Energy-saving type positive and negative pressure pneumatic air seal machine

An energy-saving, air-shutoff technology, applied in conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problems of destroying the balance of the wind network, the impeller is easy to get stuck, and the structure is complicated, so as to save the air source and coordinate. Good, ensure the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

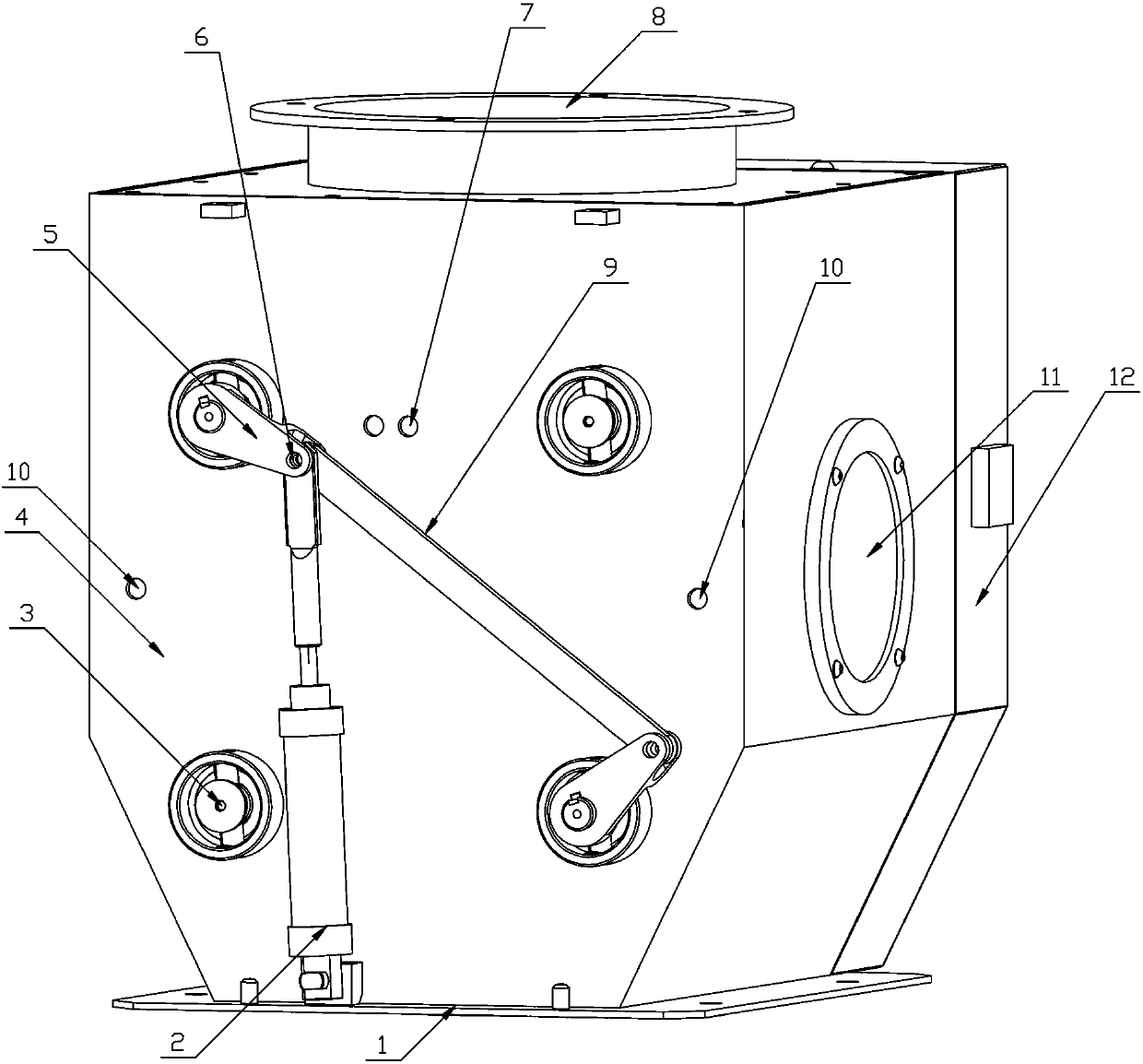

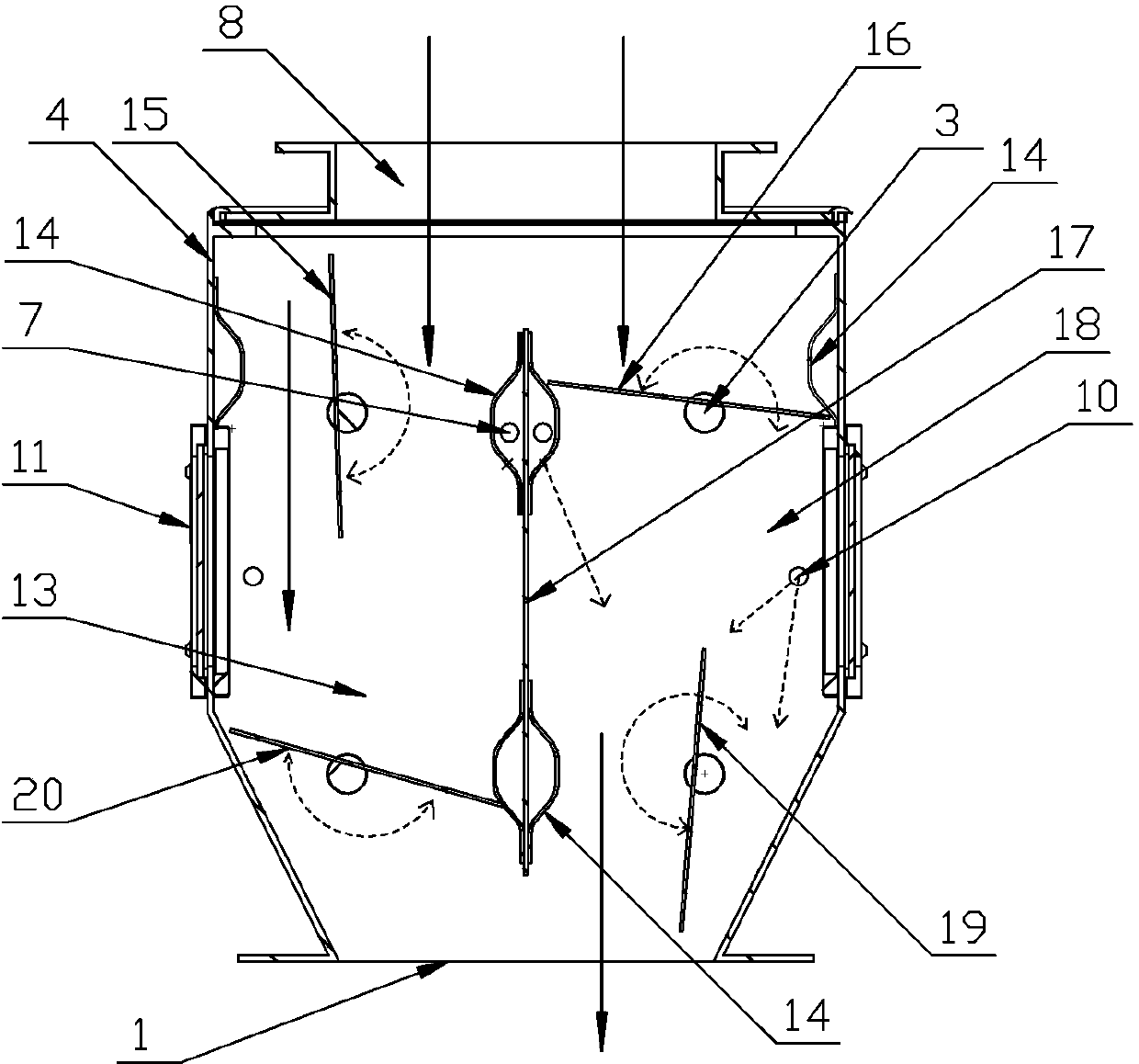

