A linear flow plug gas valve

A technology of gas valve and flow, which is applied in the direction of the cock including the cut-off device, valve device, engine components, etc. It can solve the problems of sudden change of intake air, enlarged flame, and different cross-sectional area of intake air, so as to achieve stable and smooth intake air. The effect of air velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

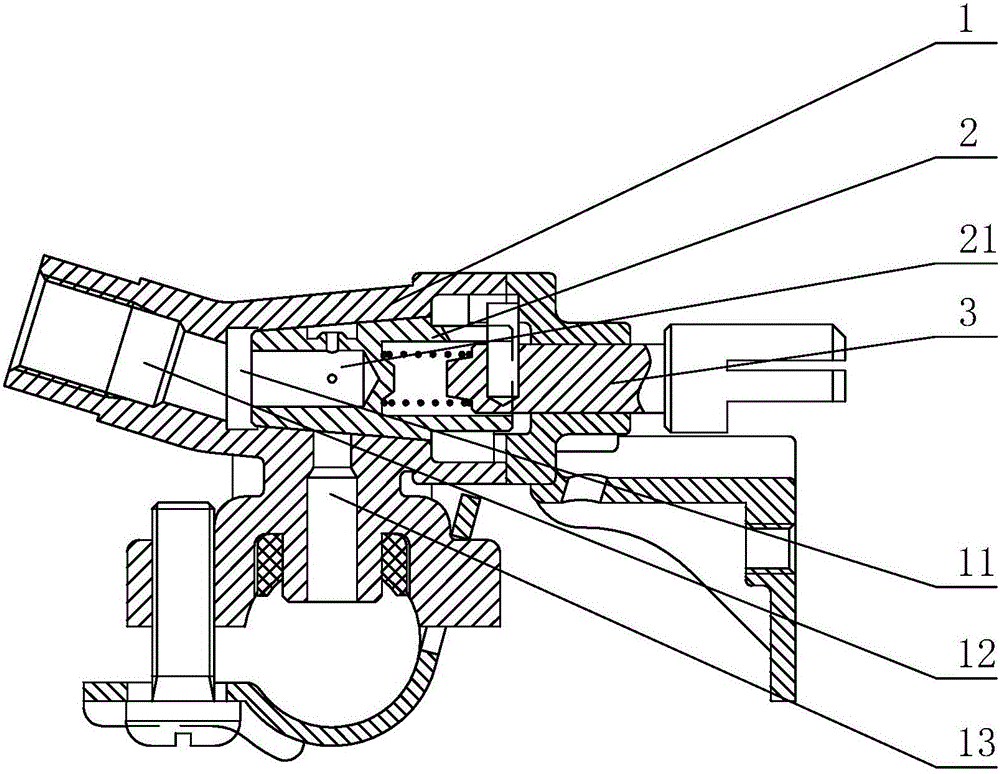

[0016] A preferred embodiment of a linear flow cock gas valve of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0017] like figure 1 As shown, the linear flow cock gas valve mainly includes a valve body 1 and a cock 2. The left end of the valve body 1 is provided with an air outlet 12, and the right end is provided with a cock chamber 11. The cock chamber 11 communicates with the air outlet 12. The valve body 1 is opened from bottom to top. An air inlet 13, the air inlet 13 communicates with the cock chamber 11.

