Connector shaft

A connector and front-end technology, which is applied in the field of connecting parts, can solve the problems that the connector shaft is easily deformed and affects the service life, etc., and achieves the effect of simple and reliable structure, easy assembly, and good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

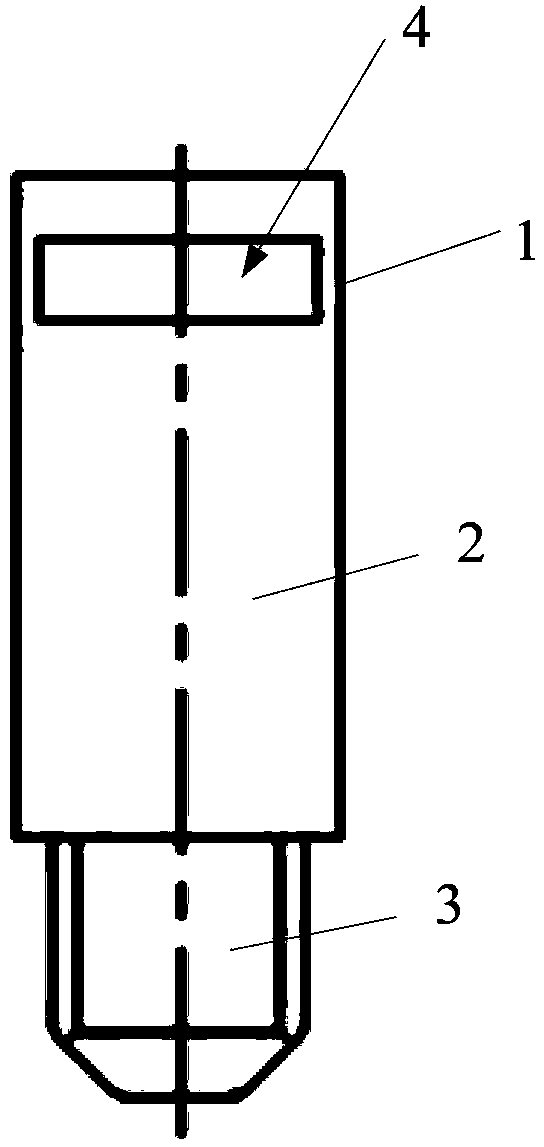

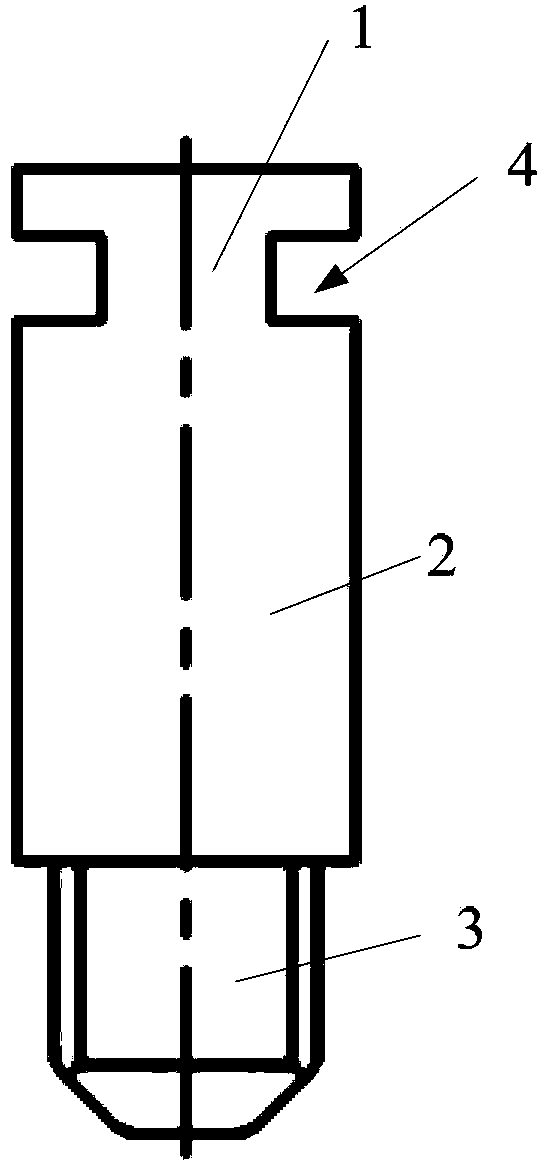

[0019] like figure 1 , Figure 2, image 3 , Figure 4 Shown: a connector shaft, including an integrally formed front section 1, middle section 2 and rear section 3, the front section 1 and middle section 2 are cylindrical, and a groove 4 is opened on the peripheral surface of the front section 1; the rear section The main body of the section 3 is in the shape of a square prism, and the end of the rear section 3 is in the shape of a square prism, which is convenient for inserting into the shaft hole of the required connecting parts. The four side edges of the rear section 3 are provided with chamfers.

[0020] Further, there are two grooves 4, which are oppositely and symmetrically opened on the peripheral surface of the front section 1 of the connector shaft.

[0021] In order to improve the working reliability of the connector shaft under high temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com