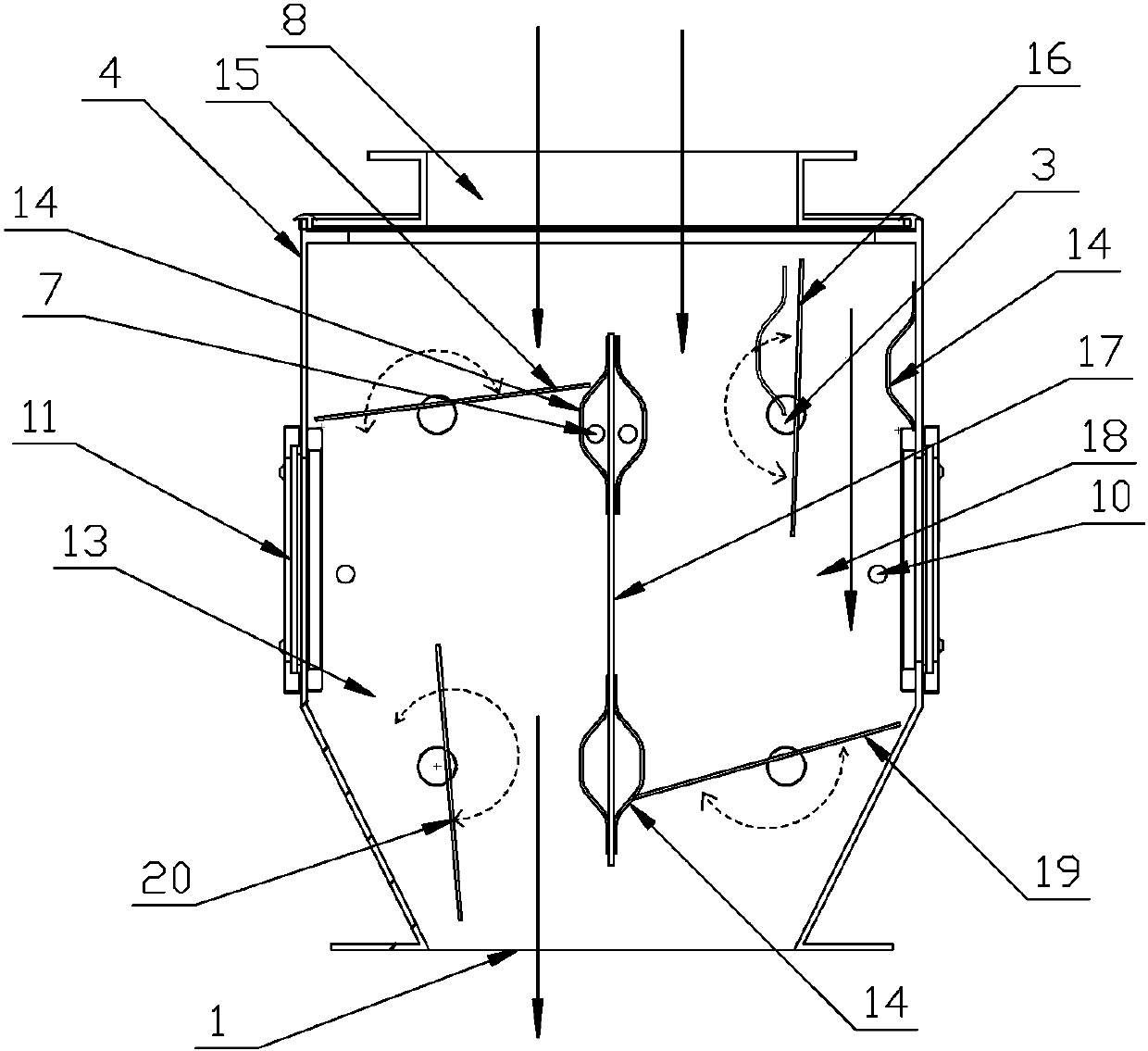

[0027] see figure 1 , 2 , 3, the present invention comprises housing 4, and the top of housing 4 is provided with feed inlet 8, and the bottom is provided with discharge outlet 1, is provided with the clapboard 17 vertically arranged in the middle part of housing 4 cavity and housing 4 The inner cavity is divided into front and rear two discharge passages 18 and 13, and upper and lower blades 15, 16, 19, 20 are installed in each discharge passage through the upper and lower rotating shafts 3. Sealing plates 14 are provided at the closing positions of the upper and lower blades on both sides, and sealing plates 14 are located at the closing positions of the upper blades on the front and rear side plates of the housing 4. , rear sealing plate 14, arc-shaped design (see figure 2 , image 3), and three jet holes 21 are respectively opened on the two arc-shaped sealing plates 14. , on the housing 4 corresponding to the front and rear air intake passages, there are air inlets 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com