Full-automatic frameless picture cutting and assembling integrated machine

A frameless painting, fully automatic technology, applied in decorative arts, special decorative structures, pasting, etc., can solve the problems of standard deviation, high labor cost, poor quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

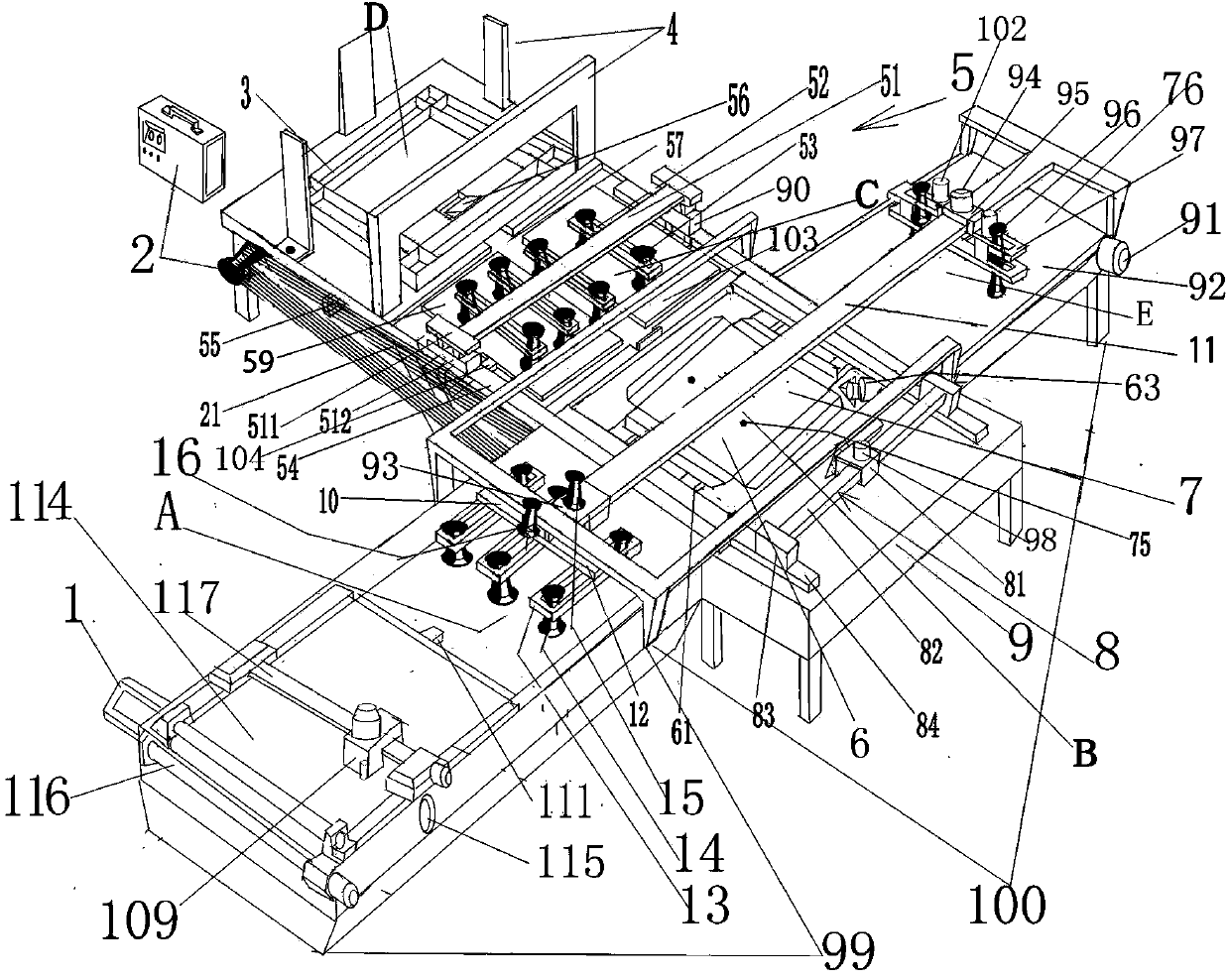

[0016] see figure 1 , figure 2 , image 3 , Figure 5 and Figure 6Shown, the present invention is made up of cutting system 99 and assembly system 100 two parts, cutting system 99 and assembly system 100 are connected by frame 9, and cutting system 99 is composed of man-machine automation programming control device 1, laser Cutting head 109, conveyor belt device 114, suction system 115, dotted line cutting device 145, first rail assembly 117, pneumatic and electric device 2, wooden strip module holding basket 3, module bucket box 4, automatic suction frame device 5, Automatic assembly device 6, picture folding plate 7, automatic binding robot arm 8, frame 9, automatic painting device 10 and finished product recovery device 76 are composed of the laser cutting head 109, conveyor belt device 114, and air suction system 115 , dotted line cutting device 145, first rail assembly 117, man-machine automation programming control device 1, pneumatic and electric device 2, wooden ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com