Horizontal suspension sludge air-lift backflow method

A technique of suspended sludge and airlift reflux, applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc. The method cannot efficiently complete the reflow task, the area is large, etc., to achieve the effect of long reflow route, ensuring consistency, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

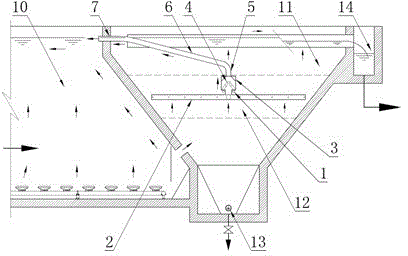

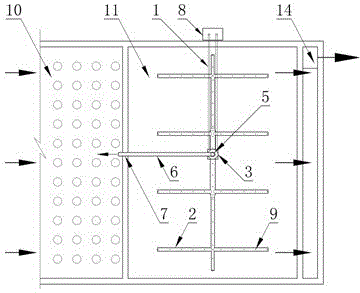

[0026] In the following, the present invention will be further described with reference to the accompanying drawings and the use of the horizontal suspended sludge air-lifting and reflux method of the present invention in conjunction with an activated sludge process sewage treatment tank as an example.

[0027] From figure 1 and figure 2 It can be seen from the figure that this reflux method adopts the surface-type air-lift reflux device applied for at the same time, which is mainly composed of a horizontal air inlet pipe 1, a closed suction pipe 2 connected horizontally and vertically, and a closed surrounding airtight pipe located above the middle of the suction pipe. The box body 3, the air nozzle 4 located in the box body, the standpipe elbow 5, the return inclined pipe 6, and the return flow through wall pipe 7 are composed, and are controlled by the compressed air control device 8 outside the pool.

[0028]The mud-water mixture from the biochemical treatment tank 10 en...

Embodiment 2

[0031] The sewage treatment capacity of a sewage treatment plant is 12,000 m 3 / d, there are 2 towers of 6000m each 3 / d V-type air-lifting integrated sewage treatment tank, the horizontal suspended sludge air-lifting and reflux method of the present invention is used to reflux the suspended activated sludge in the clarification area of the integrated treatment tank, and a total of 2 sets of surface-type air-lifting Micro power reflux device, each set consumes 0.995m of air 3 / min, the converted blower power consumption is 1.456Kw (single blower parameter Q=16.67 m 3 / min, P=58.8kPa, equipped with a 30kW motor with a frequency conversion device, the actual shaft power is 24. 4kW), and a good activated sludge return effect and sewage treatment effect have been obtained. The water quality is shown in the table below.

[0032] Sewage treatment plant design inlet and outlet water quality table

[0033] project COD BOD 5 SS TN NH 3 -N TP Influent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com