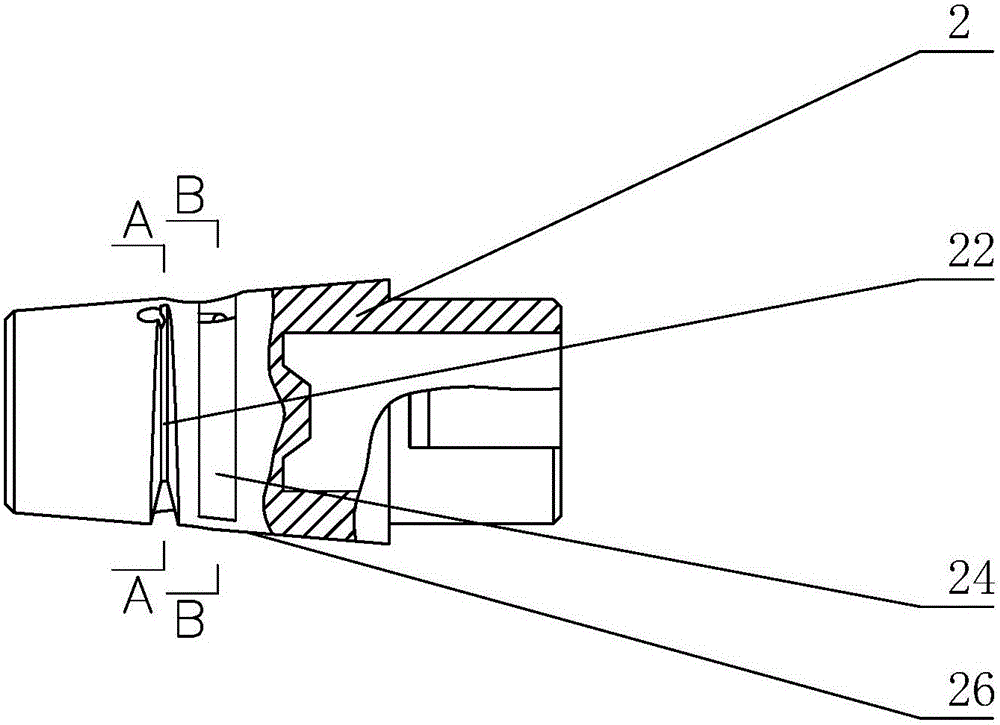

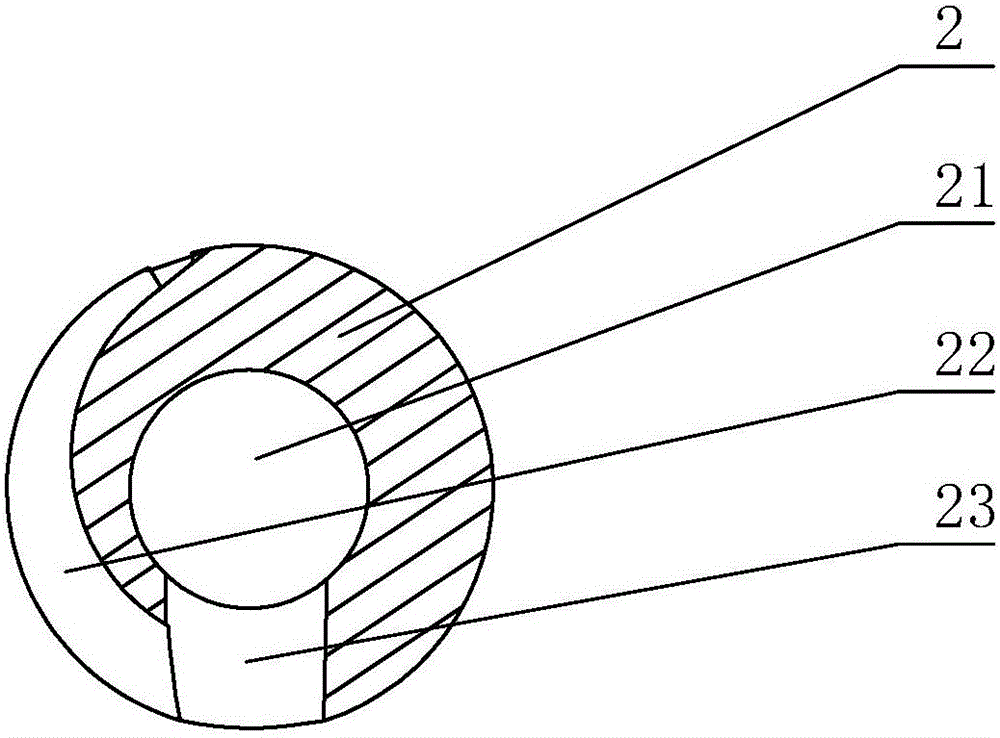

[0018] The cock cavity 11 is a truncated conical cavity, in which the cock 2 is installed, and the rotating surface 26 of the cock 2 is also truncated conical, and its shape is in sealing fit with the cock cavity 11 . The air inlet 13 is aligned with the rotating surface 26 . A cylindrical gas channel 21 is opened inside the cock 2 , and the position is located inside the rotating surface 26 , one end is clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com