Strengthened low-bone china porcelain and production method thereof

A technology for bone china and porcelain, which is applied in the field of daily necessities of porcelain and its production, and can solve the problems of difficult cleaning, low strength, and scratches on cutlery and forks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

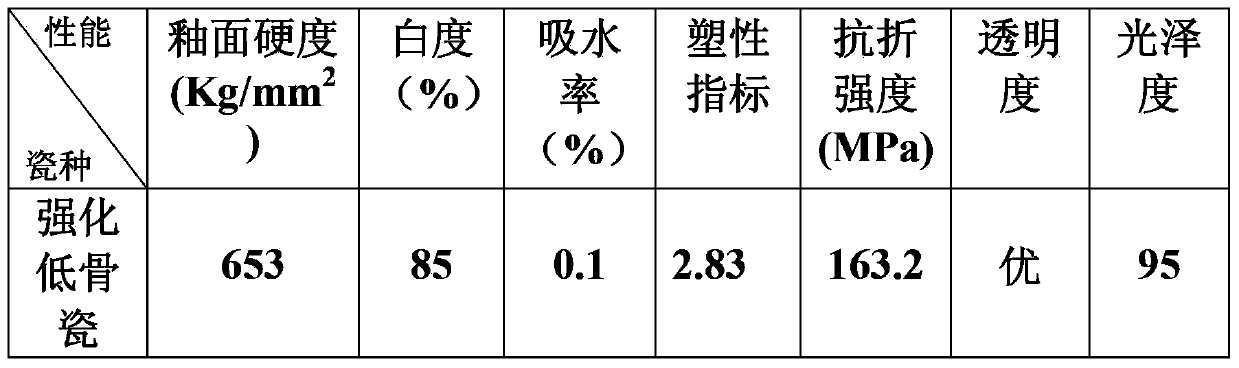

Examples

Embodiment 1

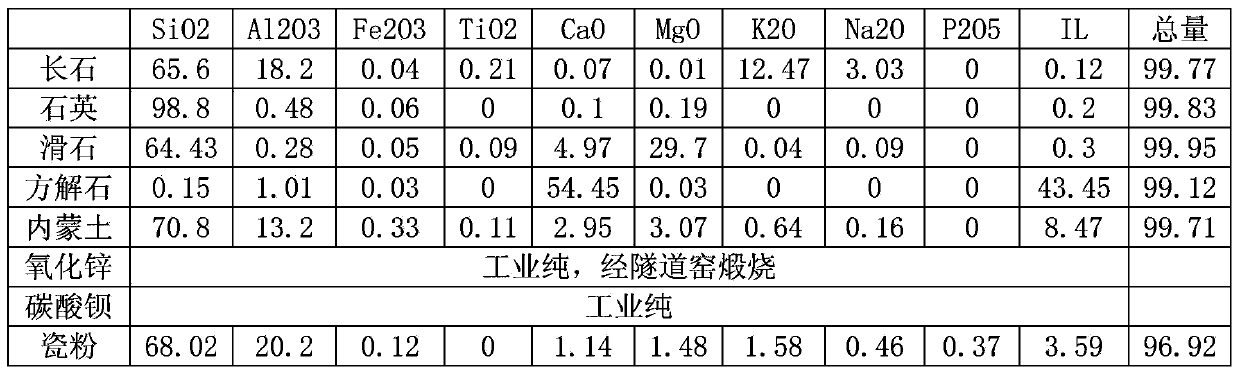

[0017] Reinforced low-bone china porcelain, which is made from blanks and glazes made of the following raw materials in weight ratios: 25 parts of quartz, 20 parts of Datong soil, 3 parts of talc, and 10 parts of Fujian soil 5 parts of Hunan soil, 2 parts of alumina, 4 parts of bone meal, 8 parts of feldspar, and 3 parts of Inner Mongolia soil; the raw material weight ratio of the glaze is: 8 parts of quartz, 35 parts of feldspar, 4 parts of talc, 4 parts of Inner Mongolia soil, 10 parts of calcite, 3 parts of zinc oxide, 2 parts of barium oxide, 15 parts of porcelain powder.

[0018] The method for producing above-mentioned strengthened low-bone china porcelain, it comprises the following steps:

[0019] 1) Preparing the billet: Weigh the raw materials according to the raw material weight ratio of the billet and mix them evenly, then ball mill the mixture, the ratio of material:ball:water is 1:1.5:1.2; ball mill the mixture until the fineness is 250 mesh For mud, the sieve r...

Embodiment 2

[0025] Reinforced low-bone china porcelain, which is made from blanks and glazes made of the following raw materials in weight ratios: 33 parts of quartz, 25 parts of Datong soil, 5 parts of talc, and 15 parts of Fujian soil 10 parts of Hunan soil, 5 parts of alumina, 10 parts of bone meal, 10 parts of feldspar, 5 parts of Inner Mongolia soil; the raw material weight ratio of the glaze is: 10 parts of quartz, 40 parts of feldspar, 6 parts of talc, 6 parts of Inner Mongolia soil, 13 parts of calcite, 5 parts of zinc oxide, 4 parts of barium oxide, 20 parts of porcelain powder.

[0026] The method for producing above-mentioned strengthened low-bone china porcelain, it comprises the following steps:

[0027] 1) Preparing the billet: Weigh the raw materials according to the raw material weight ratio of the billet and mix them evenly, then ball mill the mixture, the ratio of material:ball:water is 1:1.7:1.2; ball mill the mixture until the fineness is 250 mesh For mud, the sieve r...

Embodiment 3

[0033] Reinforced low-bone china porcelain, which is made from blanks and glazes made of the following raw materials in weight ratios: 29 parts of quartz, 23 parts of Datong soil, 4 parts of talc, and 13 parts of Fujian soil 7 parts of Hunan soil, 4 parts of alumina, 7 parts of bone meal, 9 parts of feldspar, 4 parts of Inner Mongolia soil; the raw material weight ratio of the glaze is: 9 parts of quartz, 37 parts of feldspar, 5 parts of talc, 5 parts of Inner Mongolia soil, 12 parts of calcite, 4 parts of zinc oxide, 3 parts of barium oxide, 18 parts of porcelain powder.

[0034] The method for producing above-mentioned strengthened low-bone china porcelain, it comprises the following steps:

[0035] 1) Preparing the billet: Weigh the raw materials according to the raw material weight ratio of the billet and mix them evenly, then ball mill the mixture, the ratio of material:ball:water is 1:1.6:1.2; ball mill the mixture until the fineness is 250 mesh For mud, the sieve resid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com