Novel label stripping mechanism

A peeling mechanism and label technology, which is applied in the direction of labels, labeling machines, and sending objects, can solve the problems of occasions that cannot adapt to the position change of product labels, and achieve the effects of saving costs, flexibly adjusting performance, and increasing revenue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

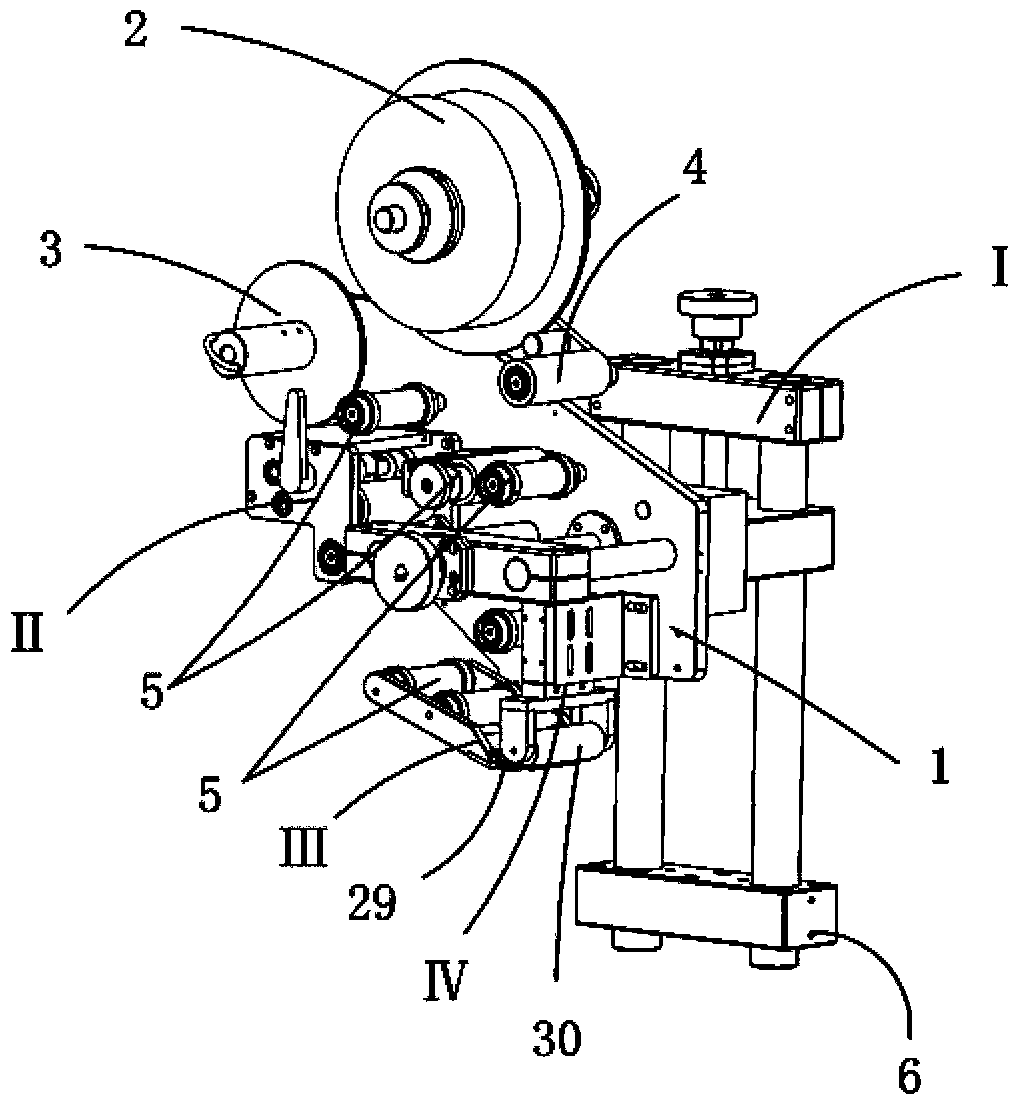

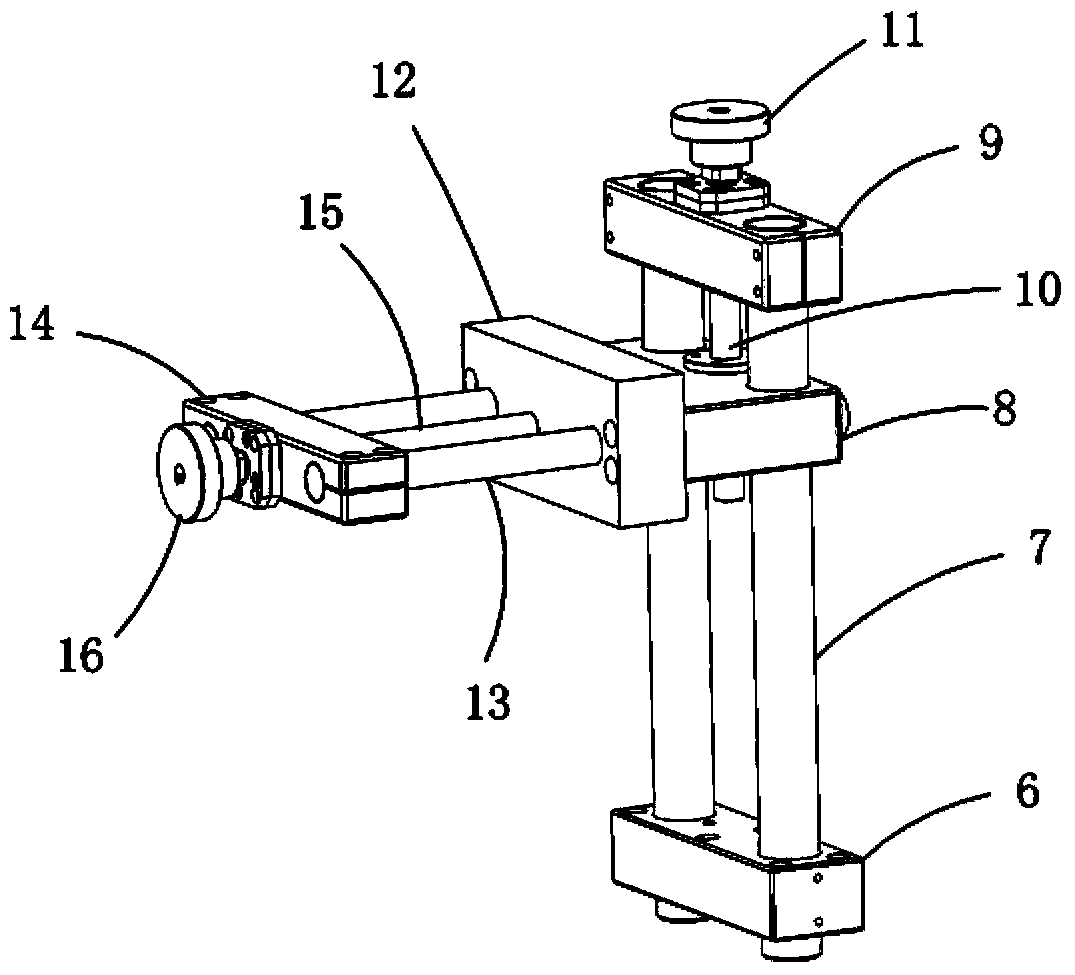

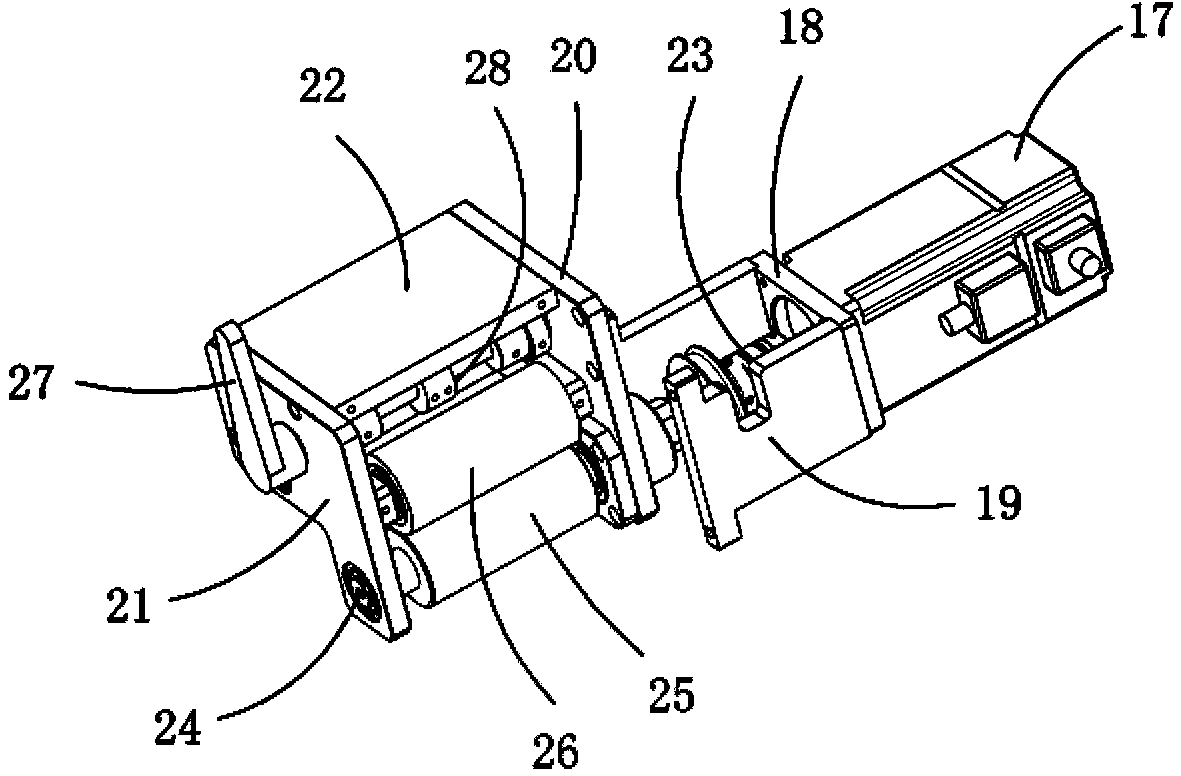

[0019] Examples, see attached Figure 1~3 , a new type of label peeling mechanism, which includes a support adjustment mechanism Ⅰ, a driving wheel pressing mechanism Ⅱ, a vertical plate 1, a discharge tray 2, a waste tray 3, a tensioning wheel 4, an idler wheel 5, a stripping mechanism Ⅲ and a pressing mechanism Device IV, the support adjustment mechanism includes a fixed plate 6, a vertical support column 7, a sliding plate 8, a longitudinal connection fixed plate 9, a longitudinal screw rod 10, a vertical manual adjustment valve 11, a horizontal fixed plate 12, a horizontal support column 13, Horizontally connect the fixed plate 14, the horizontal screw rod 15 and the horizontal manual adjustment valve 16. There are two longitudinal support columns, the lower part of the longitudinal support column is connected to the installation fixed plate, and the upper part passes through the sliding plate and is connected with the longitudinal connection fixed plate; A longitudinal ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com