Mechanical arm type honing machine

A manipulator and honing technology, applied in the field of honing machines, can solve the problems of energy consumption, large dust, high noise, etc., and achieve the effect of reducing pollution, simple operation and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

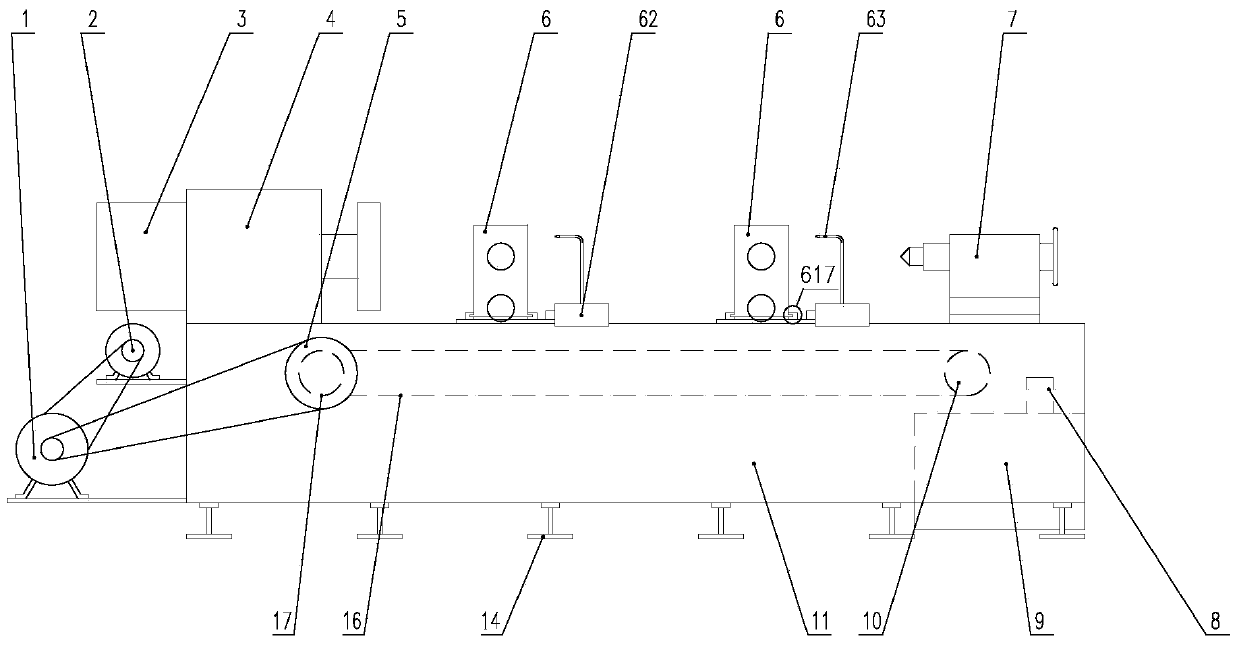

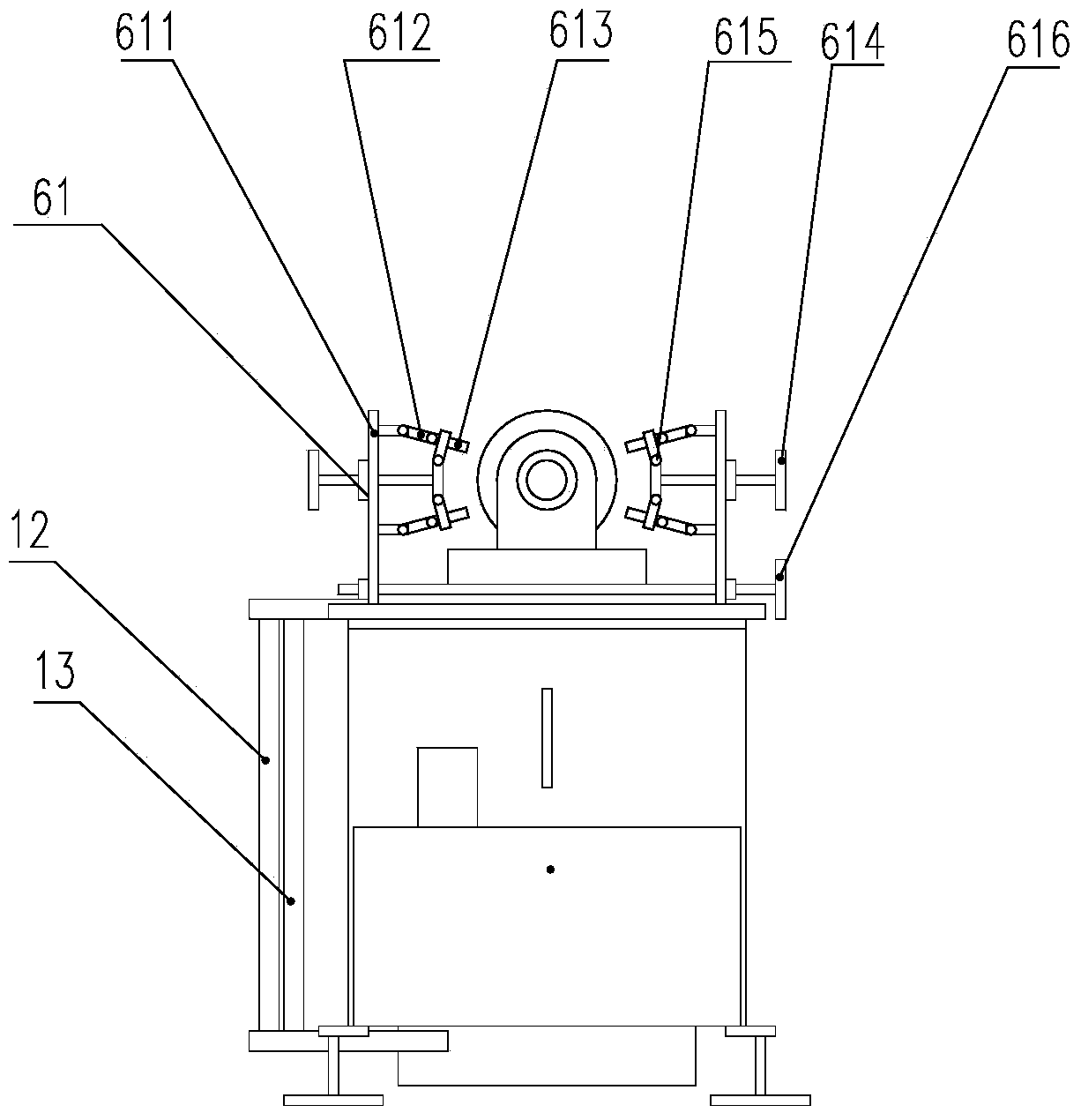

[0027] A manipulator-type honing machine, the honing machine includes a bed 11, one end of the bed 11 is provided with a travel reducer 1 and a travel motor 2, the travel reducer 1 and the travel motor 2 are driven by a chain, and the travel reducer 1 is driven by a drive The chain 17 is linked with the walking transmission wheel 5 on the outer wall of the bed 11, the other end of the bed 11 is provided with a passive sprocket 10, the walking transmission wheel 5 and the passive sprocket 10 are provided with a walking chain 16, and the two ends of the bed 11 are respectively provided with Main reducer 4 and tailstock 7 are arranged, main reducer 4 is also connected with main motor 3, and two grinding head devices 6 are arranged between main reducer 4 and tailstock 4, and each grinding head device 6 includes following The manipulator 61 arranged symmetrically on the central axis of the bed 11 and the operation control box 62 provided on one side of the manipulator 61 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com