U-shaped fastener double-card punched-card machine

A card punching machine and buckle technology, applied in external support, transportation packaging, packaging, etc., can solve the problems of frequent motor start-up, complex control system, etc., achieve the effect of simple and reliable cutting mechanism, improve production efficiency, and prevent accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

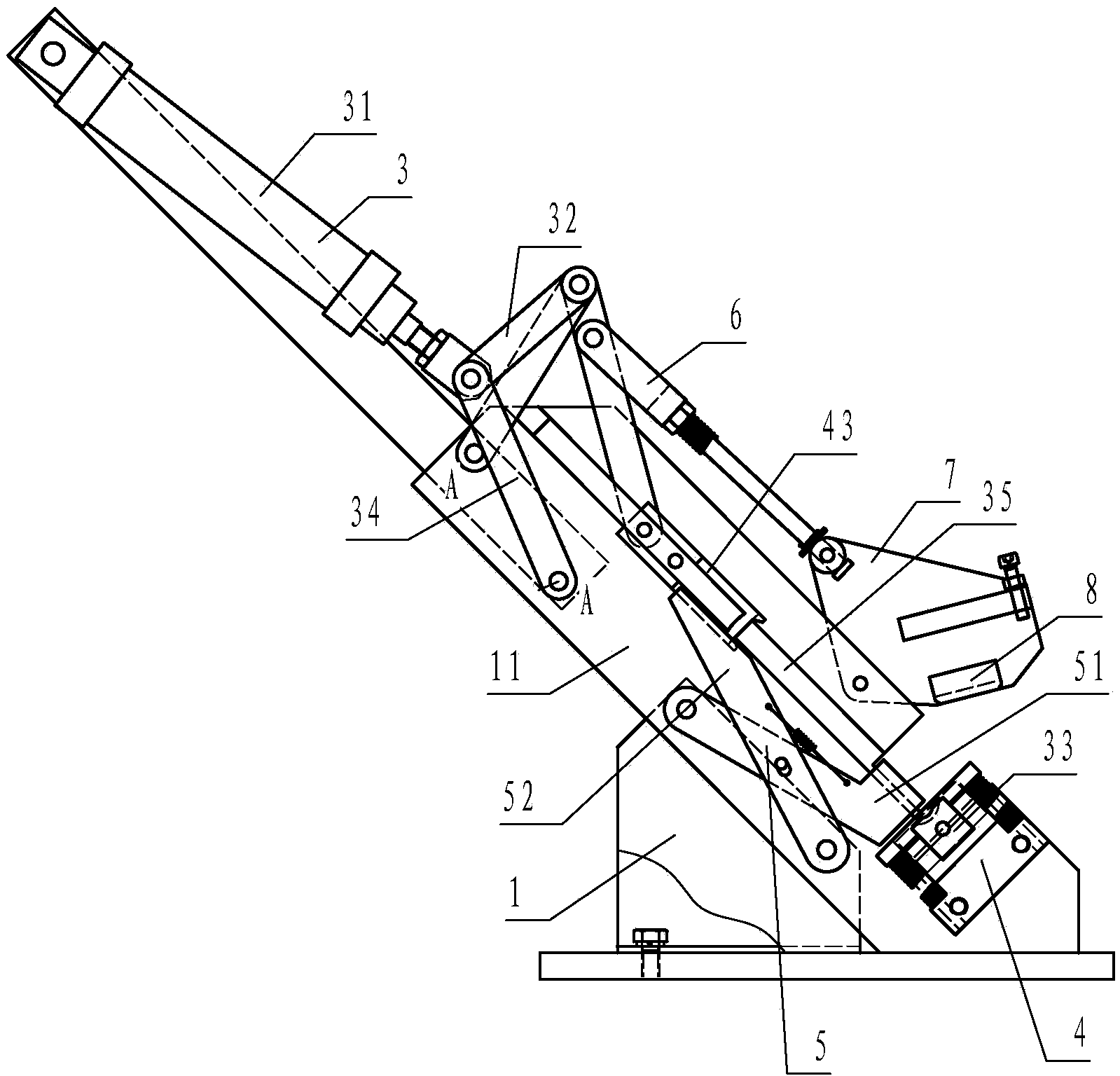

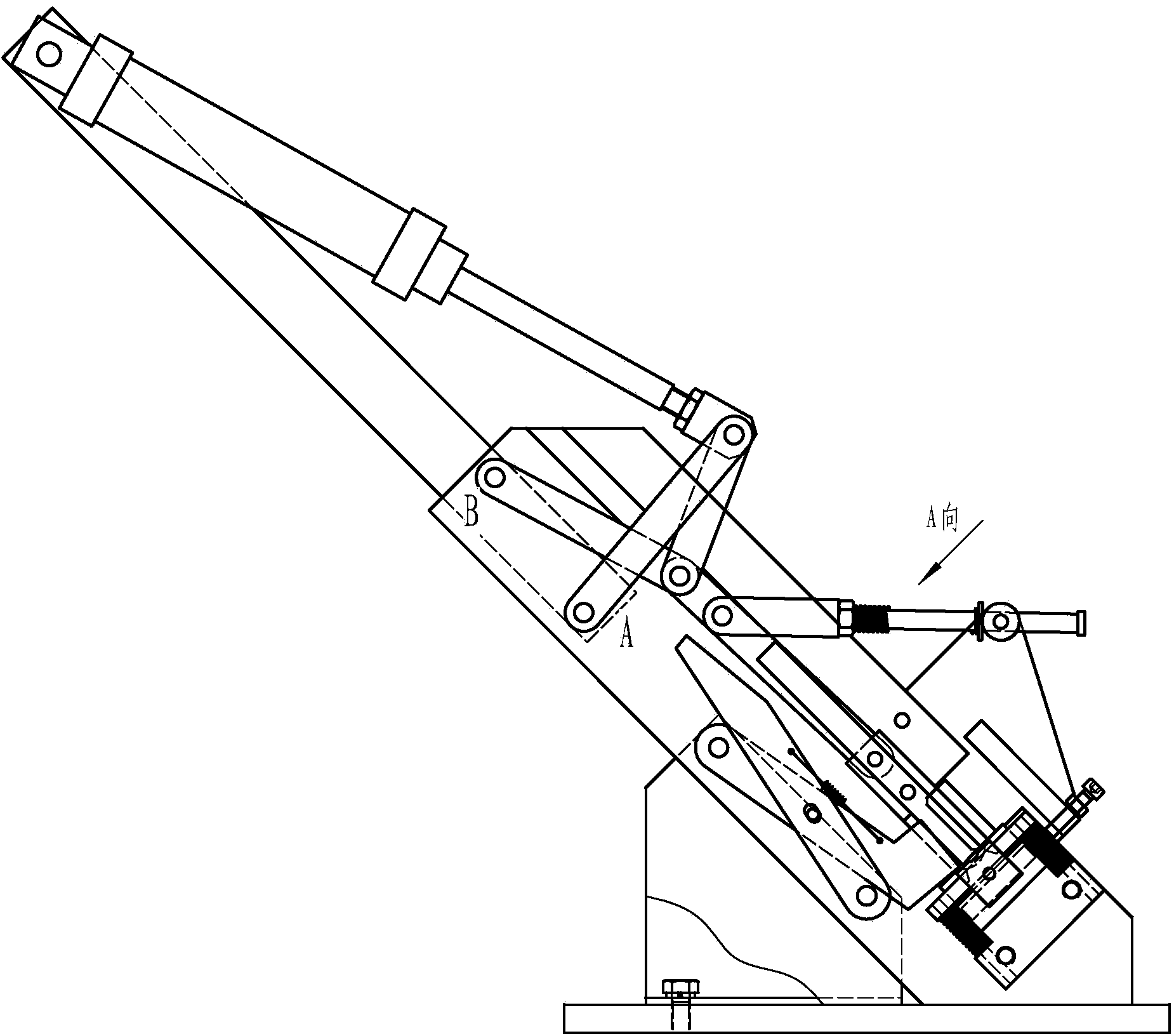

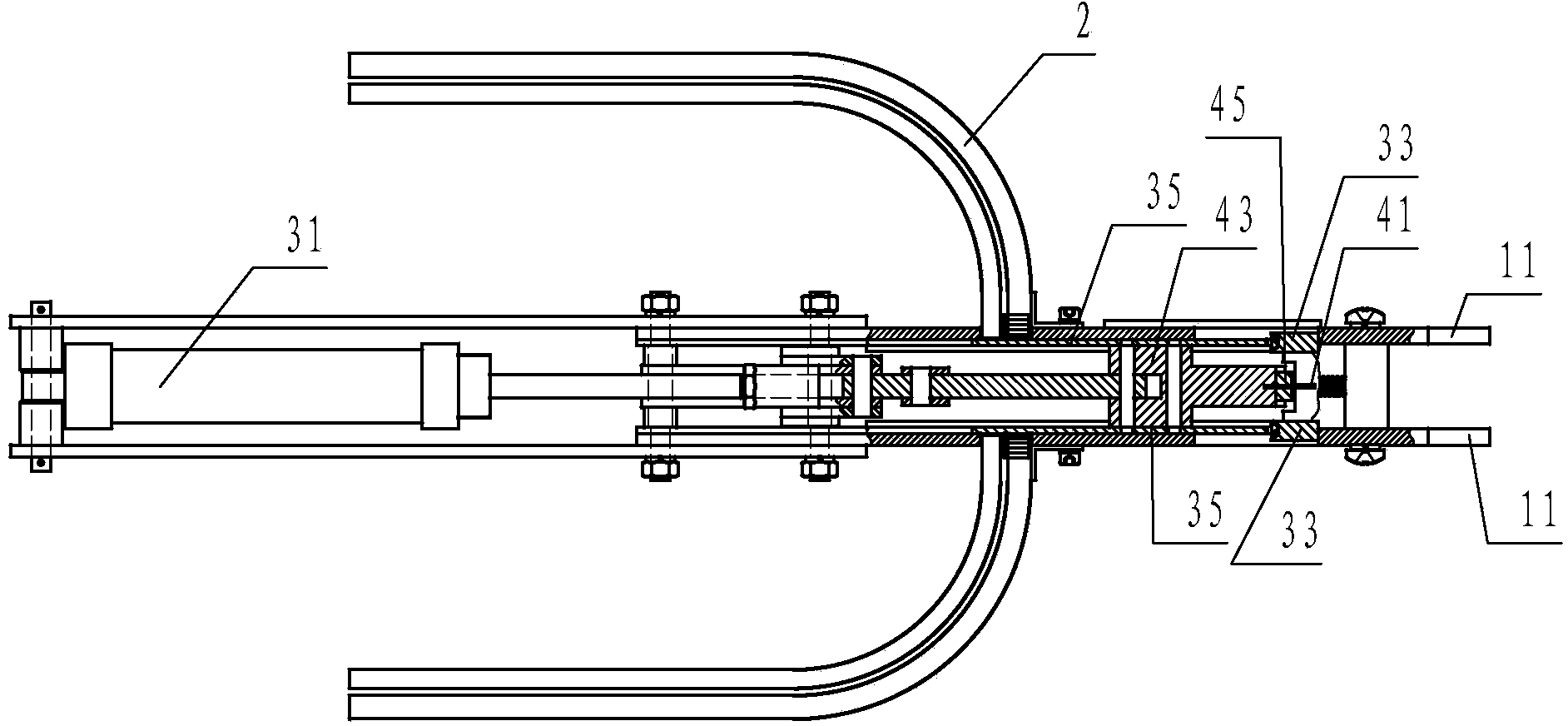

[0038]A U-shaped buckle double-card punching machine includes a frame 1, a U-shaped buckle installation slide 2, and a stamping mechanism 3, and a frame side plate 11 inclined from top to bottom is arranged on the frame. The stamping mechanism includes a cylinder 31, a double-linkage mechanism 32 connected left and right, and a forming die 33 arranged side by side. The double-linkage mechanism that moves with each other includes four connecting rods 34, wherein One end of the first and second connecting rods is hinged on the side plate of the frame sequentially from top to bottom, the other end of the second connecting rod is hinged at one point with the third connecting rod and the cylinder piston rod, and the other end of the first connecting rod It is hinged at one point with the other end of the third connecting rod and the fourth connecting rod. The other end of the fourth connecting rod is connected with two pressure rods 35 arranged side by side. The two pressure rods ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com