Bridge inspection car running track manual shifter

A technology of bridge inspection vehicle and conversion device, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of long maintenance period, complex structure of the slewing system, poor mass production economy, etc., and achieve convenient disassembly and maintenance, simple and innovative structure , The effect of convenient and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

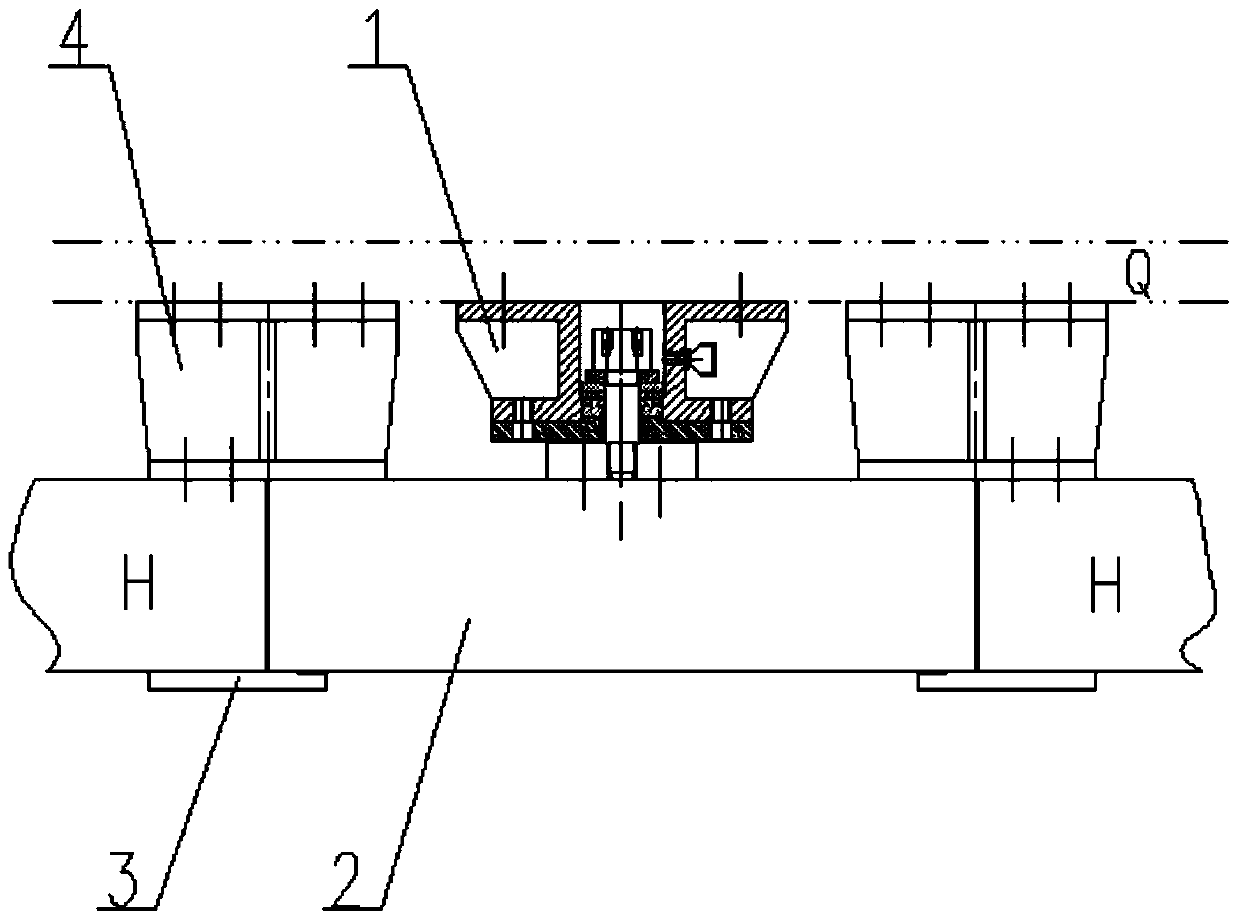

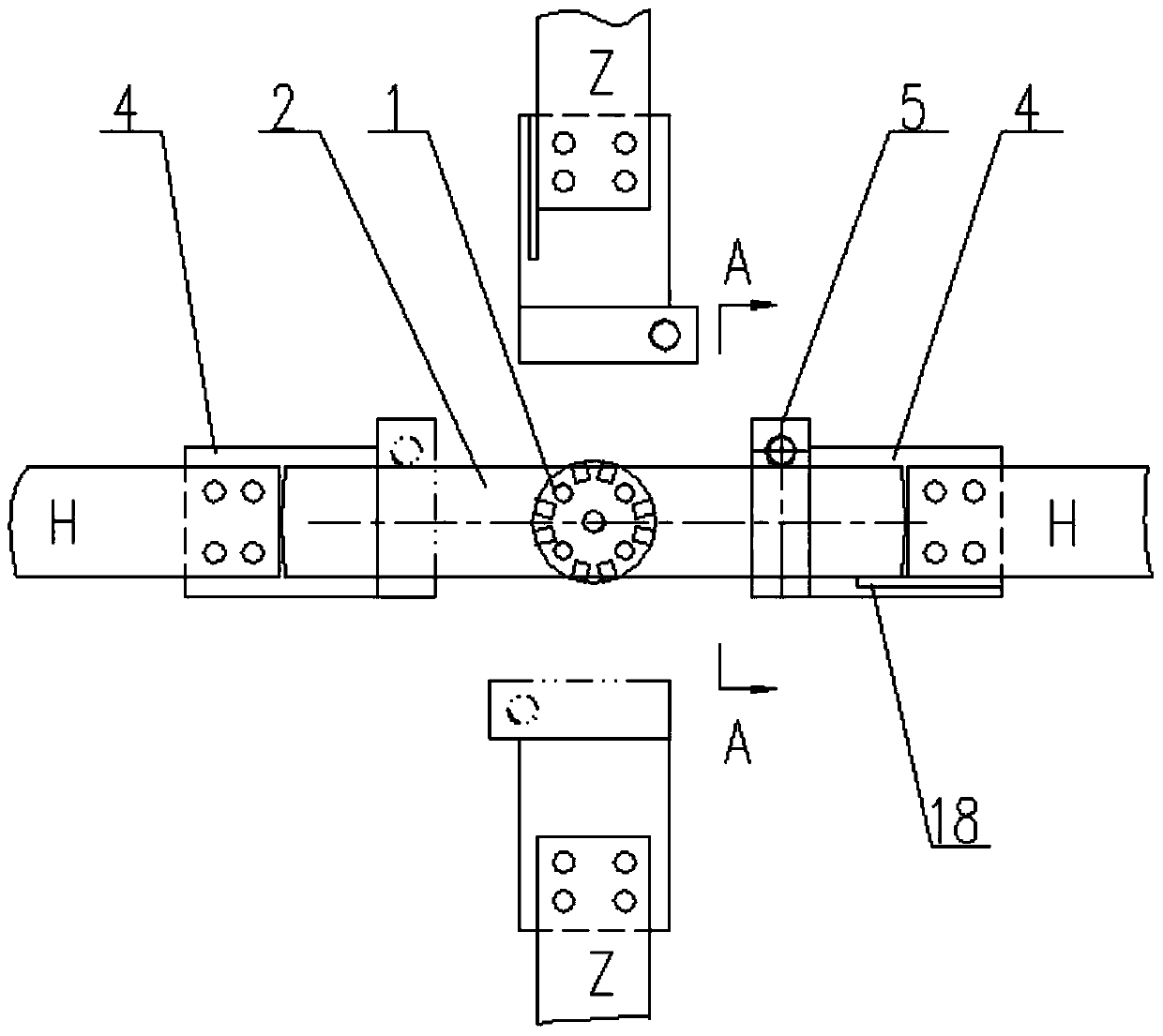

[0019] The present invention is a manual changing device for running tracks of a bridge inspection vehicle, which can realize the transformation and docking of two running tracks at an angle on the same horizontal plane within 360°. Taking the track changing situation as an example, how the present invention is implemented is further explained in conjunction with the accompanying drawings:

[0020] Such as figure 1 and figure 2 , the present invention is a kind of manual changing device for the running track of the bridge inspection vehicle, comprising: a rotating support 1, a rotating track 2, a fixed connection support 4, an upper rotating positioning mechanism and a lower rotating support block 3;

