Production method of baked puffing shrimp chips

A technology of baking and puffing and production methods, which is applied in the field of food processing, can solve problems affecting human health, product quality during storage time, etc., and achieve the effects of easy control, simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

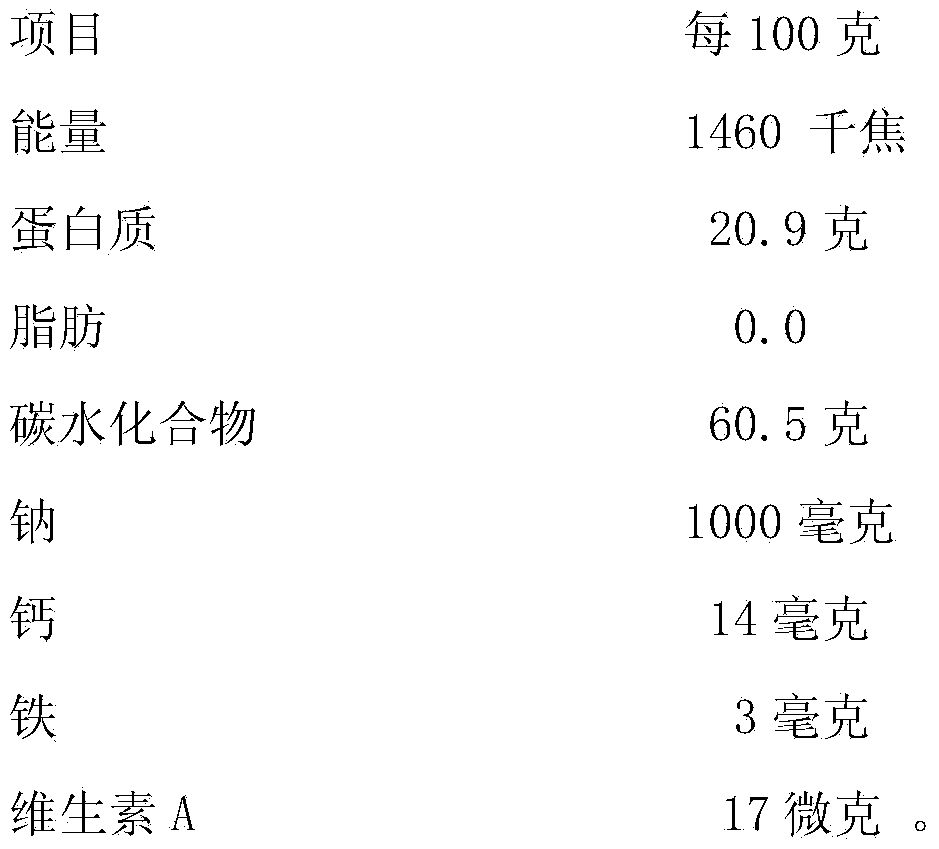

[0027] Embodiment 1, a kind of production method of baked puffed shrimp chips, carries out following steps successively:

[0028] 1), ingredients:

[0029] The main ingredient is composed of the following components by weight:

[0030] Freeze-dried shrimp powder 86.23%, soybean protein powder (or wheat flour) 2.21%, corn starch 2.20%, L-glutamic acid 0.5%, sugar 4.9%, salt 1.47%, butter (need to be melted in water beforehand) 0.68%, soak Powder 1.76% and calcium sulfate (or calcium carbonate) 0.05%; mix the above ingredients evenly to obtain the main ingredient;

[0031] 2) Add water accounting for 20% of the total weight of the main material into the main material, mash it evenly, and let it stand for 2 hours to obtain a slurry;

[0032] 3) Add water accounting for 5% of the total weight of the main ingredients to the slurry obtained in step 2) and mix well, then pour it into a mold (a special mold with the actual required shape), spread it flat, and put it in 0.5-1 Compac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com