A composite material chimney connection node and method

A composite material, connecting node technology, applied in combustion methods, combustion product treatment, exhaust gas devices, etc., can solve the problems of large on-site work workload, flange cracking damage, poor ability to eliminate stress, etc., to reduce direct Contact area, reduce anti-corrosion cost, improve the effect of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

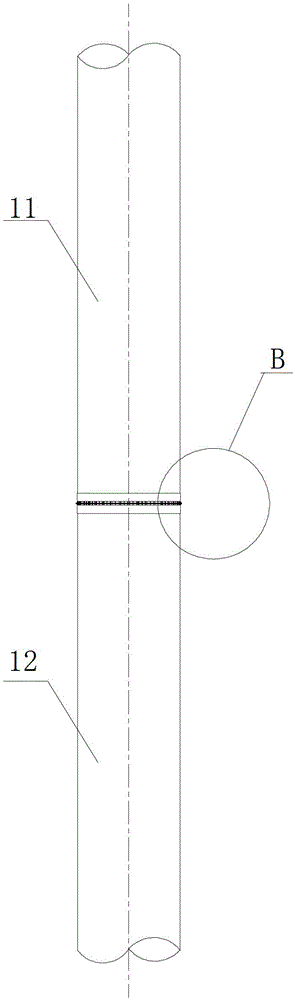

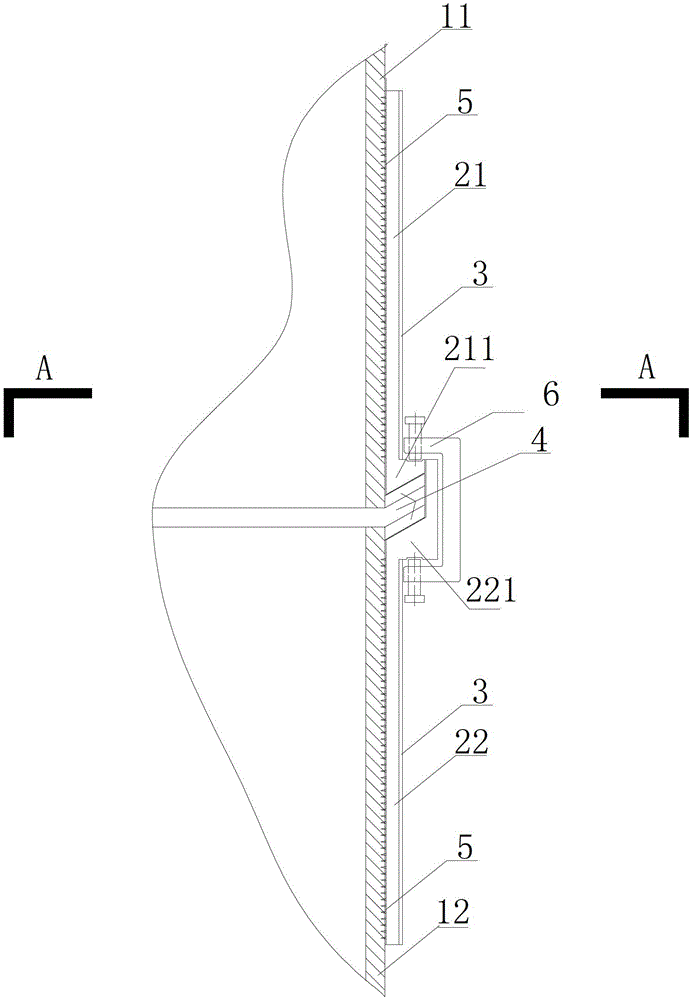

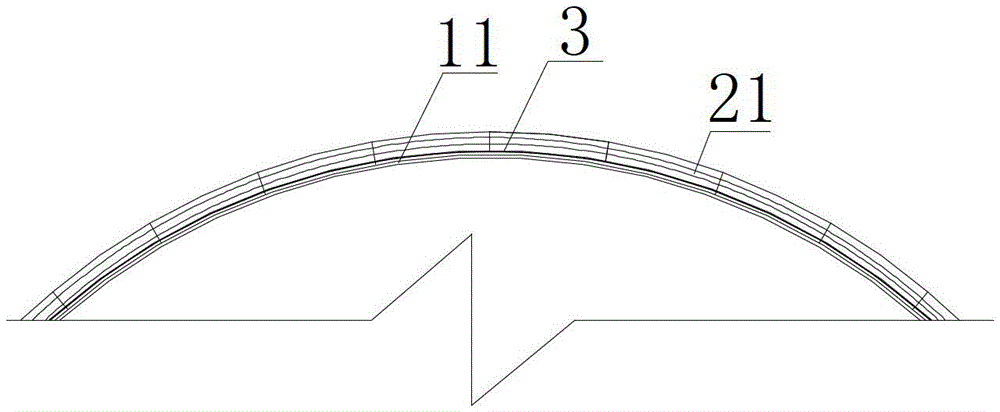

[0055] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 Shown:

[0056] First, use a grinder to grind off the non-slip coating in the node connection area of the first cylinder 11 and the second cylinder 12 of the composite material chimney. When grinding, care should be taken to control the grinding depth, preferably 0.5mm±0.1mm;

[0057] Next, calibrate the size of the nodes on the first cylinder 11 and the second cylinder 12, and apply epoxy glue on the node connection between the first cylinder 11 and the second cylinder 12, with a thickness of 0.5mm±0.1mm appropriate;

[0058] Next, place the first arc-shaped stabbing plate 21 on the outer surface of the node connection area of the first cylinder 11, the first connecting portion 211 is close to the connecting end of the first cylinder 11, and the barbed spine of the first arc-shaped stabbing plate 21 Facing the first cylinder body 11, press the tho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com