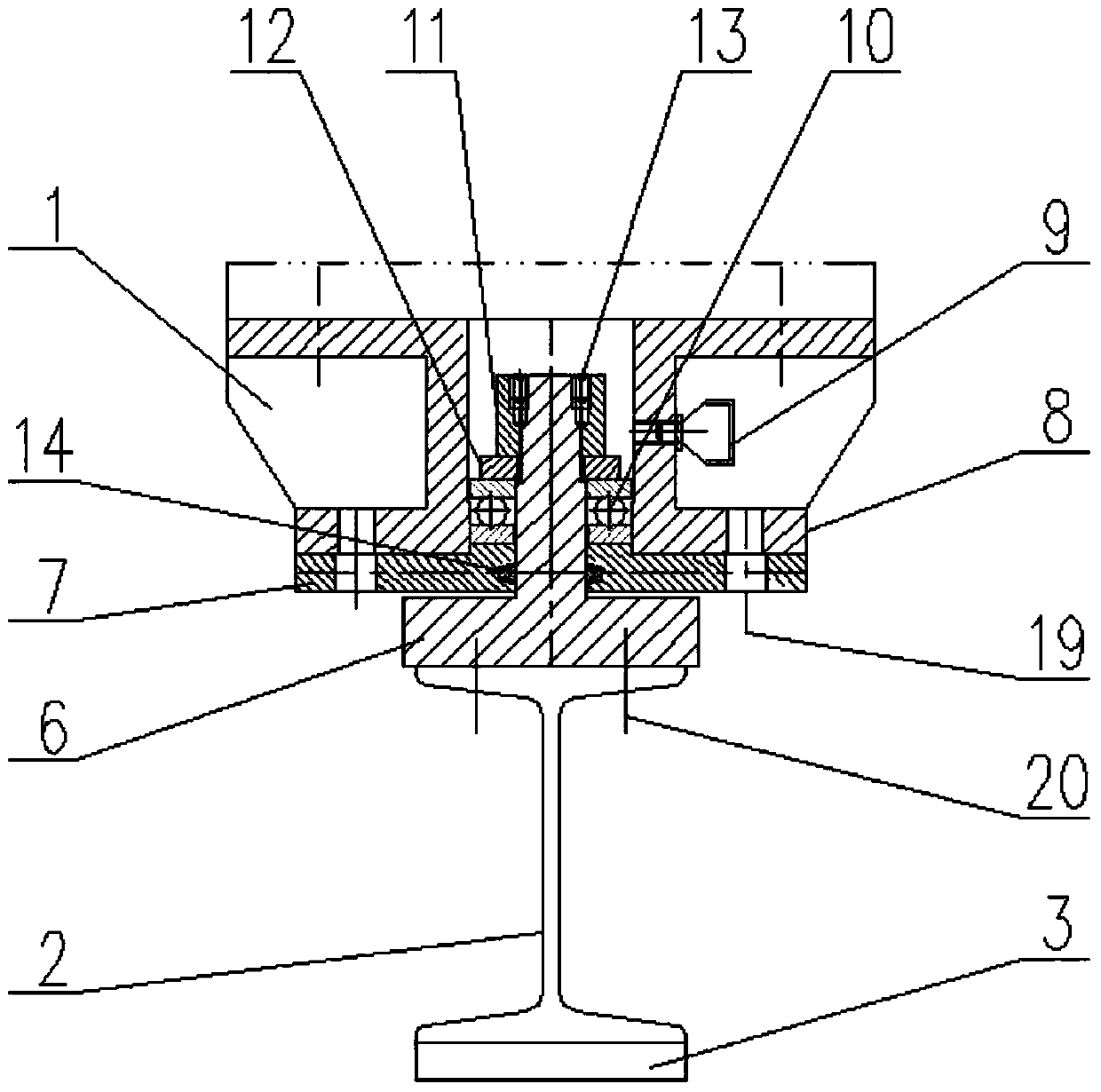

[0021] Such as image 3 , the rotating support 1 is composed of a combined coupling shaft and a bearing seat 8; the combined coupling shaft is composed of a coupling shaft 6, a bearing 10, a bearing baffle 7, a round nut 11 and a backing plate 12, and the coupling shaft 6 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com