a ’, the coal mine mining area 1 is divided into m mining units, where m is a positive integer; each mining unit adopts one-sided filling Mining in single-side filling mode is to arrange a filling working face and a non-filling working face in sequence on the side of the reserved coal pillar MZ; firstly, the filling working face mining is carried out in the filling method mining unit area of the N mining unit n and filling to form a filling body CTT; and then carry out non-filling working face mining in all caving mining unit areas of the N mining unit n to form a goaf CKQ, where n is a positive integer and m is less than or equal to n; two adjacent The coal pillar MZ of a mining unit is adjacent to the goaf CKQ. With the reserved coal pillar MZ as the core, the coal pillar MZ, filling body CTT and caving body coordinately support the overlying rock mass, and control the movement and deformation values of the rock formation and the su...

Embodiment 2

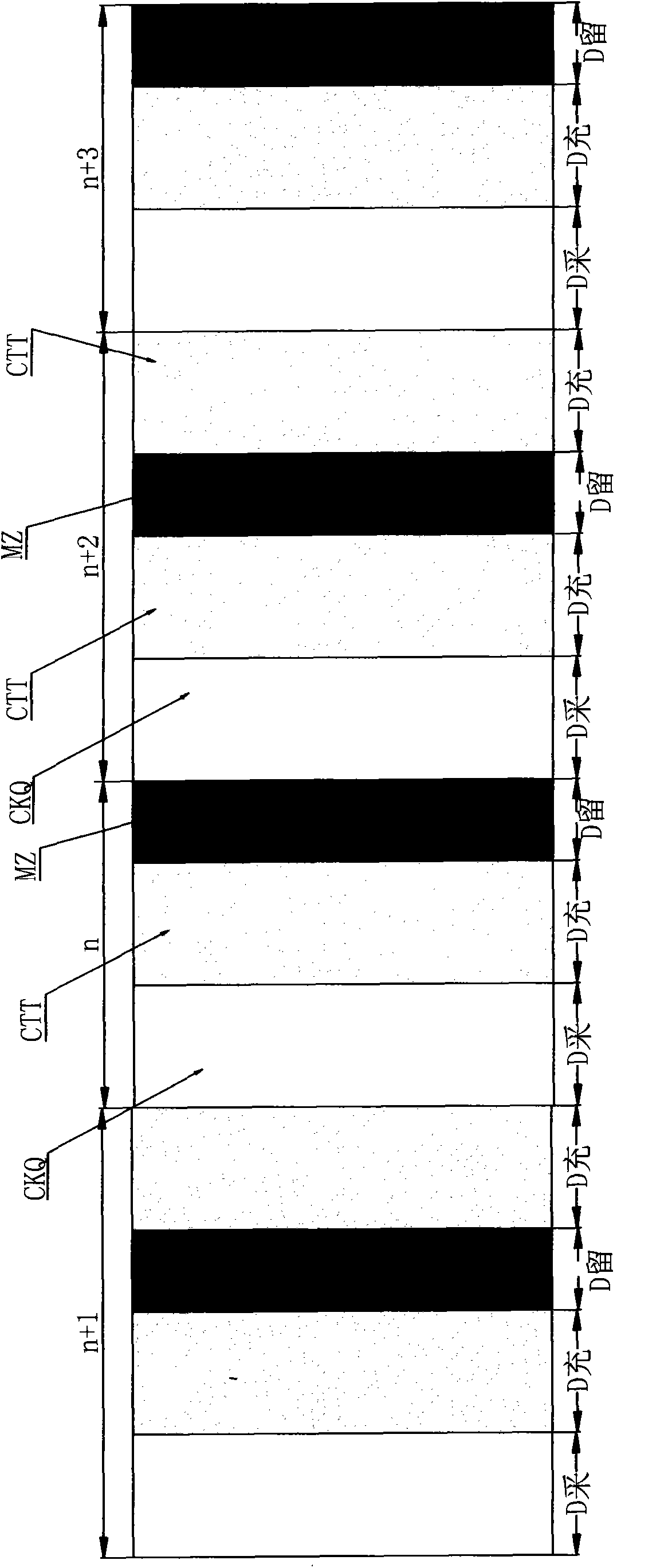

[0040] Such as Figure 1b and Figure 1b ' shows that the "mining-filling-retention" coupling coordinated mining method of the coal mine stratum movement control in this embodiment divides the coal mine mining area 1 into m mining units, where m is a positive integer; each mining unit adopts a double-sided filling mode For mining, the double-sided filling mode is to arrange a filling working face and a non-filling working face in sequence on the side where the coal pillar MZ is reserved, and another non-filling working face is arranged on the other side of the reserved coal pillar MZ; In the filling method mining unit area of the Nth mining unit n, the filling face mining is carried out and filled to form a filling body CTT; In goaf CKQ, n is a positive integer and m is less than or equal to n; two adjacent mining units use filling body CTT to be adjacent to goaf CKQ.

Embodiment 3

[0042] Such as Figure 1c As shown, the "mining-filling-retention" coupling coordinated mining method of the coal mine stratum movement control in this embodiment divides the coal mine mining area 1 into m mining units, where m is a positive integer; in the entire coal mine mining area 1, a part of mining The coal pillar MZ of the unit has a filling body CTT only on one side, and the coal pillar MZ of the other part of the mining unit has a filling body CTT on both sides; two adjacent mining units use the filling body CTT to be adjacent to the goaf CKQ or use The coal pillar MZ is adjacent to the goaf CKQ. Firstly, in the filling method mining unit area of the N mining unit n, the filling working face mining is carried out and filling is formed to form a filling body CTT; then, the non-filling working face mining is carried out in all the caving method mining unit areas of the N mining unit n, To form the goaf CKQ, n is a positive integer and m is less than or equal to n. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com